Searching for a clear answer on rotovap price? Instead of a vague “it depends,” this guide breaks down what actually drives rotary evaporator cost, using real-world specifications from 2 L to 50 L models. The goal is simple: help select the right rotovap capacity and configuration for a lab or pilot plant, without overspending on features that will never be used.

1. What Is a Rotovap and Why Does the Price Vary So Much?

A rotary evaporator (often called a rotovap) is a core piece of lab equipment for gentle solvent removal. It combines:

- A rotating evaporating flask

- A heated water or oil bath

- A condenser with collection flask

- A vacuum system and lift mechanism

The price difference between a small 2 L teaching-lab rotovap and a 50 L pilot-scale unit can be several times because the hardware and performance requirements are very different.

According to a 2023 survey by the European Federation of Chemical Engineering on laboratory investment, rotary evaporators ranked among the top five most frequently upgraded pieces of equipment when labs scaled from bench to pilot scale. That means choosing the right size at the start can avoid a second, expensive purchase two years later.

Source: EFCE Laboratory Equipment Investment Survey, 2023.

In practice, most buyers care about one question: how much capacity and performance is really needed to support daily workflows, and what does that mean for rotovap price?

2. Key Technical Factors That Drive Rotovap Price

For buyers trying to compare models, technical data sheets often look overwhelming. Based on the parameters provided for RE, R and large-capacity series, the following factors matter most for pricing and daily use:

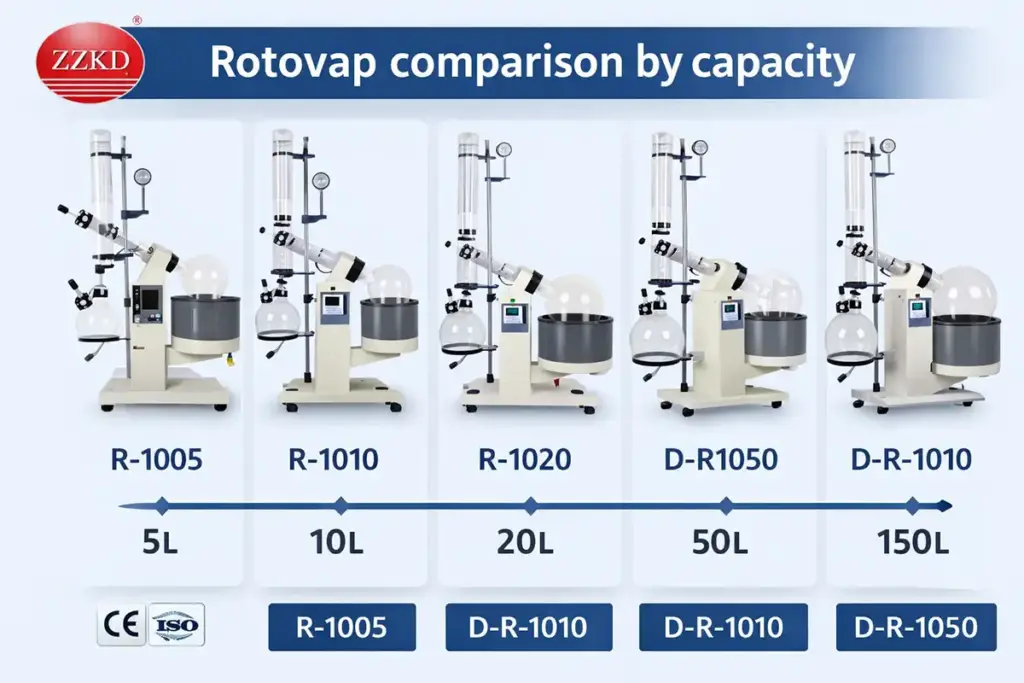

2.1 Evaporating Flask Volume (2–50 L)

Volume is usually the first driver of cost. For example, in a typical product line:

- RE‑201D / RE‑301 / RE‑501 models use 2 L, 3 L and 5 L evaporating flasks.

- RE‑1002 / RE‑2002 / RE‑5002 scale to 10 L, 20 L and 50 L.

