Rotary evaporator purpose have become an essential tool in various scientific disciplines, including chemistry, pharmaceuticals, and food technology. This sophisticated laboratory equipment plays a crucial role in the separation and concentration of liquids, making it an invaluable asset for researchers and professionals. In this article, we will delve into the purpose of rotary evaporators, explore their applications, and provide a detailed understanding of their functionality.

I. What is a Rotary Evaporator?

A. Definition and Components

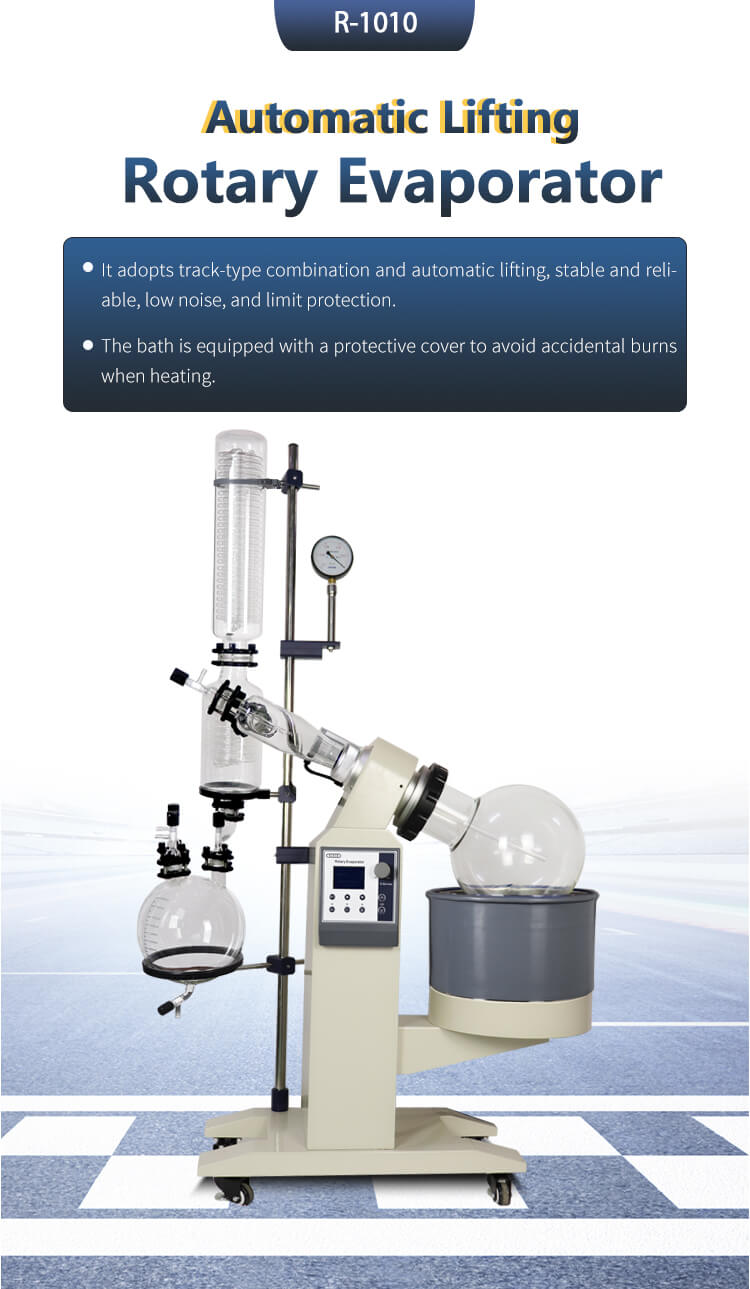

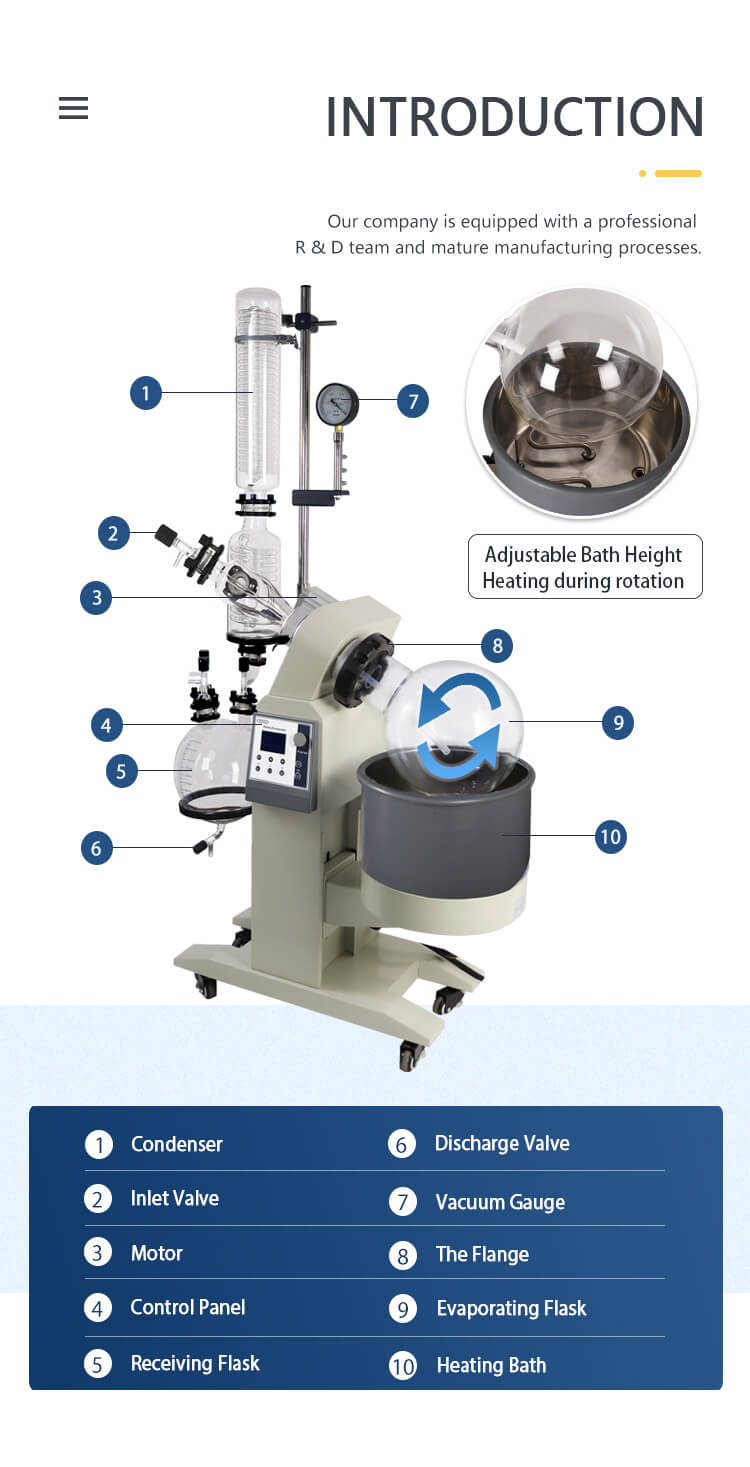

The rotary evaporator, commonly known as a rotovap, efficiently evaporates solvents from samples under reduced pressure. It consists of several key components:

1. Evaporation Flask: This is the primary container that holds the sample and the solvent to be evaporated.

2. Heating Bath: The heating bath provides controlled heating to the evaporation flask, enabling the solvent to vaporize.

3. Condenser: The condenser is responsible for converting the vaporized solvent back into its liquid form. It consists of a coil or a tube surrounded by a coolant, which cools the vapor, causing it to condense.

4. Vacuum System: The vacuum system reduces the pressure inside the system, lowering the boiling point of the solvent and facilitating its evaporation.

B. Working Principle

The rotary evaporator utilizes the principles of evaporation and condensation to separate solvents from the desired substance. The process involves the following steps:

1. The sample and the solvent are placed in the evaporation flask.

