Spray drying is a widely used industrial process that transforms a liquid feed into a dry powder in a matter of seconds. This technology plays a crucial role in industries such as food, pharmaceuticals, chemicals, and materials science. In simple terms, the spray drying process involves atomizing a liquid into fine droplets, which are then rapidly dried using hot air. The result is a free-flowing powder with specific particle size and moisture content.

According to a report by MarketsandMarkets, the global spray drying equipment market is projected to reach USD 6.5 billion by 2027, driven by the demand for instant foods, powdered pharmaceuticals, and advanced materials. This growth is supported by innovations in spray dryer design, such as energy-efficient heating systems and precise temperature control.

How the Spray Drying Process Works

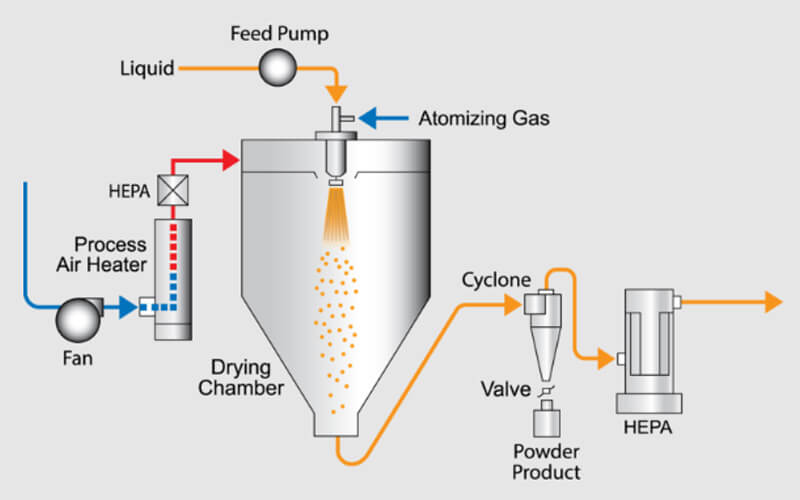

The spray drying process typically consists of four main stages:

- Atomization: The liquid feed is converted into a fine mist using a nozzle or rotary atomizer.

- Drying: The droplets are exposed to a stream of hot air, causing rapid evaporation of moisture.

- Particle Formation: As water evaporates, solid particles form and settle.

- Collection: The dried powder is separated from the air stream using cyclones or bag filters.

Question: Why is spray drying preferred over other drying methods for heat-sensitive materials?

Answer: Spray drying offers extremely rapid moisture removal, which minimizes the time materials are exposed to heat. This makes it ideal for products like milk powder, pharmaceuticals, and probiotics, where excessive heat could damage nutrients or active compounds.

Applications of Spray Drying

Spray drying is used in a variety of industries:

- Food Industry: Milk powder, coffee, flavorings, and nutritional supplements.

- Pharmaceuticals: Antibiotics, enzymes, and inhalable powders.

- Chemicals: Detergents, catalysts, and ceramics.

- Biotechnology: Preservation of probiotics and enzymes.

For smaller-scale research and development, devices like the mini spray dryer are popular in laboratories due to their compact size and ease of use.

Question: Can spray drying be integrated with other processes for better efficiency?

Answer: Yes. Spray drying can be combined with processes like solvent distillation or freeze drying to improve product stability and purity, especially in pharmaceutical and chemical applications.

Advantages and Limitations

| Advantages | Limitations |

|---|---|

| Rapid drying suitable for heat-sensitive products | High energy consumption |

| Uniform particle size distribution | Requires pre-treatment of feed |

| Scalable from lab to industrial production | Equipment cost can be high |

Future Trends in Spray Drying

With the rise of Industry 4.0, modern spray dryers are being equipped with AI-based monitoring systems. According to a study by the Massachusetts Institute of Technology (MIT), AI is expected to automate up to 30% of manufacturing processes by 2030, which includes quality control in spray drying systems.

Compact systems like the small freeze dryer are also being adapted for hybrid drying methods, combining spray drying and freeze drying for products that require both speed and preservation of delicate compounds.