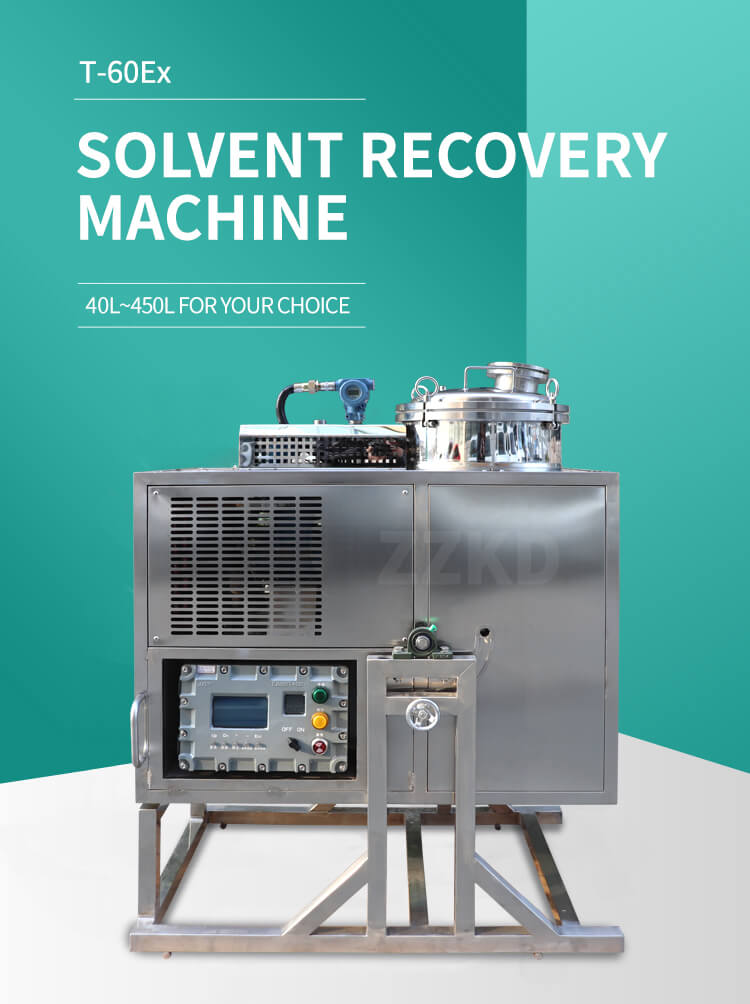

Solvent Recycler for Sale

ZZKD manufactures durable, high-quality solvent recycler and has been selling them to customers worldwide for over 33 years. ZZKD offers CE certified solvent recycler to help you grow your business and obtain accurate reaction data. You will be satisfied with the performance of your ZZKD solvent recycler because we use well-known brand components to build your solvent recycler.

Capacity: 40 L

Power: 4 kW

Temp Range: 5~200℃

Recovery: 95%

Application: Suitable for medium-sized experiments in university laboratories.

Function: Efficiently recovers solvents through distillation.

Capacity: 60 L

Power: 5 kW

Temp Range: 5~200℃

Recovery: 95%

Application: Versatile for analysis across various industries.

Function: Ideal for tasks like recrystallization.

Capacity: 80 L

Power: 6 kW

Temp Range: 5~200℃

Recovery: 95%

Application: Ensures safety in handling large-scale applications.

Function: Suitable for tasks like heavy concentration and drying.

Capacity: 100 L

Power: 8 kW

Temp Range: 5~200℃

Recovery: 95%

Application: Reliable choice for various experiments.

Function: Performs tasks such as distillation.

Capacity: 250 L

Power: 16 kW

Temp Range: 5~200℃

Recovery: 95%

Application: Designed for handling large-scale applications efficiently.

Function: Suitable for tasks such as distillation and recovery in bulk.

Capacity: 450 L

Power: 32 kW

Temp Range: 5~200℃

Recovery: 95%

Application: Ensures safety in handling extensive volumes.

Function: Ideal for heavy-duty tasks such as distillation and recovery on a large scale.

Application

Solvent recyclers find diverse applications in industrial cleaning, paint and coating operations, laboratory settings, and print/graphic arts, facilitating cost-effective and environmentally sustainable solvent reuse across various industries.

Industrial Cleaning

Solvent recyclers play a crucial role in industrial cleaning processes by efficiently recovering and reconditioning solvents used in degreasing, parts cleaning, and other manufacturing applications. This not only reduces waste but also lowers operational costs associated with solvent procurement.

Paint and Coating Operations

In the realm of paint and coating applications, solvent recyclers contribute to sustainable practices by reclaiming used solvents from cleaning equipment, spray guns, and paint booths. This enables businesses to maintain high-quality coating processes while minimizing the environmental impact of solvent disposal.

