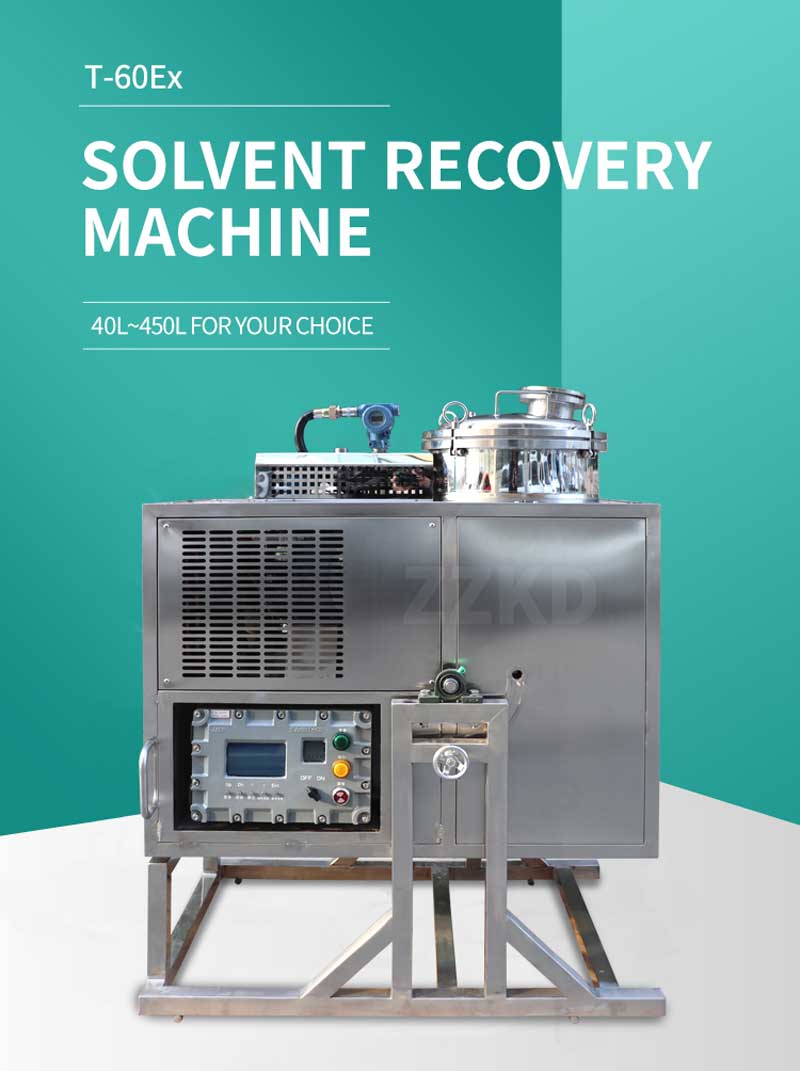

Solvent Recycler Machine Introduction

T-60Ex solvent recycler machine utilizes advanced distillation processes to recover up to 99% of solvents used in industrial processes. By recycling solvents, businesses can significantly reduce their solvent consumption and waste disposal costs, making it a cost-effective solution for businesses of all sizes.

Solvent Recycler Machine Features:

Explosion-proof design:

Our T-60Ex Solvent Recycler Machine is designed to meet the strict requirements for hazardous areas and is explosion-proof, ensuring safe operation in environments where explosive materials are present.

High-quality and pure recovered solvents:

Our machine is designed to be efficient, ensuring that recovered solvents are of high quality and purity, making them suitable for immediate reuse in various industrial processes.

Cost-effective:

By recycling solvents, businesses can significantly reduce their solvent consumption and waste disposal costs, making it a cost-effective solution for businesses of all sizes.

Eco-friendly:

Our Solvent Recycler Machine is an eco-friendly alternative to traditional solvent disposal methods, helping businesses reduce their carbon footprint and comply with environmental regulations.

Easy to use:

Our machine is designed to be user-friendly, with an intuitive interface that allows for easy operation and maintenance.

Compact design:

Our T-60Ex Solvent Recycler Machine is compact and space-saving, making it suitable for businesses of all sizes, from small-scale operations to large industrial facilities.

Solvent Recycler Machine Application:

Paint and coating industry:

Our machine can effectively recover solvents used in the manufacturing of paints, coatings, and varnishes, reducing waste and disposal costs for businesses.

Printing industry:

Our machine can recover solvents used in the printing process, allowing businesses to reuse them and reduce their solvent consumption and disposal costs.

Pharmaceutical industry:

Our machine can recover solvents used in the manufacturing of pharmaceutical products, reducing waste and disposal costs for businesses.

Automotive industry:

Our machine can recover solvents used in the manufacturing of automotive parts and components, reducing waste and disposal costs for businesses.

Aerospace industry:

Our machine can recover solvents used in the aerospace industry for cleaning and other industrial processes, reducing waste and disposal costs for businesses.

Electronics industry:

Our machine can recover solvents used in the manufacturing of electronic components, reducing waste and disposal costs for businesses.

Working principle of Solvent Recycler Machine:

Collection:

The used solvent is collected and stored in a collection tank.

Pre-treatment:

The solvent is filtered and treated to remove any large contaminants or impurities.

Distillation:

The solvent is then heated in a distillation chamber, causing it to vaporize and separate from any remaining contaminants or impurities.

Condensation:

The vaporized solvent is then condensed and cooled back into a liquid form by a condenser, which removes any remaining impurities and contaminants from the solvent.

Recycle:

The purified solvent is collected in a separate container, while the remaining contaminants and impurities are disposed of as hazardous waste.

Case Of Solvent Recycler Machine:

Spraying paint in the furniture and showcase industry can make the product more beautiful and bright, improve the rough feel of the product itself, and make the furniture not affected by climate and dry and wet changes. It not only protects and maintains wood and bamboo furniture, but also makes the whole family life Get more comfortable! While painting brings us color, texture and enjoyment of life, a large amount of waste solvents will be generated in the painting operation, such as toluene, xylene, thinner, acetone, gun cleaner, thinner, banana water and other organic solvents waste liquid. The recycling and reuse of waste solvents can not only greatly save the cost of purchasing new solvents, but also reduce the cost of waste solvent treatment and reduce the pollution and damage of waste solvents to the environment. It is a good way to serve multiple purposes.

A furniture company produces about 60 kilograms of waste gun cleaning water every day. In June 2015, it began to use Yitai gun cleaning water recycling machine for recycling. More than 50 kilograms of waste gun cleaning water are recycled every day, and waste gun cleaning water is recycled The rate is between 90-95%, which saves the company about 500 yuan in the purchase cost of new solvents every day.

Customer comments: I am very grateful to ZZKD for recommending their company’s solvent recovery machine to me. Before using the solvent recovery machine, the waste solvents had to be disposed of by an environmental protection company at a cost, and there was usually no place to store the waste solvents in large quantities. The higher-ups inspected and said that the waste solvents were piled up randomly, but I couldn’t find a place to put them. After using the ZZKD solvent recovery machine, the waste solvent can be recovered in time and then used to clean the spray guns, fixtures, etc., which not only solves the problem of no place for waste solvent to be piled up, but also saves a lot of waste solvent treatment costs for the company. and new solvent purchase costs. The solvent recovery machine has really helped me a lot.