Glass lab reactors have emerged as indispensable tools in the field of scientific research and chemical synthesis. These reactors, constructed from high-quality borosilicate glass, offer exceptional visibility, chemical resistance, and versatility. They find widespread application in pharmaceutical research, chemical synthesis, petrochemical industry, and more. In this article, we will delve into the features, applications, and benefits of glass lab reactor. Furthermore, we will showcase a real-world case study that highlights the significance of these reactors in scientific research.

I. Understanding Glass Lab Reactors

Glass lab reactors, also known as glass jacketed reactors, are vessels used for conducting chemical reactions and experiments in controlled environments. Due to its exceptional thermal and chemical resistance, manufacturers typically make them from borosilicate glass. This type of glass ensures that the reactor can withstand a wide range of temperatures and corrosive chemicals, making it suitable for diverse applications.

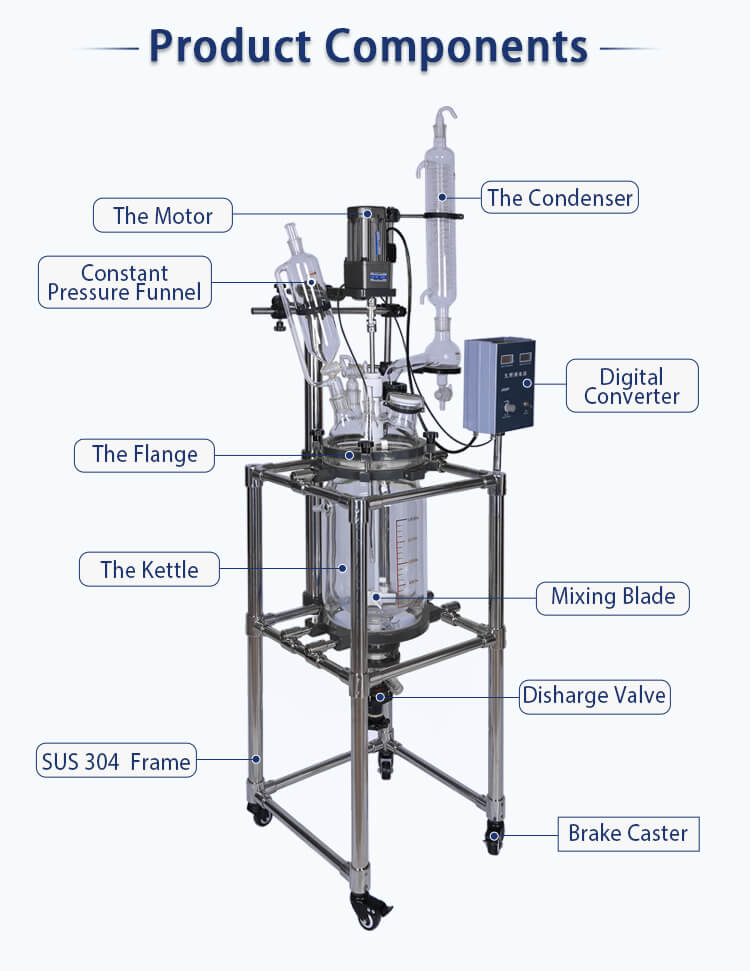

The key components of glass lab reactor include the glass vessel, which serves as the main reaction chamber, and the jacket surrounding it. The jacket allows for the circulation of temperature-controlling fluids, such as water or oil, enabling precise control over the reaction temperature. Additional components may include ports for adding reagents, stirrers for mixing the contents, and condensers for cooling and collecting volatile substances.

Glass lab reactors are available in various configurations to accommodate different experimental requirements. Common types include single-layer reactors, double-layer reactors, and triple-layer reactors. Single-layer reactors consist of a single glass vessel, while double-layer and triple-layer reactors have an additional jacket for temperature control and insulation.

II. Applications of Glass Lab Reactors

Glass lab reactor find extensive applications in various fields, owing to their versatility and functionality. Let’s explore some of the key areas where these reactors are commonly employed.

A. Pharmaceutical Research and Drug Development

In the pharmaceutical industry, glass lab reactor play a crucial role in the development and optimization of drug synthesis processes. Researchers can accurately control reaction parameters such as temperature, pressure, and mixing rate to produce pharmaceutical compounds with high purity and yield. Glass lab reactors are particularly useful for exploring new drug formulations, screening reaction conditions, and studying reaction kinetics.

