Solvent reclaimer machine have revolutionized various industries, including the chemical and pharmaceutical sectors. These innovative devices play a crucial role in recycling solvents, reducing waste, and improving overall operational efficiency. In this section, we’ll delve into the fundamental concepts of solvent reclaimer machines and how they benefit modern industrial processes.

1. Understanding Solvent Reclaimer Machines

Solvent reclaimer machines are specialized equipment designed to recover and purify solvents used in various industrial processes. These processes often generate a significant amount of solvent waste, which can be costly and environmentally damaging to dispose of. Solvent reclaimer machines address this issue by efficiently separating and distilling solvents, allowing them to be reused in the production process.

The Importance of Solvent Reclamation

Solvent reclaimer machines are a sustainable solution to the problem of solvent waste disposal. They not only reduce the environmental impact but also offer substantial cost savings for businesses. By recovering and recycling solvents, companies can minimize their expenses associated with purchasing new solvents and disposing of hazardous waste.

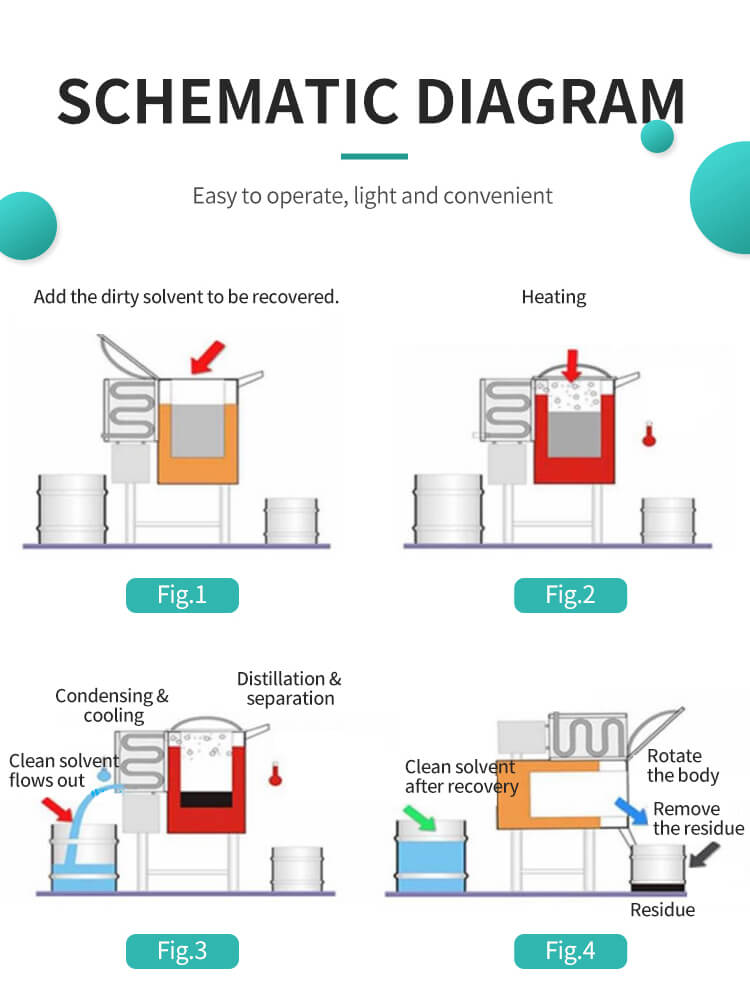

How Solvent Reclaimer Machines Work

These machines operate on the principle of distillation. They heat the solvent waste, causing it to evaporate. The vapor is then condensed and collected, leaving behind contaminants and impurities. The purified solvent can be reused in industrial processes, while the waste residue can be safely disposed of.

Types of Solvent Reclaimer Machines

There are several types of solvent reclaimer machines available, each catering to specific industrial needs. Some are designed for batch processing, while others offer continuous solvent reclamation. The choice of machine depends on factors like the volume of solvent waste generated and the nature of the solvents used in the process.