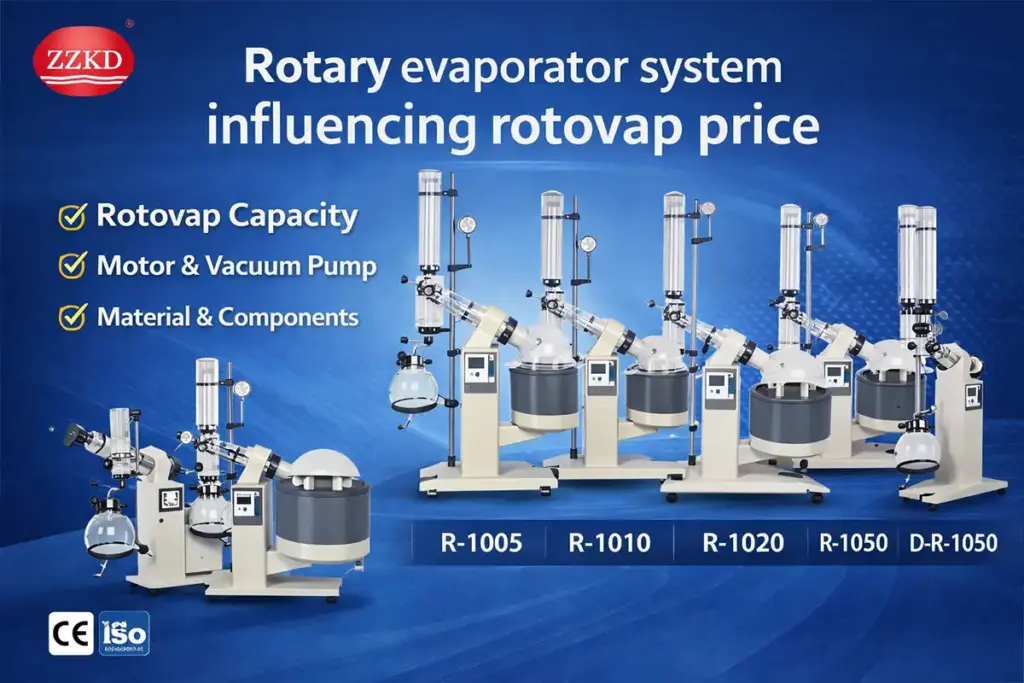

- R1005 / R1010 / R1020 / R1050 also cover 5 L, 10 L, 20 L and 50 L with higher automation.

Each step up in volume increases the size of the glassware, the condenser, the support frame, and the heating power, which all add cost.

How much daily solvent volume justifies moving from a 5 L to a 10 L or 20 L rotovap?

A practical rule used in many labs is: if the system is running near full flask volume for more than 4–5 hours per day, it is usually more economical to move up to the next capacity. For consistent production-level evaporation (several tens of liters per shift), 10–20 L becomes the default choice, and 50 L is common in pilot plants.

2.2 Heating Power and Temperature Control

Higher heating power shortens evaporation time and supports higher throughput:

- Small RE‑201D / RE‑301 / RE‑501 units use 1200–1500 W baths.

- RE‑1002 / RE‑2002 / RE‑5002 scale from 3000 W up to 5000 W and 7000/9000 W.

- Temperature control range is typically RT–99 °C (or up to 250 °C for oil bath use) with ±1–2 °C stability.

More power and tighter control increase cost but can reduce operating time and improve reproducibility, which matters in regulated or production environments.

2.3 Vacuum Performance and Evaporation Rate

For price comparison, evaporation rate is more directly useful than raw motor power. Typical specifications include:

- Small RE series: >1–1.5 L/h (water).

- RE‑1002 / RE‑2002 / RE‑5002: >3 L/h, >5 L/h and >9 L/h (water).

- Maximum vacuum often reaches <133 Pa (approx. 1.33 mbar / 1 Torr / 0.098 MPa).

The deeper and more stable the vacuum, the faster solvents can be removed at lower bath temperatures, which protects heat-sensitive compounds but requires higher-quality seals and condensers.

3. Typical Rotovap Price Ranges by Capacity

To keep this guide brand-neutral, exact numbers will vary by supplier and region. However, based on global lab-equipment catalogues and distributor quotations, the following ranges are typical for complete systems (excluding chiller and vacuum pump, which are often priced separately):

Approximate Rotovap Price Ranges by Size (System Only)

| Nominal Volume | Typical Models | Use Case | Approx. Price Range (USD) |

|---|---|---|---|

| 2–5 L | RE‑201D / RE‑301 / RE‑501 | Academic labs, R&D benches, small batches | ~$500 – $900 |

| 10 L | RE‑1002 / R1005 / R1010 | Process development, mid‑scale production | ~$2,000 – $3,000 |

| 20 L | RE‑2002 / R1020 | Pilot plants, high‑throughput labs | ~$2,500 – $4,000 |

| 50 L | RE‑5002 / R1050 | Pilot/production scale solvent recovery | $3,000 and above |

These ranges are indicative and assume standard glass sets and manual lift. Electric lift, advanced control, and custom glassware can increase the final rotovap price.

To estimate total project cost, chillers and solvent recovery systems should be considered as part of the same budget envelope. For high‑throughput or solvent‑intensive processes, pairing a rotovap with a dedicated rotary evaporator system or solvent distillation unit can often reduce long‑term operating costs compared with standalone units.

In many procurement projects, consumables and energy use over five years can cost more than the rotovap itself. When comparing quotes, it is helpful to ask vendors for estimated evaporation rate per kWh and expected seal lifetime.

4. How to Match Rotovap Specifications to Real Lab Needs

When evaluating rotovap price, the most useful step is to translate daily workloads into technical requirements. A straightforward approach is:

- Step 1 – Daily solvent volume: Estimate the average liters of solvent to remove per day and peak days.