2. The flask is then rotated at a constant speed while being heated in the heating bath.

3. As the solvent heats up, it evaporates and forms a vapor, which rises up into the condenser.

4. The condenser cools the vapor, causing it to condense and collect in a separate flask.

5. The remaining solvent-free substance is left behind in the evaporation flask, ready for further analysis or processing.

II. Applications of Rotary Evaporators

Rotary evaporators find applications in a wide range of industries and scientific research. Some notable examples include:

A. Chemistry and Chemical Engineering

In the field of chemistry, rotary evaporators are used for various purposes, such as:

1. Solvent Recovery: Scientists use rotary evaporators to recover solvents from reaction mixtures, enabling reuse and reducing waste.

2. Concentration: By removing solvents, rotary evaporators concentrate solutions, enabling researchers to obtain higher concentrations of the desired compounds.

3. Distillation: Rotary evaporators facilitate the separation of volatile components from non-volatile substances through distillation techniques.

B. Pharmaceuticals and Drug Discovery

Rotary evaporators play a crucial role in pharmaceutical research and drug discovery processes, including:

1. Solvent Removal: Pharmaceutical laboratories often employ rotary evaporators to remove solvents from drug formulations, ensuring the final product is free of impurities.

2. Extraction: Rotary evaporators aid in the extraction of active pharmaceutical ingredients (APIs) from plant materials or chemical synthesis processes.

