A borosilicate glass reactor is one of the most common and versatile pieces of equipment in chemical and pharmaceutical laboratories. From synthesis and crystallization to distillation and scale‑up, glass reactors offer rare visibility into what is happening inside a reaction — while handling a wide range of solvents, acids, and process conditions.

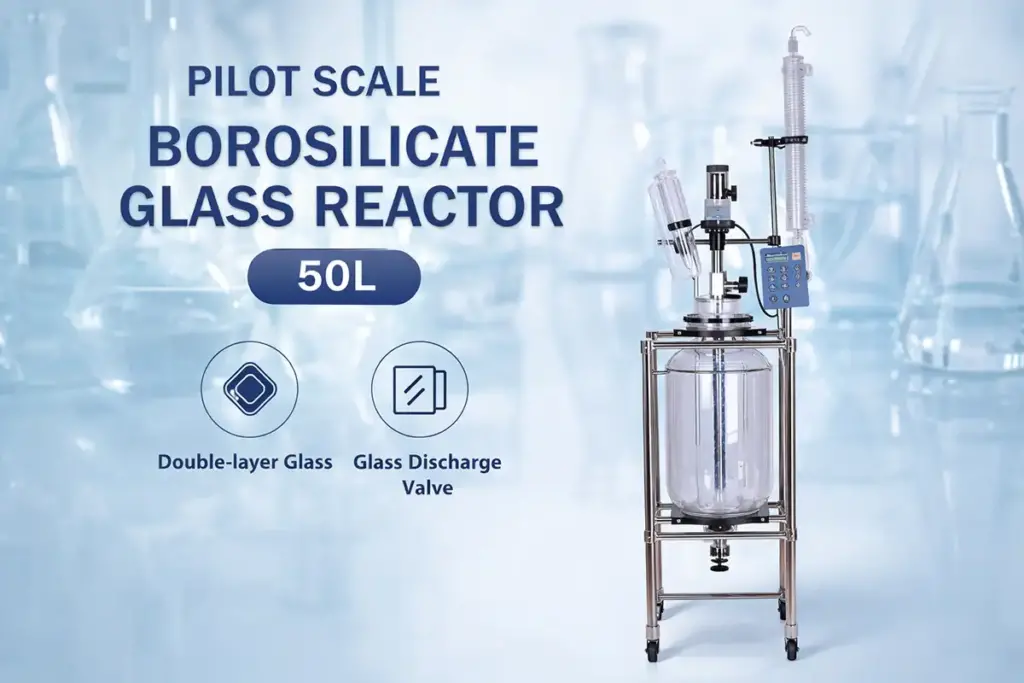

Typical jacketed borosilicate glass reactor with overhead stirring and support frame.

1. What Is a Borosilicate Glass Reactor?

A borosilicate glass reactor is a reaction vessel made from borosilicate glass, a special glass containing silica and boron trioxide. This composition makes the material highly resistant to:

- Thermal shock (fast heating and cooling)

- Chemical corrosion from most acids and organic solvents

- Surface cracking under typical lab conditions

In practice, the reactor is usually a jacketed glass vessel mounted on a metal frame and equipped with:

- Mechanical stirrer and variable‑speed motor

- Temperature probe and ports for dosing, reflux, or vacuum

- Jacket connection for a circulating chiller or heater

Evidence‑based design

Why borosilicate, not ordinary glass?

According to data from the German Institute for Standardization (DIN 12111), typical borosilicate 3.3 glass has a linear thermal expansion coefficient of about 3.3 × 10⁻⁶ K⁻¹. That is roughly one third that of conventional soda‑lime glass, which is why borosilicate can withstand rapid temperature changes and repeated heating–cooling cycles with much lower risk of cracking.

2. Why Choose a Borosilicate Glass Reactor?

Compared with stainless steel or PTFE vessels, a borosilicate glass reactor offers several clear advantages for lab and pilot‑scale work:

- Full transparency – direct observation of mixing, phase separation, crystallization, and foaming.

- Excellent chemical resistance – compatible with most organic solvents and many acids.