Laboratory and Research Facilities

Solvent recyclers find extensive use in laboratories and research facilities where various solvents are employed for analytical and experimental purposes. These devices help laboratories adhere to environmental regulations by recovering and purifying solvents, promoting a more eco-friendly approach to scientific research.

Print and Graphic Arts

In the print and graphic arts industry, solvent recyclers are employed to recover solvents used in printing processes, such as ink cleaning and plate preparation. By reusing solvents, businesses in this sector can enhance cost-effectiveness and reduce the overall environmental footprint associated with solvent waste disposal.

Solvent Recycler Related Products

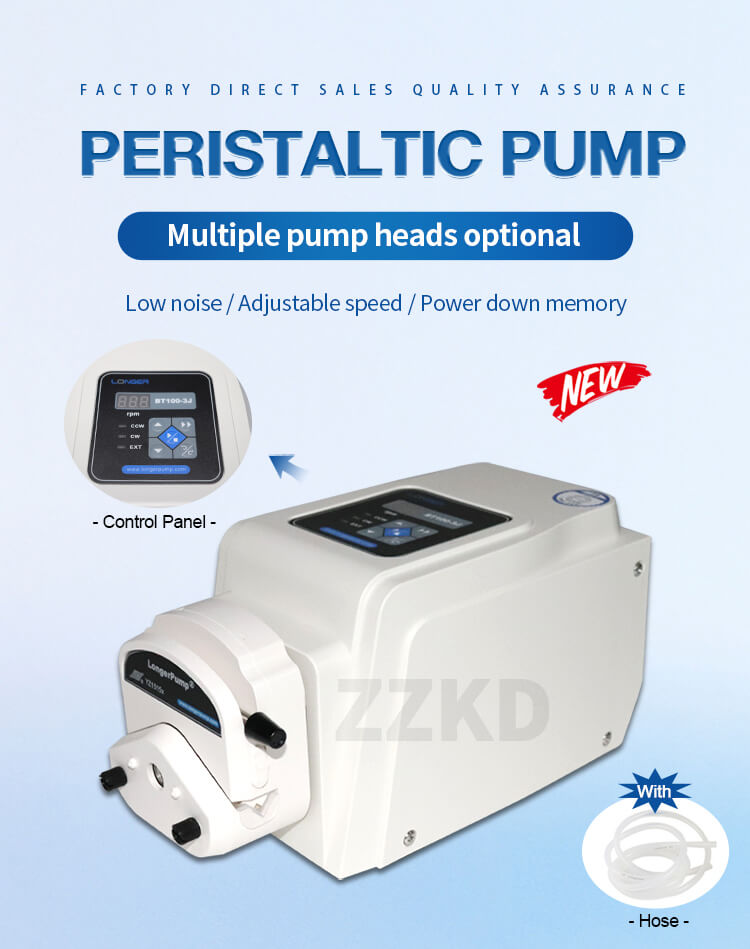

Peristaltic pumps are valued for their reliability, precision, and the ability to handle a diverse range of fluids, making them a popular choice in numerous industries and applications.

Peristaltic Pump

A peristaltic pump is a type of positive displacement pump used for the precise and controlled transfer of fluids. It operates on the principle of peristalsis, mimicking the natural rhythmic contractions and expansions of muscles in the human digestive system. The pump consists of a flexible tube or hose placed inside a circular pump casing with rollers or shoes that compress and decompress the tube, creating a series of vacuum draws and pressure pushes.

Peristaltic Pump Applications:

1. Laboratory and Research: Widely used in laboratories for accurate dosing and transferring of chemicals, reagents, and biological fluids in analytical instruments, chromatography, and other research applications.

2. Medical and Pharmaceutical: Commonly employed for drug infusion, intravenous therapy, and other medical applications where precise fluid delivery is critical.

3. Industrial Processes: Suitable for transferring various fluids in industrial processes such as chemical manufacturing, food and beverage production, and wastewater treatment.

4. Biotechnology: Used in bioprocessing and fermentation for the transfer of sensitive and shear-sensitive fluids in the production of pharmaceuticals and bio-based products.

5. Water Treatment: Applied in water treatment systems for metering chemicals like disinfectants and pH adjusters.

What is a solvent recycler?

A solvent recycler is a sophisticated apparatus designed to address environmental and cost concerns associated with solvent usage in industrial processes. It employs advanced distillation techniques to purify and recover used solvents, ensuring they meet desired quality standards for reuse.

The recycler works by heating the contaminated solvent, causing it to evaporate. The vapor is then condensed back into liquid form, leaving impurities behind. This process effectively separates the contaminants from the solvent, allowing businesses to reclaim and recycle their solvents.

How does a solvent recycler work?

