Paint Solvent Recovery System Introduction

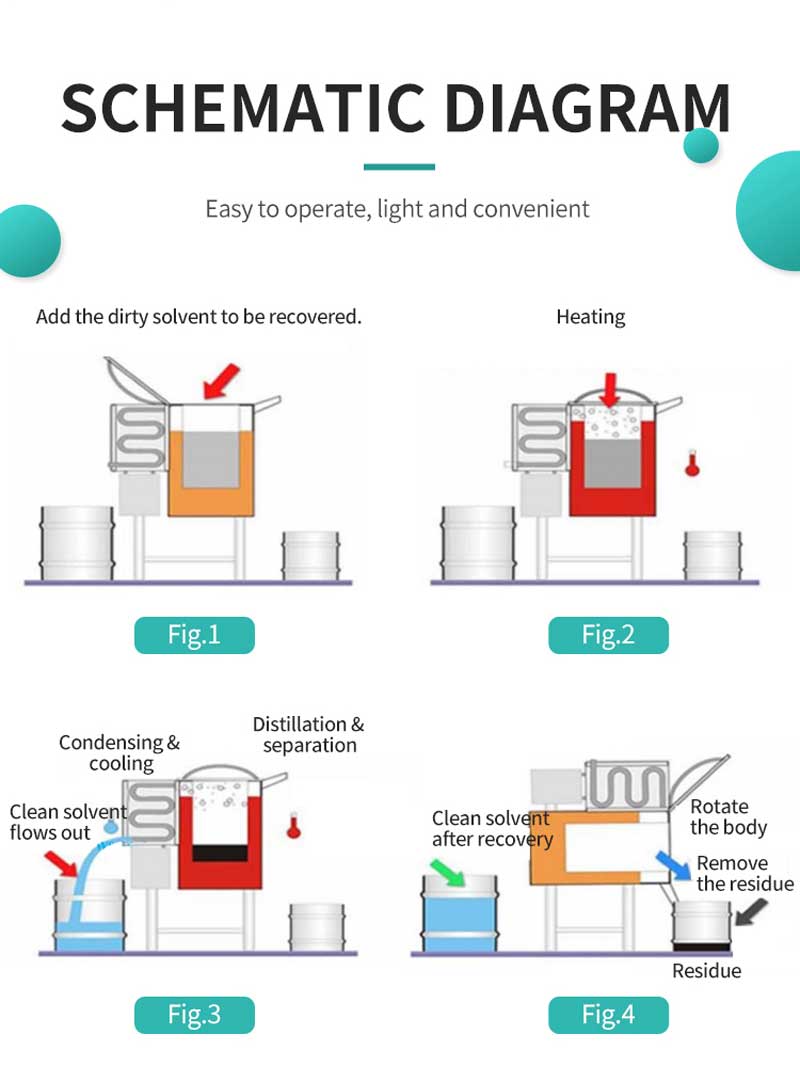

T-100Ex paint solvent recovery system, using the distillation principle, is an explosion-proof structure. The solvent is evaporated by heating and becomes a gaseous state. By recycling solvents, businesses can significantly reduce their solvent consumption and waste disposal costs, making it a cost-effective solution for businesses of all sizes.

Paint Solvent Recovery System Features:

- Designed with European and American safety standards (atex) and national explosion-proof standards (cnex), fully explosion-proof structure.

- Independent research and development, standardized mass production, guaranteed quality.

- Air-cooled model, good environmental adaptability, not afraid of cold weather.

- Pourable structure, easy to clean residue.

- Timing, constant temperature shutdown, high temperature, high pressure, power failure protection and other multiple protection functions, worry-free and safe use.

- Single-stage/double-stage temperature control, external digital display, precise temperature control, convenient operation, can recover single solvent or mixed solvent in stages.

- Recycling bin made of stainless steel, corrosion-resistant; indirect heating with double-layer structure, safe heating.

- All cable joints are explosion-proof sealed design, stainless steel hose protection, anti-corrosion, safe.

- The recovered solvent is of high quality, clear and pure, with good color and good performance.

- The recycling process is short and the operation is simple. Ordinary employees can go to work safely on the same day of training.

- Stable and durable performance, simple maintenance, less consumables, and ultra-low maintenance costs.

Paint Solvent Recovery System Application:

- Electronic product manufacturing industry (such as: lcd, led, etc.):

Cleaning agents for cleaning molds and cleaning electronic products themselves, such as absolute ethanol, acetone, trichlorethylene, etc.

- Manufacturing of precision instruments and hardware:

Organic solvents for cleaning molds and processed products, such as thinner, hydrocarbons, kerosene, solvent gasoline, etc.

- Sports equipment manufacturing industry:

Cleaning agent for wax-melted castings such as golf heads and fishing rods, and solvent for spraying and cleaning clubs and fishing rods.

4.frp product industry:

Solvents used in surface anti-corrosion and aesthetic coating production processes, such as: yacht production, wind turbine blade production, etc.

- Painted gold jewelry industry:

Solvents used for surface pretreatment cleaning and pre-plating treatment.

- Optical products:

Solvents used in cleaning and pre-coating treatment of components in each production process.

- Furniture manufacturing industry:

Organic solvents for cleaning spraying equipment and paint mixing, such as thinner, xylene, methyl ethyl ketone, acetone, etc.]

Operation Precautions:

- Any fireworks are strictly prohibited, keep away from fire sources

- Well ventilated, install exhaust equipment

- The temperature should not be too high, no direct sunlight

- Switches, power plugs and sockets must be explosion-proof

- Please wear a protective mask

- Please wear protective glasses

- Please wear protective gloves

- The power switch must be set outdoors

- When recycling, it is strictly forbidden to dump the chassis! After recycling, before dumping the chassis, the air release valve should be tightened to avoid leakage of hot kerosene.

- Do not remove or modify any parts of the recycling machine, especially the protection network!!

- Do not perform recovery distillation until you fully understand the composition of solvents and related wastes.

Benefits of buying zzkd paint solvent recovery system

We can solve problems that other paint solvent recovery systems cannot solve

- The cooling system adopts air cooling to dissipate heat;

- Dumping function, convenient to clean up the residue after recycling;

- Unique segmental recovery function to solve the foaming problem of mixed solvents;

- Equipped with corresponding calstar condensers, low boiling point solvents from -25°C to 60°C can be recovered;

- Equipped with corresponding calstar vacuum pump, it can recover high boiling point solvent below 300℃;

- Adopt four-point support, the equipment is stable and safe.

ZZKD paint solvent recovery system influence brand

(1). Obtained the product safety certification of the National Electrical Safety Explosion-proof Center: the product structure design and product manufacturing have been certified by the authority. The explosion-proof safety design of the whole machine and equipment components meets the national safety standards for explosion-proof electrical products, allowing you to use it worry-free and safe.

(2). The machine has good quality and stable performance: independent research and development, standardized mass production, and guaranteed quality.

(3). The machine has a wide range of applications: it can recycle common organic solvents in various industries.

(4). The recycling process is simple and the machine operation is convenient: ordinary employees can work safely after short-term training.

(5). Ultra-low machine maintenance cost: the machine performance is stable, durable, easy to maintain, and less consumables.

(6). The recovered solvent is of high quality: the recovered solvent is positive in color, clear, pure and of good performance.