- Smooth, non‑porous surface – reduces contamination and simplifies cleaning.

- Accurate temperature control – via a double‑layer jacket connected to a chiller or heater.

- Modularity – easy to connect with rotary evaporators, condensers, or distillation setups.

Could a borosilicate glass reactor replace all stainless steel reactors in a lab?

From my perspective, the answer is no. While borosilicate glass is ideal for ambient to moderate pressure and a broad temperature range (commonly about −80 °C to +200 °C, depending on design), it is not intended for very high pressure. For high‑pressure hydrogenation or supercritical reactions, a high pressure autoclave reactor in stainless steel is still the safer choice.

3. Key Specifications: From 1 L to 100 L

For most labs, the first questions are very practical: What volumes are available? and How much power does the motor need for proper stirring? Below is a simplified overview of two common series of double‑reactor systems, covering 1 L–5 L and 10 L–100 L.

3.1 Small‑scale Borosilicate Glass Reactor (1 L–5 L)

| Model | Reaction Kettle Capacity (L) | Stirring Power (W) | Stirring Speed (rpm) | Stirring Shaft Diameter (mm) | Motor Torque (g/cm) | Power Supply | Note |

|---|---|---|---|---|---|---|---|

| S-1L | 1 | 60 | 0–600 (Max. 1300) | 12 | 2000 | 220 V, 50/60 Hz | Floor type, explosion‑proof optional. Stirring power up to 180 / 250 / 370 W; 110 V / 60 Hz customizable. |

| S-2L | 2 | 60 | 0–600 (Max. 1300) | 12 | 2400 | 220 V, 50/60 Hz | |

| S-3L | 3 | 60 | 0–600 (Max. 1300) | 12 | 4800 | 220 V, 50/60 Hz | |

| S-5L | 5 | 60 | 0–600 (Max. 1300) | 12 | 4800 | 220 V, 50/60 Hz |

Tip: swipe horizontally on mobile to see all columns.

The 1–5 L series is typically used for method development, small‑batch synthesis, and reaction screening. A 60 W drive with up to 1300 rpm is sufficient for low‑ to medium‑viscosity liquids, especially when proper impeller design is used.

3.2 Bench‑top and Pilot Borosilicate Glass Reactor (10 L–100 L)

| Model | Reaction Kettle Capacity (L) | Stirring Power (W) | Stirring Speed (rpm) | Stirring Shaft Diameter (mm) | Motor Torque (g/cm) | Power Supply | Note |

|---|---|---|---|---|---|---|---|

| S-10L | 10 | 120 | 0–600 (Max. 1300) | 12 | 1000 | 220 V, 50/60 Hz | 304 stainless steel frame; explosion‑proof optional. Stirring power can be 180 / 250 / 370 W; 110 V / 60 Hz available. |

| S-20L | 20 | 250 | 0–600 (Max. 1300) | 15 | 1200 | 220 V, 50/60 Hz | |

| S-30L | 30 | 250 | 0–600 (Max. 1300) | 15 | 1500 | 220 V, 50/60 Hz | |

| S-50L | 50 | 250 | 0–600 (Max. 1300) | 15 | 3000 | 220 V, 50/60 Hz | |

| S-100L | 100 | 250 | 0–600 (Max. 1300) | 15 | 3000 | 220 V, 50/60 Hz |

Tip: swipe horizontally on mobile to see all columns.

For volumes from 10 L to 100 L, motor power and shaft diameter naturally increase, and the 304 stainless steel frame provides stability for taller glass vessels. Torque values up to 3000 g/cm help maintain effective mixing even as viscosity increases during polymerization or concentration.

Pilot‑scale borosilicate glass reactor, suitable for process scale‑up and small production.

4. How to Choose the Right Borosilicate Glass Reactor

Choosing a borosilicate glass reactor can be simple if a few key questions are answered clearly.

4.1 Define the Working Volume and Purpose

- 1–5 L: ideal for method development, route scouting, and small‑scale synthesis.

- 10–30 L: suitable for kilo‑lab, process optimization, crystallization studies.