Solvent recyclers utilize a multi-step process to purify used solvents. First, the contaminated solvent undergoes heating, causing it to vaporize. The vapor is then condensed, converting it back into a liquid state. This distilled liquid is free from impurities, making it suitable for reuse in various industrial applications.

The recycler’s distillation process is carefully controlled, ensuring that only the pure solvent is collected. The result is a high-quality, reclaimed solvent that meets or exceeds industry standards, providing a sustainable and cost-effective solution for businesses.

What types of solvents can be recycled?

Solvent recyclers are versatile and can effectively handle a wide range of solvents commonly used in industrial processes. Whether it’s acetone, isopropyl alcohol, or other industrial solvents, the recycler’s distillation process is designed to separate contaminants from various solvent types, enabling their efficient recovery and reuse.

This versatility makes solvent recyclers adaptable to diverse industries, accommodating the specific solvent requirements of businesses engaged in manufacturing, pharmaceuticals, printing, and other sectors.

Is solvent recycling cost-effective?

Yes, solvent recycling is a highly cost-effective solution for businesses dealing with significant solvent consumption. While there is an initial investment in acquiring a solvent recycler, the long-term savings are substantial. The ability to reclaim and reuse solvents significantly reduces the need for purchasing new ones, leading to reduced procurement costs and waste disposal fees.

Additionally, by minimizing the environmental impact of solvent disposal and reducing the carbon footprint associated with solvent production, businesses adopting solvent recyclers contribute to sustainability efforts, further enhancing their cost-effectiveness in the broader context.

Can a solvent recycler handle hazardous waste?

Yes, many solvent recyclers are specifically designed to handle hazardous waste generated from industrial processes. They comply with stringent environmental regulations, ensuring the safe and legal disposal of contaminated solvents. This capability is crucial for businesses operating in sectors where the use of hazardous solvents is common.

By employing a solvent recycler, businesses not only reduce the risk of environmental harm but also demonstrate a commitment to responsible waste management practices, aligning with regulatory requirements and ethical standards.

How much solvent can be recycled at once?

The capacity of solvent recyclers varies, with models available to suit different production scales. While smaller units may process several gallons per cycle, larger industrial-grade recyclers can handle substantial volumes in a single distillation cycle. This scalability ensures that businesses of varying sizes can benefit from solvent recycling, making the process efficient and adaptable to their specific needs.

The ability to process significant quantities in each cycle contributes to the overall efficiency of solvent recycling, making it a practical and viable solution for businesses with varying solvent consumption rates.

Are solvent recyclers environmentally friendly?

Absolutely. Solvent recyclers play a pivotal role in promoting environmental sustainability by reducing the environmental impact associated with solvent usage. The recycling process minimizes the volume of hazardous waste generated, decreases the demand for new solvent production, and helps businesses achieve their sustainability goals.

Additionally, the reduction in waste disposal requirements and the overall environmental footprint associated with solvent disposal contribute to a more eco-friendly industrial landscape. Solvent recyclers are, therefore, integral to environmentally conscious business practices.

What safety features do solvent recyclers have?

Solvent recyclers are equipped with a range of safety features to ensure the secure operation of the equipment. Common safety features include automatic shut-off mechanisms, pressure release valves, and temperature controls. These features are designed to prevent overheating, pressure buildup, and other potential hazards during the solvent distillation process.

Manufacturers prioritize the safety of users and the integrity of the recycling process, incorporating advanced safety features that adhere to industry standards. As a result, businesses can confidently operate solvent recyclers, knowing that these safety measures are in place to protect both personnel and equipment.

Can solvents be recycled multiple times?

Yes, solvents can undergo multiple recycling cycles without a significant decline in quality. The distillation process employed by solvent recyclers effectively separates contaminants during each cycle, ensuring that the reclaimed solvent maintains the desired purity levels for reuse.

The ability to recycle solvents multiple times enhances the overall sustainability and cost-effectiveness of solvent recycling. Businesses can derive extended value from their initial investment in a solvent recycler by repeatedly reclaiming and reusing solvents, reducing the frequency of new solvent purchases and waste disposal.

How long does the solvent recycling process take?

The duration of the solvent recycling process varies depending on factors such as the recycler’s capacity, the type of solvent being processed, and the desired level of purification. While smaller units may complete a cycle in a few hours, larger industrial-scale recyclers may take longer to process substantial volumes.

It’s important to note that the efficiency and speed of solvent recycling equipment have improved over time, with some advanced models offering quicker turnaround times. Businesses can choose a solvent recycler that aligns with their production timelines, ensuring a balance between efficiency and the desired level of solvent purity.

Is training required to operate a solvent recycler?

While solvent recyclers are designed to be user-friendly, basic training is recommended for operators to ensure safe and efficient use. Manufacturers typically provide comprehensive user manuals and training materials that cover essential aspects of operating the equipment.

