In the ever-evolving landscape of industrial processes, efficiency and sustainability have become paramount. One crucial aspect of this transformation is solvent recovery distillation units. These innovative systems are at the forefront of revolutionizing various industries, providing a sustainable solution to recover valuable solvents. In this blog news, we’ll delve into the world of solvent recycler machine, exploring their significance, applications, and the environmental benefits they bring.

Understanding Solvent Recovery Distillation Units

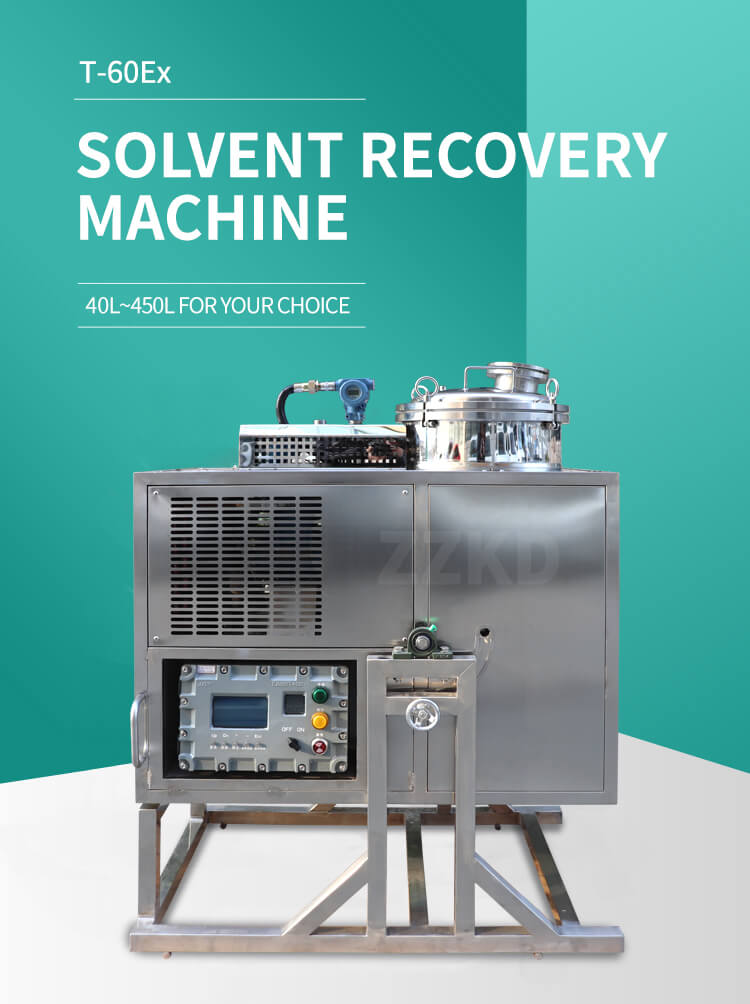

Solvent recovery distillation units are sophisticated pieces of equipment designed to separate and reclaim solvents from process waste streams. They employ the principles of distillation to achieve this, ensuring that solvents can be recovered and reused, reducing waste and cutting costs. These units are engineered with precision, offering a versatile solution to industries where solvents are a critical component.

The process is straightforward but highly effective. It begins with the collection of the solvent-laden waste, which is then heated in the distillation unit. As the temperature rises, the solvent evaporates, leaving behind impurities and contaminants. The solvent vapor is condensed and collected, ready for reuse, while the waste material is left as residue. This fundamental process is integral to a range of applications.

Applications Across Diverse Industries

Solvent recovery distillation unit find applications across various industries. They play a pivotal role in ensuring sustainability, cost-effectiveness, and improved environmental performance. Some key sectors where these units are making a significant impact include:

1. Pharmaceutical and Biotechnology

In the pharmaceutical and biotechnology industry, solvents are essential for various processes, including extraction and purification. Solvent recovery distillation unit help reduce waste, lower production costs, and support green initiatives.

2. Chemical Manufacturing

Chemical manufacturing relies heavily on solvents. By implementing solvent recovery distillation units, companies can optimize their operations, minimize environmental impact, and improve their bottom line.

3. Oil and Petrochemical

Solvents are utilized extensively in the oil and petrochemical sector. Recovery units help reduce solvent procurement costs, enhance safety, and minimize waste disposal concerns.

4. Food and Beverage

Even in the food and beverage industry, solvents play a role in processes like extraction and flavoring. Solvent recovery units ensure the efficient use of resources and reduce the environmental footprint.

Environmental Benefits of Solvent Recovery Distillation Units

One of the most compelling aspects of solvent recovery distillation unit is their positive impact on the environment. By embracing these units, industries can significantly reduce their carbon footprint and overall environmental impact. Here are some key environmental benefits:

1. Waste Reduction

The primary environmental benefit of solvent recovery is waste reduction. By reusing solvents, industries produce less hazardous waste that would otherwise need costly disposal.

2. Energy Efficiency

Solvent recovery units are designed for energy efficiency. They minimize energy consumption compared to traditional methods of solvent procurement, benefiting both the environment and the bottom line.

3. Lower Emissions

With reduced waste and efficient energy usage, solvent recovery distillation units help industries lower their emissions, contributing to a cleaner and more sustainable world.

The Future of Sustainable Industrial Practices

As industries worldwide continue to seek sustainable and efficient practices, solvent recovery distillation units have emerged as a game-changer. They not only optimize processes but also align with global environmental goals. By reducing waste, conserving resources, and cutting costs, these units are poised to lead the way toward a greener, more sustainable future for industrial processes.

Solvent recovery distillation units are a testament to innovation and environmental responsibility, offering a brighter and cleaner future for industries and the planet alike. Their integration into various sectors heralds a new era where sustainable industrial practices are not just an aspiration but a tangible reality.