B. Chemical Synthesis and Process Optimization

Researchers widely utilize glass lab reactors in chemical synthesis to produce a wide range of compounds, including fine chemicals, specialty chemicals, and intermediates. These reactors allow researchers to investigate reaction mechanisms, optimize reaction conditions, and scale up processes from laboratory to industrial scale. The excellent visibility provided by glass vessels facilitates real-time observation of reactions, ensuring better control and analysis.

C. Petrochemical Industry

The petrochemical industry relies heavily on glass lab reactor for research and development, process optimization, and quality control. These reactors enable scientists to study the behavior of various catalysts and reactants, test different reaction conditions, and optimize reaction parameters to enhance efficiency and yield. Glass lab reactors are invaluable for exploring new pathways for petrochemical production and ensuring the development of safe and sustainable processes.

D. Academic and Industrial Research

Glass lab reactors are widely utilized in academic institutions and industrial research facilities for a broad range of scientific studies. They provide a controlled environment for investigating chemical reactions, conducting polymerization studies, analyzing reaction kinetics, and developing new materials. The versatility and scalability of glass lab reactor make them indispensable tools for researchers across disciplines.

III. Glass Lab Reactors Advantages and Benefits

Glass lab reactors offer numerous advantages that make them the preferred choice for scientific research and chemical synthesis. Let’s explore some of the key benefits associated with these reactors.

A. Excellent Visibility and Observation

Glass lab reactor provide exceptional visibility, allowing researchers to closely monitor reactions in real time. This enables better control over reaction parameters and facilitates the observation of reaction kinetics, phase changes, and the formation of intermedi

ates or by-products. The ability to visually assess the progress of a reaction enhances the understanding of underlying mechanisms and aids in making informed decisions during experimentation.

B. Chemical Resistance and Compatibility

Glass lab reactors are highly resistant to corrosive chemicals, making them compatible with a wide range of reagents and solvents. The borosilicate glass used in their construction withstands harsh conditions, such as high temperatures and acidic or alkaline environments, without undergoing degradation or leaching harmful substances into the reaction mixture. This chemical resistance ensures the integrity and safety of experiments and allows for the exploration of diverse chemical reactions.

C. Versatility and Scalability

Glass lab reactors are available in various sizes and configurations, allowing researchers to choose the most suitable setup for their specific needs. Glass lab reactor offer easy scalability, making them adaptable for both small-scale laboratory experiments and large-scale industrial production. The versatility of glass lab reactor enables researchers to conduct a wide range of reactions and adapt to evolving experimental requirements.

D. Safety and Reliability

Glass lab reactor prioritize safety by providing a robust and inert environment for chemical reactions. The borosilicate glass construction ensures that the reactors can withstand high temperatures and sudden changes in pressure, minimizing the risk of accidents or equipment failure. Additionally, glass lab reactors are designed with proper insulation to prevent heat loss, reducing the chances of thermal shocks and enhancing the reliability of experimental results.

IV. Case : Glass Lab Reactors in Drug Development

To illustrate the practical application of glass lab reactors, let us consider a case study highlighting their importance in drug development.

A. Problem Statement and Objective

A pharmaceutical research team aimed to develop a novel drug compound with improved bioavailability. The team needed to optimize the reaction conditions and study the impact of various parameters on the synthesis process.

B. Experimental Setup and Methodology

The team employed a glass lab reactor with a double-layer configuration to conduct the synthesis reactions. They precisely controlled the reaction temperature using the jacketed system and monitored the progress of the reaction through the transparent glass vessel. By introducing different reagents and varying reaction parameters, such as temperature and stirring rate, they explored the optimal conditions for maximum yield and purity.

C. Results and Analysis

The glass lab reactor facilitated accurate control and observation of the reaction, allowing the team to identify the optimal reaction conditions. By fine-tuning the temperature and optimizing the reaction time, they achieved a significant improvement in the bioavailability of the drug compound. The team also monitored the reaction kinetics and identified the formation of unwanted by-products at higher temperatures, which enabled them to design a more efficient and selective synthesis process.

D. Conclusion

The case study highlights the vital role of glass lab reactor in pharmaceutical research and drug development. The precise control, excellent visibility, and chemical compatibility provided by these reactors enabled the research team to optimize the synthesis process and improve the desired drug compound’s bioavailability. Glass lab reactors are instrumental in accelerating drug discovery and development, leading to enhanced therapeutic options for various medical conditions.