- 50–100 L: used for pilot production, small batches, and scale‑up trials.

Is it better to buy one large 50 L borosilicate glass reactor instead of several smaller ones?

In my experience, the answer depends on the workload. For a research team with many parallel projects, multiple 5–20 L reactors often give more flexibility and higher overall throughput. A 50 L or 100 L reactor is more suitable when one process has already been fixed and must be scaled for pre‑production or pilot use.

4.2 Consider Stirring Speed, Torque, and Viscosity

All models listed provide 0–600 rpm (up to 1300 rpm maximum). This range covers:

- Gentle mixing for sensitive crystals and suspensions.

- Faster vortex mixing for liquid–liquid or gas–liquid systems.

Torque (1000–4800 g/cm depending on model) is equally important. Higher torque is needed for:

- High‑viscosity media (polymerization, concentration, slurries).

- High‑solids crystallization and crystallization under cooling.

4.3 Temperature and Safety Requirements

Many applications require operation under vacuum or use of flammable solvents. Several safety aspects should be checked:

- Explosion‑proof motor and control: recommended for large volumes or solvents with low flash points.

- Vacuum‑rated components: valves, seals, and joints must be rated for the target vacuum level.

- Reliable temperature control: a compatible chiller/heater loop with the jacket volume and temperature range.

Question: What is the typical working temperature range of a borosilicate glass reactor?

Answer (from an application perspective): For most borosilicate glass reactors, the recommended working range is approximately −80 °C to +200 °C when properly supported and heated/cooled gradually. The exact limits depend on wall thickness, reactor design, and the rate of temperature change, so manufacturer guidelines should always be followed.

5. Typical Applications of Borosilicate Glass Reactors

In modern labs and pilot plants, borosilicate glass reactors are widely used in:

- Organic synthesis – multi‑step reactions, coupling, and catalytic reactions.

- Crystallization and recrystallization – process development, API crystallization, and polymorph screening.

- Distillation and solvent recovery – when combined with condensers or a solvent distillation unit.

- Polymerization and material synthesis – resins, monomer polymerization, and material precursors.

- Teaching and demonstration – visualizing real‑time reaction behavior for students and trainees.

Transparent borosilicate glass makes crystallization and phase changes easy to observe.

Industry insights

A recent survey published by a European fine‑chemicals association noted that over 70 % of R&D laboratories in their network rely on glass reactors for small‑scale synthesis and crystallization, mainly because of the balance between chemical resistance, visibility, and cost compared with lined steel reactors.

6. Practical Tips for Safe and Efficient Operation

- Heat and cool gradually: avoid very fast temperature jumps to reduce thermal stress on the glass.

- Check joints and clamps: ensure all flanges, clamps, and PTFE seals are correctly seated before applying vacuum or pressure.

- Balance the stirrer: misaligned shafts can cause vibration and stress on the glass neck.

- Match impeller to process: choose anchor stirrers for viscous fluids and turbine or propeller designs for low‑viscosity or gas–liquid systems.

- Use appropriate support: always secure heavy accessories and glass components to the frame.

Do higher stirring speeds always improve reaction performance?

Based on laboratory experience, not always. Very high rpm can increase shear forces and may cause:

- Excessive foaming in gas‑releasing reactions.

- Crystal break‑up in sensitive crystallization processes.

- Unnecessary mechanical stress on the stirring assembly.

Often, a moderate stirring speed with the correct impeller type is more efficient and gentler on both the product and the equipment.

7. Summary

A borosilicate glass reactor combines transparency, chemical resistance, and modular design, making it one of the most important tools for modern chemical research and small‑scale production. When the working volume, viscosity, temperature range, and safety requirements are clearly defined, picking the right reactor — from 1 L lab systems to 100 L pilot units — becomes a straightforward, data‑driven decision.

By focusing on the key specifications discussed here and following basic operating guidelines, a borosilicate glass reactor can provide years of reliable service while giving clear insight into every reaction that takes place inside.

Note: The specifications listed above are representative values. For critical processes, always consult the detailed technical datasheet and safety instructions of the specific reactor model.