Glycol recycling, specifically ethylene glycol recycling, is becoming increasingly important in industries that use antifreeze and coolant solutions. Ethylene glycol is widely used in automotive, HVAC, and industrial cooling systems. Instead of disposing of used glycol, modern technology allows it to be purified and reused, significantly reducing both costs and environmental impact.

According to the U.S. Environmental Protection Agency (EPA), millions of gallons of used antifreeze are discarded each year, much of it containing heavy metals and other contaminants. Recycling prevents these harmful substances from entering the environment and allows industries to recover valuable raw materials.

What is Glycol Recycling?

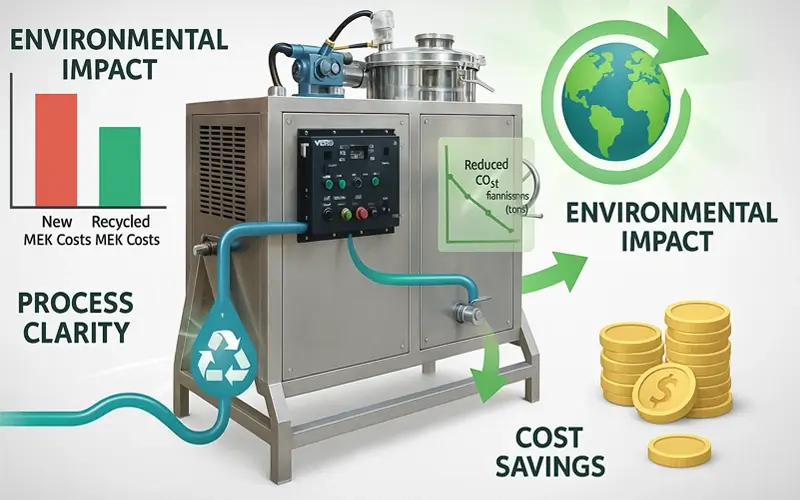

Glycol recycling is the process of cleaning and reprocessing used ethylene glycol so that it can be reused in its original applications. This is typically done using a solvent recovery machine, which employs distillation or filtration to remove contaminants.

Question: Why not just buy new glycol instead of recycling it?

Answer: New glycol production consumes significant energy and resources, and buying it repeatedly increases operational costs. Recycling can reduce costs by up to 80% while minimizing environmental harm.

How Does a Solvent Recovery Machine Work for Glycol?

A solvent distillation unit works by heating the used glycol until it evaporates, leaving contaminants behind. The vapor is then condensed back into liquid form, resulting in purified glycol that meets industry standards for reuse.

- Heating and evaporation separate glycol from impurities.

- Condensation recovers pure glycol.

- Residue waste is minimized and easier to dispose of.

According to a study by the Massachusetts Institute of Technology (MIT), technological innovations like advanced solvent recovery could reduce industrial chemical waste by up to 40% by 2030.

Environmental Benefits of Glycol Recycling

Recycling glycol greatly reduces the environmental footprint of industries. It prevents toxic runoff into water systems, lowers greenhouse gas emissions associated with manufacturing new glycol, and supports a circular economy.

Can recycled glycol match the quality of new glycol?

Yes. When processed with high-quality solvent recovery equipment, recycled glycol can meet or exceed ASTM standards for purity and performance.

Economic Advantages

For businesses, the economic benefits are clear. Recycling reduces the need to purchase new glycol, cuts waste disposal fees, and can even turn waste into a revenue stream if the recovered glycol is sold.

For example, a mid-sized automotive service center can save thousands of dollars annually by implementing a solvent recycler machine for antifreeze recovery.

Industries that Benefit from Glycol Recycling

| Industry | Application | Benefit of Recycling |

|---|---|---|

| Automotive | Antifreeze reuse | Lower operating costs |

| HVAC | Cooling system fluids | Reduced environmental impact |

| Manufacturing | Process cooling | Waste minimization |

Conclusion

Glycol recycling is not just an eco-friendly choice—it’s a smart business decision. With the help of modern solvent recovery equipment, industries can significantly reduce costs, comply with environmental regulations, and contribute to sustainable practices.

As environmental regulations tighten and raw material prices rise, adopting glycol recycling technology will become a necessity rather than an option.