V. Glass Lab Reactors Recent Advancements and Innovations

The field of glass lab reactors continues to evolve, driven by advancements in technology and the need for more efficient and sustainable chemical processes. Some of the recent developments include:

A. Automation and Remote Monitoring

Automation has revolutionized the operation of glass lab reactors, allowing for precise control and remote monitoring of reactions. Integrated systems enable researchers to program reaction parameters, monitor progress, and collect data in real time. This automation enhances productivity, minimizes human error, and facilitates continuous monitoring of critical reactions.

B. Integrated Sensors and Data Acquisition Systems

Glass lab reactors are now equipped with integrated sensors to monitor crucial parameters such as temperature, pressure, pH, and dissolved oxygen levels. These sensors provide real-time data, enabling researchers to make immediate adjustments and ensure optimal reaction conditions. The integration of data acquisition systems simplifies data collection and analysis, promoting efficient process optimization.

C. Improved Reactor Designs and Materials

Researchers and manufacturers are continuously improving reactor designs to enhance performance and functionality. Advanced designs focus on better heat transfer, improved mixing efficiency, and enhanced safety features. Furthermore, novel materials and coatings are being explored to further enhance chemical resistance and ensure the compatibility of glass lab reactors with a wider range of reagents and processes.

VI. Best Practices for Working with Glass Lab Reactors

To ensure safe and efficient use of glass lab reactors, it is essential to follow best practices:

A. Proper Handling and Maintenance

Glass lab reactors should be handled with care to avoid damage or breakage. Regular inspections and maintenance are necessary to identify any defects or signs of wear. Proper cleaning and storage procedures should be followed to maintain the integrity of the reactor.

B. Safety Precautions and Risk Management

Safety should be a top priority when working with glass lab reactors. Appropriate personal protective equipment (PPE) should be worn, and standard safety protocols should be followed. Risk assessments should be conducted to identify and mitigate potential hazards associated with specific reactions or chemicals.

C. Cleaning and Sterilization Techniques

Thorough cleaning and sterilization of glass lab reactors are crucial to prevent contamination and ensure the accuracy of experimental results. Proper cleaning techniques using compatible solvents and detergents should be employed, followed by sterilization methods such as autoclaving or dry heat sterilization.

D. Regular Calibration and Validation

Glass lab reactors should be regularly calibrated and validated to maintain accuracy and reliability. Calibration of temperature sensors, pressure gauges, and other monitoring devices should be performed as per the manufacturer’s instructions. Validation studies should be conducted to verify the reactor’s performance and ensure consistent results.

VII. Future Prospects and Emerging Trends

The future of glass lab reactors holds exciting prospects and emerging trends that will shape the field of chemical research:

A. Continuous Flow Reactors

Continuous flow reactors are gaining prominence as they offer several advantages over batch reactors. These reactors allow for continuous processing, precise control over reaction parameters, and efficient use of reagents. Integration of continuous flow systems with glass lab reactors holds promise for rapid reaction optimization and large-scale production.

B. Integration with Artificial Intelligence and Machine Learning

The integration of glass lab reactors with artificial intelligence (AI) and machine learning (ML) algorithms opens up new avenues for data-driven optimization and predictive modeling. AI-driven systems can analyze vast amounts of experimental data, identify patterns, and suggest optimal reaction conditions. This integration paves the way for accelerated reaction development and process optimization.

C. Sustainable and Green Chemistry

With growing environmental concerns, there is a rising focus on sustainable and green chemistry practices. Glass lab reactors can contribute to this shift by enabling the development of cleaner and more sustainable chemical processes. By facilitating precise control, reduced waste generation, and efficient use of resources, glass lab reactor are poised to play a significant role in advancing sustainable chemical synthesis.

Glass lab reactor have revolutionized the field of chemical research, enabling scientists to conduct experiments with precision, safety, and efficiency. Their excellent visibility, chemical resistance, and versatility make them indispensable tools in pharmaceutical research, chemical synthesis, and the petrochemical industry. Furthermore, recent advancements in automation, sensor technology, and reactor design have enhanced their capabilities and opened up new possibilities in process optimization and sustainable chemistry.

By adhering to best practices and staying updated with emerging trends, researchers can harness the full potential of glass lab reactor. These reactors not only accelerate discoveries and innovation but also contribute to the advancement of science and technology. As we move towards a future driven by data and sustainable practices, glass lab reactors will continue to evolve, integrating with emerging technologies and shaping the scientific landscape for years to come.