High Pressure Autoclave Reactor Introduction

FCF series high pressure autoclave reactor is a stirring reaction device for chemical reaction of gas-liquid, liquid-liquid, liquid-solid or gas-liquid-solid three-phase chemical materials, which can make various chemical materials under high pressure and vacuum , Stir fully at high temperature to enhance the mass transfer and heat transfer process.On the basis of CJF conventional products, FCF type adds kettle cover lifting device or according to user’s requirements, adds devices such as lower discharge valve.

High Pressure Autoclave Reactor Features:

High-pressure capacity:

High-pressure autoclave reactors are designed to handle pressures up to several thousand PSI, allowing for reactions to take place under high-pressure conditions.

High-temperature capacity:

High-pressure autoclave reactors are designed to withstand high temperatures, often up to several hundred degrees Celsius.

Variable volume:

High-pressure autoclave reactors typically have a variable volume design, allowing for precise control of the reaction volume and reactant concentration.

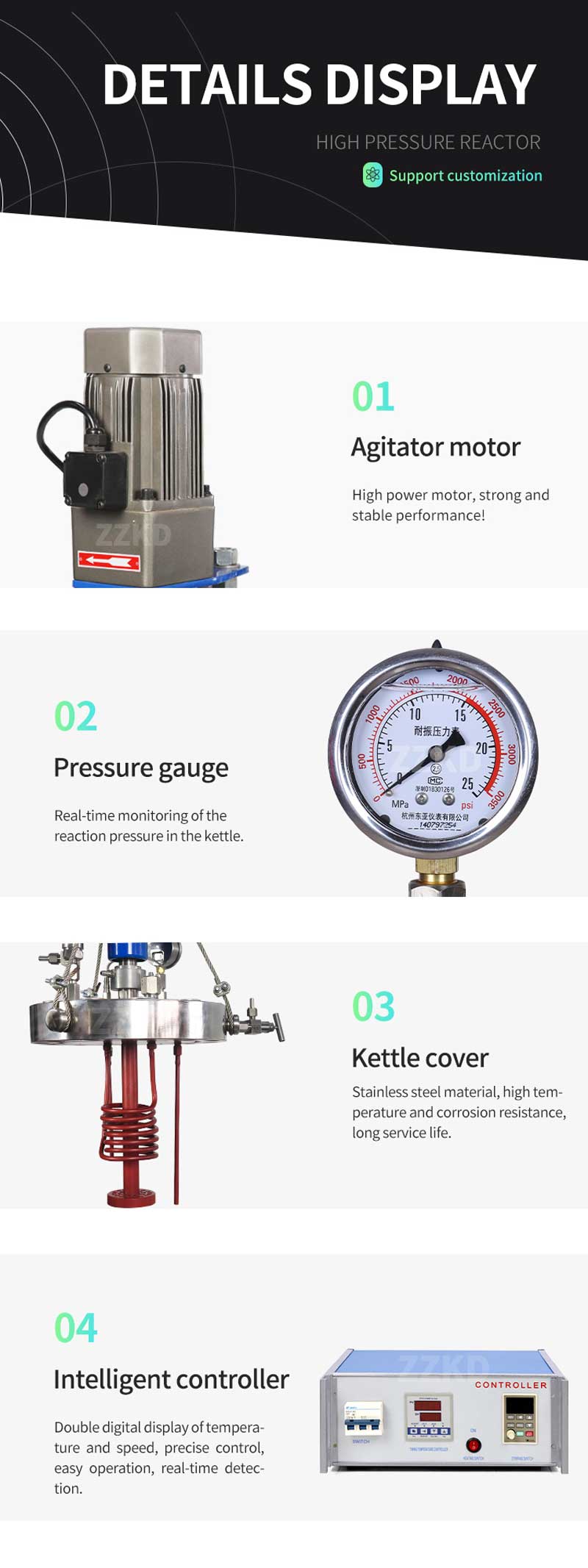

Stirring capabilities:

Many high-pressure autoclave reactors feature a stirring mechanism to ensure uniform mixing of the reactants during the reaction.

Safety features:

High-pressure autoclave reactors often have multiple safety features, such as pressure relief valves, rupture discs, and interlocks, to ensure safe operation.

Corrosion-resistant materials:

High-pressure autoclave reactors are typically made from corrosion-resistant materials, such as stainless steel or titanium, to withstand the harsh conditions of high-pressure and high-temperature reactions.

High pressure autoclave reactor Application:

Polymerization reactions:

High-pressure autoclave reactors are often used to carry out polymerization reactions under high-pressure and high-temperature conditions. These reactions can be used to create a wide range of polymeric materials with tailored properties, such as high strength, thermal stability, and chemical resistance.

Catalytic reactions:

High-pressure autoclave reactors are commonly used to carry out catalytic reactions, such as hydrogenation, oxidation, and polymerization, under high-pressure conditions. These reactions are often used to produce valuable chemicals and materials for various industrial applications.

Materials synthesis:

High-pressure autoclave reactors can be used to synthesize a wide range of materials, including ceramics, nanomaterials, and metal alloys. These reactors provide a controlled environment for materials synthesis, allowing for precise control of reaction parameters and resulting material properties.

Supercritical fluid extraction:

High-pressure autoclave reactors can be used for supercritical fluid extraction, a process used to extract compounds from solid or liquid materials using supercritical fluids. This process is often used in the pharmaceutical and food industries to extract natural compounds from plant materials.

Environmental studies:

High-pressure autoclave reactors can be used to study the behavior of materials and chemicals under high-pressure and high-temperature conditions, which is important for understanding the effects of these conditions on the environment.

High Pressure Autoclave Reactor operation:

(1) After the equipment is installed, inject a certain amount of nitrogen gas to keep the pressure for 30 minutes, and check for leakage. If there is any leakage, please use soap foam to find the leakage point of the pipeline and the nozzle. After finding out, release the gas and tighten it again. Introduce nitrogen to hold the pressure test to ensure that there is no leakage and start to work normally.

(2) When the temperature is lowered and cooled, water can be used for internal cooling through the cooling coil, and rapid cooling is prohibited to prevent excessive temperature difference and pressure from causing cracks in the cooling coil and the kettle body. Before starting the machine, it is necessary to pass cooling water through the water jacket between the magnetic stirrer and the lid of the kettle to ensure that the water temperature is less than 35°C to avoid demagnetization of the magnetic material.

(3) Installation device: It adopts positive arched metal rupture disc, made of stainless steel, which has been tested before leaving the factory and cannot be adjusted arbitrarily. If it bursts and needs to be replaced again, the replacement period is determined by the user according to the actual situation of the unit. For those that exceed the rated bursting pressure of the bursting disc but have not burst, they should be replaced. Frequent use is best not to exceed 80% of the lower limit pressure of the bursting disc. When replacing It should be noted that the convex side of the rupture disc faces upwards.

(4) After the reaction is completed, cool down first, and then release the gas in the kettle to the outside through the pipeline to reduce the pressure in the kettle to normal pressure. It is strictly forbidden to disassemble under pressure, and then loosen the main bolts and nuts symmetrically Unload, and then carefully remove the kettle cover (or raise the kettle cover) and place it on the support. During the process of removing the cover, special attention should be paid to protecting the sealing surface of the kettle body and the kettle cover.

(5) Cleaning inside the kettle: after each operation, use a cleaning solution (care should be taken to avoid corrosion of the main material when using the cleaning solution) to remove the residues on the kettle body and the sealing surface. It should be cleaned frequently and kept clean. Hard substances are not allowed. Or rough surface items for cleaning.