C. Food and Beverage Industry

The food and beverage industry utilizes rotary evaporators for various purposes, including:

1. Flavor Concentration: Rotary evaporators help concentrate flavors and essential oils from natural sources, intensifying their taste profiles.

2. Solvent Removal: Professionals employ them to eliminate solvents or undesirable substances from food products, ensuring safety and quality.

III. Application : Essential Oil Extraction

To illustrate the practical application of rotary evaporators, let’s consider the case of essential oil extraction. People use essential oils as highly concentrated plant extracts in aromatherapy, cosmetics, and food flavoring. Rotary evaporators offer an efficient method for extracting essential oils from plant materials.

1. Preparation: The plant material is first macerated or ground to increase the surface area, facilitating the extraction process.

2. Extraction: The plant material is placed in the evaporation flask along with a suitable solvent, such as ethanol or hexane. While heating, researchers rotate the flask, enabling the solvent to extract the essential oil components.

3. Evaporation: The solvent is evaporated under reduced pressure, leaving behind the concentrated essential oil.

4. Collection: The condenser cools and condenses the evaporated solvent, which is collected in a separate flask for reuse or disposal.

5. Final Product: The concentrated essential oil, free of solvents, is obtained and ready for further processing or use.

IV. Understanding the Functionality of Rotary Evaporators

A. Precise Temperature Control

Rotary evaporators provide precise temperature control, allowing researchers to adjust the temperature based on the boiling points of the solvents and the desired compounds. This control ensures efficient and selective evaporation while minimizing the risk of degradation or damage to heat-sensitive substances.

B. Vacuum System for Reduced Pressure

The vacuum system is a critical component of rotary evaporators, as it lowers the pressure inside the system, reducing the boiling points of the solvents. Operating at reduced pressure minimizes the risk of solvent bumping or excessive foaming, enabling safer and more efficient evaporation.

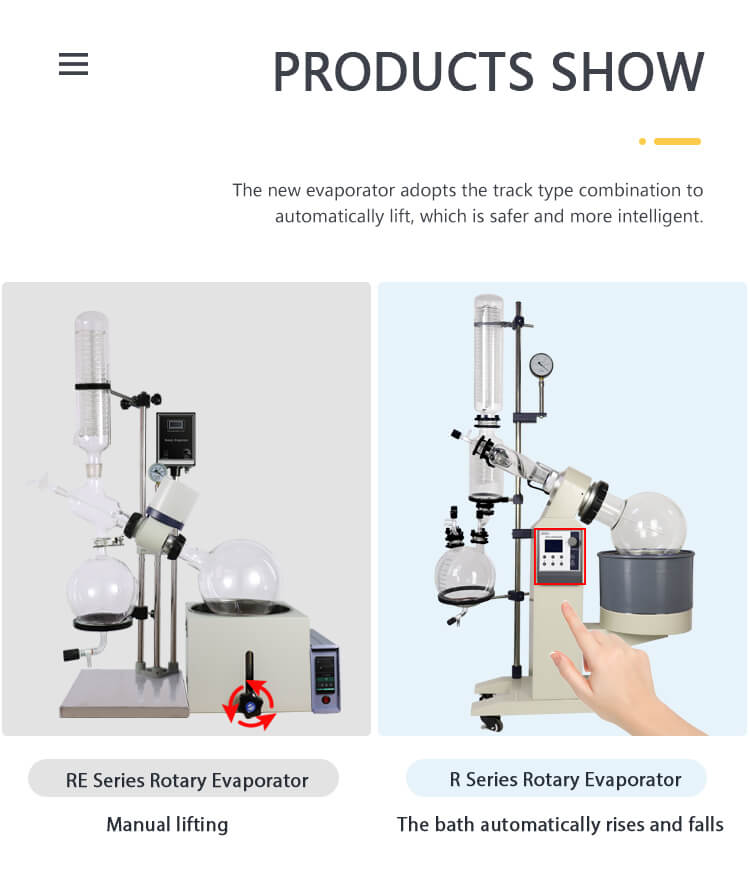

C. Flexibility and Customization

Rotary evaporators offer flexibility and customization options to meet diverse experimental requirements. Users can utilize various accessories, such as different condenser types (vertical or diagonal) or specialized flasks, to optimize the evaporation process for specific applications.

The purpose of rotary evaporators is clear: to separate and concentrate solvents through the process of evaporation and condensation. With their wide range of applications in chemistry, pharmaceuticals, and the food industry, these instruments have become indispensable in scientific research and various industrial processes. By understanding their functionality and applications, researchers and professionals can harness the power of rotary evaporators to enhance their work and drive innovation in their respective fields.