10L rotary evaporator introduction

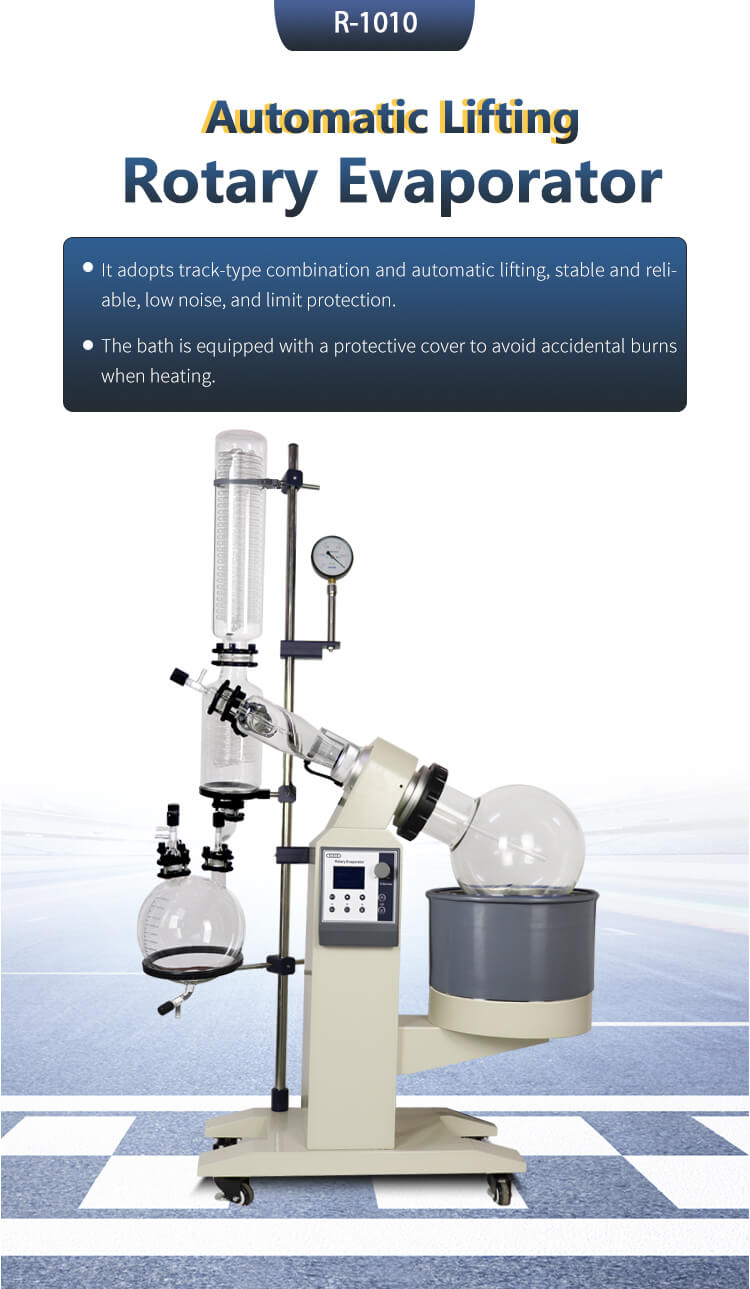

A 10L rotary evaporator is composed of three main parts: the heating bath, the evaporating flask, and the condensing unit. The heating bath, which is made of stainless steel or aluminum, is where the sample flask is placed and heated to the desired temperature. The evaporating flask, which is usually made of high-quality borosilicate glass, holds the sample to be evaporated.

The condensing unit is responsible for cooling and condensing the evaporated solvent into a liquid form, allowing it to be collected and reused. In addition to these core components, the 10L rotary evaporator also includes a vacuum pump, a control panel, and various safety features to ensure reliable and safe operation. With its efficient and precise design, the 10L rotary evaporator is a powerful tool for laboratory work, particularly for larger-scale operations.

10L Rotary Evaporator Features:

Large capacity: The 10L rotary evaporator has a larger evaporating flask and heating bath, allowing for larger volume sample processing.

Efficient evaporation: The more powerful vacuum pump and larger surface area of the evaporating flask enable faster and more efficient solvent evaporation.

High-quality materials: The evaporating flask and condensing unit are made of high-quality borosilicate glass, which is resistant to heat, chemicals, and corrosion.

Easy-to-use controls: The device is equipped with user-friendly controls and a digital display for precise temperature and vacuum level settings.

Safety features: The 10L rotary evaporator comes with various safety features, including a safety shield to prevent splashing and an automatic shut-off feature in case of power failure.

Versatility: The device can be used for various applications, including natural product extraction, distillation, and solvent removal.

Compact design: Despite its larger size, the 10L rotary evaporator is designed to take up minimal space in the laboratory.

Robust construction: The device is made with sturdy materials, ensuring a long lifespan and reliable performance.

10L Rotary Evaporator Application:

A 10L rotary evaporator is a versatile laboratory instrument with a range of applications, including:

Solvent removal: The device is commonly used to remove solvents from chemical mixtures, such as in drug discovery and material science research.

Natural product extraction: It can also be used for the extraction of natural products from plants, herbs, and other organic materials.

Distillation: The 10L rotary evaporator is capable of distilling large volumes of samples, making it useful for producing high-purity substances.

Concentration: The device is often used to concentrate samples, such as in food and beverage research.

Purification: It can also be used to purify samples and remove impurities, such as in biochemistry and molecular biology research.

The 10L rotary evaporator is a powerful tool for laboratory work, particularly for larger-scale operations that require efficient and precise sample processing.

Supporting Equipment for 10L Rotary Evaporator:

DLSB-20/30 Refrigerated Circulator

Storage Volume: 20L

Low temperature range: -30℃~RT

Refrigeration capacity: 246~1845W

Rated Power: 1350W

SHZ-C Water Circulating Vacuum Pump

Power: 370W

Flow(L/min): 80

Lift(m): 12

Max.Vacuum(Mpa): 0.098

Tank Capacity: 50L

Case : ZZKD Company Selling 10L Rotary Evaporator to customers in England

ZZKD Company, a leading manufacturer of laboratory equipment, recently sold a 10L rotary evaporator to a research team in England. The customer, a university laboratory specializing in natural product extraction, required a larger capacity rotary evaporator to process larger volumes of samples in a single run.

After consulting with the ZZKD sales team, the customer chose the 10L rotary evaporator due to its efficient evaporation rate, larger evaporating flask, and user-friendly controls. The device was also equipped with safety features, such as a safety shield to prevent splashing and an automatic shut-off feature in case of power failure.

The 10L rotary evaporator was delivered to the customer’s laboratory and installed by a ZZKD technician. The research team was impressed with the device’s performance, particularly its ability to process larger volumes of samples and its precise temperature and vacuum level control.

Overall, the customer was satisfied with the product and the customer service provided by ZZKD. They praised the company’s prompt communication and efficient delivery, and have since recommended ZZKD to other research teams in their field.