High pressure stirred reactor Introduction

CJF high pressure stirred reactor is a conventional autoclave.These reactors are used in a wide range of industrial processes, including polymerization, hydrogenation, and oxidation.The reactor consists of a vessel, typically made of stainless steel, which is sealed to prevent leaks. Inside the vessel, there is a stirring mechanism that mixes the reactants together and promotes heat transfer. Heating and cooling can be achieved by circulating a fluid through a jacket surrounding the vessel or by using internal coils.

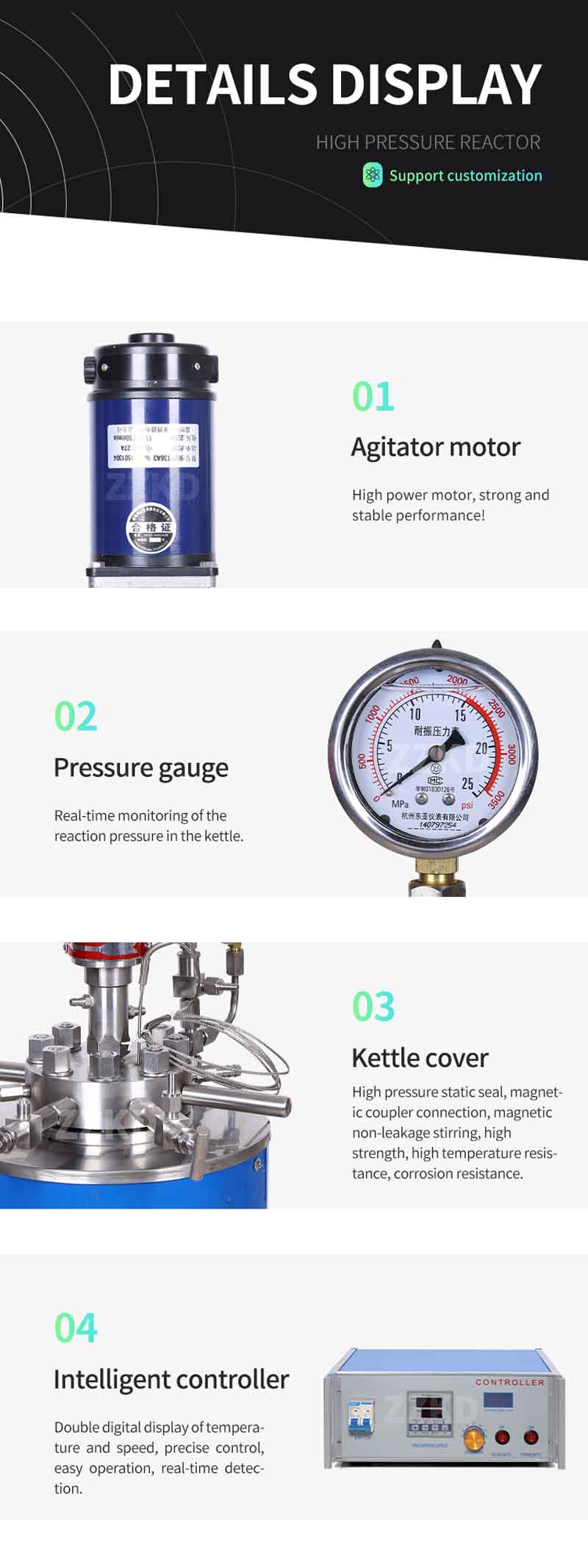

High pressure stirred reactor Features:

(1) Kettle body and lid

It is made of various austenitic stainless steel or other metal materials. The kettle body and the flange are connected by thread or directly welded. The conical surface of the kettle body is sealed with the spherical surface of the kettle cover, and the two use the uniform circumferential main bolts of the flange to achieve sealing by tightening the nuts, and the seal is reliable and leak-free.

(2) Magnetic stirrer:

The outer magnetic steel body is driven by the servo motor to rotate, and the outer magnetic steel body drives the inner magnet, stirring shaft and stirring blades to rotate through the magnetic force lines to achieve the purpose of stirring.

(3) Heater:

A barrel-shaped silicon carbide furnace core is installed outside the kettle body, and the heating resistance wire is connected in series, which has the characteristics of uniform heat conduction effect and fast heating speed.

(4) Safety blasting device

A pressure relief safety device composed of a rupture disc holder or a safety valve assembly. When the pressure difference inside the rupture disc reaches a predetermined pressure value at a predetermined temperature, the burst disc or safety valve can release the pressure medium.

(5) Feeding port

The solid feeding port is threaded or directly welded on the lid of the kettle. Use a wrench to unscrew the plug and then feed in. The feeding port should be wiped clean with soft paper first, and then tighten the plug after there are no particles. Pay special attention to the safety of the feeding port. Sealing lines remain clean.

High pressure stirred reactor Application:

Hydrothermal synthesis:

High-pressure autoclave reactors are often used for hydrothermal synthesis, which is a process that uses high pressure and temperature to synthesize materials from aqueous solutions. This technique is commonly used to synthesize nanoparticles, ceramics, and other advanced materials.

Catalyst screening and optimization:

High-pressure autoclave reactors are also used in the screening and optimization of catalysts for various chemical reactions. Researchers can use these reactors to study the effect of pressure, temperature, and reactant concentrations on catalyst performance.

Polymerization:

High-pressure autoclave reactors are used in polymerization reactions, where high pressure is needed to promote the reaction and yield high-quality polymer products.

Material testing:

High-pressure autoclave reactors can be used to test the properties of materials under high-pressure and high-temperature conditions. This is particularly useful for studying the behavior of materials in extreme environments, such as those encountered in deep sea or space exploration.

Sample preparation:

High-pressure autoclave reactors can be used for sample preparation, such as digesting or extracting materials for analysis. This is particularly useful in analytical chemistry and environmental science.

CJF high pressure stirred reactor adopts static sealing structure, which completely solves the leakage problem of stirring.

High pressure stirred reactor operation:

- Receive the goods and check whether the packing is complete.

- To debug the high pressure stirred reactor, first open the bolts of the kettle body, then lift the upper plate, add clean water, and then close the lid of the kettle. The bolts are locked symmetrically, the control power is turned on and the speed measuring device is positioned, the heating device is connected and the temperature measuring device is positioned. Then it is connected to the cooling device on the magnet, and then it can be debugged. Turn on the main power supply of the control box, adjust to the usable speed and temperature, and check whether it is normal.

- After the reaction, turn off the power, and the magnet cooling water keeps cooling; you can insert the cooling water of the kettle body to cool it below 60 degrees, open the vent valve, and discharge the gas in the attached body before opening the kettle lid to lift. After rising, loosen the rotating bolt, and rotate the upper plate to the other side. After removing the heating device, you can put out the rotating positioner, and then move the rotating handle to tilt the kettle body to a certain degree, and then take out the material. Then move the rotating handle to the original position. The lid of the kettle is lowered, and the rotating bolt is tightened. Install the heating device and fix the kettle body bolts.