Training may include instructions on loading and unloading solvents, routine maintenance procedures, and safety protocols. By investing time in training, businesses can empower their operators to use solvent recyclers effectively, maximizing the benefits of solvent recycling while minimizing the risk of errors or accidents.

Can a solvent recycler be customized for specific solvents?

Yes, many solvent recyclers offer customization options to cater to the unique solvent requirements of different industries. The distillation parameters can be adjusted to effectively handle specific solvents and contaminants commonly found in various industrial processes.

This customization capability ensures that businesses can tailor their solvent recycling approach based on the types of solvents used in their operations. Whether dealing with polar or non-polar solvents, customization options empower businesses to optimize the recycling process for maximum efficiency and effectiveness.

What is the maintenance required for a solvent recycler?

Solvent recyclers typically require routine maintenance to ensure optimal performance and longevity. Maintenance tasks may include cleaning components, replacing consumables such as filters or distillation columns, and inspecting safety features for proper functionality.

Regular maintenance not only extends the lifespan of the equipment but also contributes to consistent and reliable performance. Manufacturers provide detailed maintenance schedules and guidelines in user manuals, empowering businesses to proactively manage the upkeep of their solvent recyclers.

Are there any regulatory approvals for using solvent recyclers?

While specific regulations may vary by location, many solvent recyclers are designed to comply with industry standards and environmental regulations. Some models may even come with certifications, providing businesses with confidence that the equipment adheres to established guidelines for solvent recycling.

It’s essential for businesses to familiarize themselves with local regulations and obtain any necessary permits or approvals for using solvent recyclers. Adhering to regulatory requirements ensures legal compliance and reinforces the responsible use of solvent recycling technology.

Can a solvent recycler handle both polar and non-polar solvents?

Yes, the versatility of solvent recyclers extends to their ability to handle both polar and non-polar solvents. The distillation process is adaptable, effectively separating contaminants from a wide range of solvents commonly used in industrial applications.

This flexibility makes solvent recyclers suitable for businesses engaged in diverse industries, where different types of solvents are integral to their production processes. Whether dealing with water-based or organic solvents, a well-designed solvent recycler can accommodate various chemical compositions.

Does solvent recycling reduce waste disposal costs?

Absolutely. One of the primary benefits of solvent recycling is the substantial reduction in waste disposal costs for businesses. By reclaiming and reusing solvents, the volume of hazardous waste generated is significantly minimized, leading to cost savings associated with waste disposal fees and related compliance requirements.

Businesses adopting solvent recyclers not only contribute to their financial bottom line but also align with sustainable waste management practices. The reduced reliance on disposal services enhances the overall cost-effectiveness and environmental impact of their industrial operations.

Are there any industries where solvent recyclers are commonly used?

Solvent recyclers find widespread applications across various industries where solvents play a crucial role in production processes. Common sectors include manufacturing, pharmaceuticals, printing, automotive, and electronics manufacturing.

In these industries, where the use of solvents is integral to cleaning, degreasing, and other manufacturing processes, solvent recyclers provide a sustainable solution for managing solvent consumption. The versatility of solvent recyclers makes them valuable assets in industries with diverse solvent requirements.

Can a solvent recycler be integrated into existing workflows?

Yes, solvent recyclers are designed to seamlessly integrate into existing industrial workflows. They can be customized and positioned to fit the specific spatial and operational requirements of different production environments.

The adaptability of solvent recyclers ensures that businesses can incorporate the technology without disrupting their established processes. Whether as a standalone unit or integrated into a larger production line, solvent recyclers enhance efficiency and sustainability within existing workflows.

What is the energy consumption of a solvent recycler?

The energy consumption of solvent recyclers varies among different models. However, modern solvent recyclers are designed with energy efficiency in mind. Some models may incorporate features such as automatic shut-off when not in use or energy-saving modes during operation.

Manufacturers prioritize energy-efficient design to minimize operational costs and environmental impact. Businesses can select solvent recyclers that align with their sustainability goals, considering factors such as energy consumption and overall environmental footprint.

Can solvent recyclers be used for laboratory applications?

Yes, many solvent recyclers are suitable for laboratory use, providing an efficient and cost-effective solution for recycling solvents in research and analytical processes. These compact and versatile units cater to the specific needs of laboratories, enabling them to reclaim and reuse solvents while maintaining the required purity levels.

Laboratories benefit from the cost savings and sustainability advantages of solvent recycling, aligning with the broader trend of responsible solvent management in scientific and research environments. Solvent recyclers for laboratory applications contribute to both operational efficiency and environmental responsibility.

SOLVENT RECYCLER

Ce Certified Solvent Recycler Manufacturer

- Famous Brand Accessories

- More Than 33 Years of Manufacturing Experience

- Affordable Solvent Recycler Price

- Experienced Customer Service