- Step 2 – Solvent type: Water, ethanol, hexane and DMSO behave very differently; high‑boiling solvents benefit from more powerful baths and strong vacuum.

- Step 3 – Desired turn‑around time: Faster evaporation (higher L/h) allows smaller equipment to handle larger total volume.

- Step 4 – Available utilities: Check electrical supply (e.g., 220 V/50 Hz for RE‑1002 vs 380 V/50 Hz for RE‑5002), cooling water or chiller capacity, and lab ceiling height for 20–50 L units.

Is it better to buy one large 20–50 L rotovap or several smaller 5 L units?

The answer depends on how work is organized. One large unit is more efficient for processing a single high‑volume stream and can offer lower energy consumption per liter. Multiple smaller units provide flexibility and redundancy: different solvents or projects can run in parallel, and maintenance on one unit does not stop all evaporation work. When projects are diverse and time‑sensitive, several 2–5 L units can be more practical than a single 20 L system.

For labs focused on solvent-heavy processes, integrating a rotovap with a dedicated solvent recycling machine can be more cost‑effective than increasing rotovap size alone, especially where solvent regulations and disposal fees are strict.

5. Small vs. Large Rotovap Models: What Do the Specs Mean?

The technical parameters in typical datasheets can be grouped into small‑scale RE models, large‑capacity RE models, and R‑series rotovaps with more advanced automation.

5.1 Small RE Series: RE‑201D / RE‑301 / RE‑501

These models are focused on bench‑scale work:

- Evaporating flasks: 2 L, 3 L, 5 L

- Receiving flasks: 1 L, 2 L, 3 L

- Rotation: 0–120 rpm with 40 W motor

- Bath power: 1200–1500 W, temperature control RT–399 °C (intelligent digital)

- Evaporation rate: >1–1.5 L/h (water)

- Max vacuum: <133 Pa

- Lift: 0–120/150 mm

- Sealing: PTFE and fluoro rubber

For educational labs and small‑scale synthesis, this range generally provides the best price‑to‑performance ratio.

5.2 Large RE Series: RE‑1002 / RE‑2002 / RE‑5002

These models are designed for higher throughput:

- Evaporating flasks: 10 L, 20 L, 50 L

- Receiving flasks: 5 L, 10 L, 20 L

- Rotation: 0–120 rpm (10 L), 0–90 rpm (20–50 L)

- Bath power: 3000 W, 5000 W, 7000/9000 W

- Evaporation rate: >3 L/h, >5 L/h, >9 L/h

- Vertical double condensers and manual bath lifting to 220 mm

- Voltage: 220 V/50 Hz (10 L) and 380 V/50 Hz (20–50 L)

These specifications typically push the rotovap into the mid‑ to high‑price category but are essential when daily solvent removal exceeds several tens of liters.

5.3 R Series: R1005 / R1010 / R1020 / R1050

The R series adds features that influence cost and usability:

- Brush‑less motors (up to 250 W) and wider speed ranges (10–140 rpm).

- Electric lift or electric + manual lift combinations for easier operation.

- Stainless steel water baths with larger diameters (Φ300×170 mm up to Φ550×320 mm).

- Vertical main and side condensers with reflux options for higher efficiency.

- Total power up to 4 kW, especially for 50 L configurations.

These enhancements add to the rotovap price but improve ergonomics, safety and long‑term reliability, which can be decisive in GMP or 24/7 production environments.

When is it worth paying extra for electric lift and brush‑less motors?

Electric lift is very helpful once flask volumes reach 10 L and above, where manual lifting becomes physically demanding and less safe. Brush‑less motors are worth the extra cost when the rotovap is expected to run for long hours daily; they reduce maintenance and speed fluctuations, which is important in process‑critical applications.

6. Practical Steps to Optimize Rotovap Price vs. Performance

To summarize, the most effective way to control rotovap budget while getting reliable performance is:

- Define the real workload: Daily and peak solvent volumes, number of parallel projects, and typical solvent types.

- Choose capacity carefully: Avoid buying the largest unit available “just in case”; match 2–5 L, 10 L, 20 L or 50 L to actual use.

- Focus on evaporation rate, not just flask size: L/h at given solvent and temperature is more meaningful than volume alone.

- Check electrical and space constraints: Especially for 20–50 L units requiring 380 V power and taller frames.

- Evaluate lifecycle costs: Seal replacement intervals, energy efficiency, and integration with solvent recovery equipment.

For labs that regularly deal with large volumes of valuable solvents, combining an appropriately sized rotary evaporator with a dedicated recovery or solvent distillation unit can reduce total solvent purchase and waste disposal costs significantly over several years.

When comparing quotations, it is useful to request a configuration summary that clearly lists: flask size, condenser type, bath power and range, lift type, seal material, and included accessories. This makes it easier to compare different vendors on a like‑for‑like basis instead of focusing on headline price alone.

This overview is based on typical specifications for RE and R‑series rotary evaporators from 2 L to 50 L. For detailed quotations and exact rotovap price tailored to a specific application, suppliers usually need information on solvent types, batch size, and available utilities.