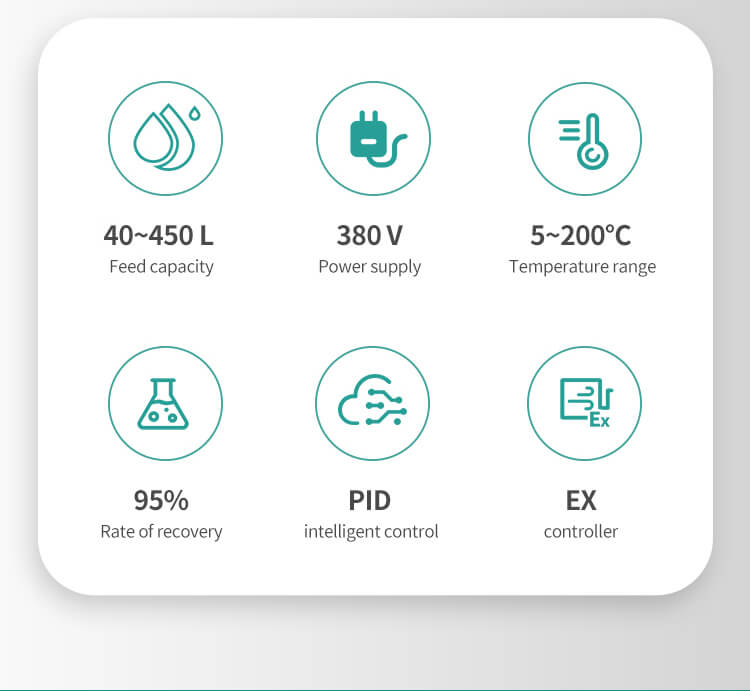

2. Key Features of Solvent Reclaimer Machines

When considering the purchase of a solvent reclaimer machine, it’s essential to understand the key features that make these devices efficient and reliable. In this section, we’ll explore some of the critical features to look for in solvent reclaimer machines.

Automatic Solvent Monitoring

Many modern solvent reclaimer machines come equipped with automatic monitoring systems that ensure the solvent reclamation process runs smoothly. These systems can detect variations in solvent quality and adjust the settings accordingly, maximizing efficiency.

Safety Measures

Safety is paramount in industrial settings, and solvent reclaimer machines are no exception. Look for machines that have robust safety features, such as pressure and temperature monitoring, to prevent accidents and ensure operator well-being.

Energy Efficiency

Efficient energy consumption is vital for reducing operational costs. Solvent reclaimer machines should be designed to minimize energy usage while maintaining high performance. Energy-efficient machines not only save money but also reduce their environmental footprint.

3. Applications of Solvent Reclaimer Machines

Solvent reclaimer machines find applications in various industries, thanks to their versatility and effectiveness. In this section, we’ll explore some of the primary industries that benefit from the use of solvent reclaimer machines.

Chemical Industry

In the chemical industry, solvent reclaimer machines play a pivotal role in recovering and recycling solvents used in the production of various chemicals. This not only reduces waste but also ensures a more sustainable and cost-effective manufacturing process.

Pharmaceutical Industry

Pharmaceutical companies rely on highly pure solvents for drug manufacturing. Solvent reclaimer machines help maintain the quality and purity of solvents, complying with stringent regulatory standards while minimizing production costs.

Printing and Coating Industry

In the printing and coating industry, solvents are used extensively. Solvent reclaimer machines allow these businesses to recover solvents, making their operations more environmentally friendly and cost-efficient.

4. Benefits of Using Solvent Reclaimer Machines

Using solvent reclaimer machines offers numerous advantages for businesses across various industries. Let’s explore some of the key benefits associated with these innovative devices.

Cost Savings

One of the most significant benefits of using solvent reclaimer machines is the potential for substantial cost savings. By recycling solvents, companies can significantly reduce their expenses related to solvent procurement and disposal.

Environmental Sustainability

Solvent reclaimer machines contribute to a more sustainable future by reducing solvent waste and minimizing the environmental impact of industrial processes. This aligns with the growing global emphasis on eco-friendly practices.

Improved Product Quality

Reclaimed solvents are often of high quality, ensuring that the final products meet industry standards and customer expectations. This is particularly crucial in industries like pharmaceuticals and electronics manufacturing, where product quality is paramount.

5. Choosing the Right Solvent Reclaimer Machine

Selecting the appropriate solvent reclaimer machine for your specific needs is crucial. In this section, we’ll provide guidance on how to make an informed decision when purchasing a solvent reclaimer machine.

Assessing Your Requirements

Begin by assessing your solvent usage and waste generation. Determine the volume and types of solvents you need to reclaim, as this will influence the machine’s capacity and specifications you require.

Budget Considerations

Consider your budget and the long-term cost savings associated with solvent reclamation. While more advanced machines may have a higher initial cost, they often offer better efficiency and lower operational expenses in the long run.

Maintenance and Support

Lastly, inquire about maintenance requirements and the availability of technical support. Regular maintenance ensures the machine’s longevity and continued performance, and responsive support is essential for addressing any issues that may arise.

In conclusion, solvent reclaimer machines are indispensable tools for industries seeking to reduce waste, cut costs, and promote sustainability. By understanding their operation, features, applications, benefits, and how to choose the right machine, businesses can make informed decisions that enhance their operations and contribute to a greener future.