10l Rotovap introduction

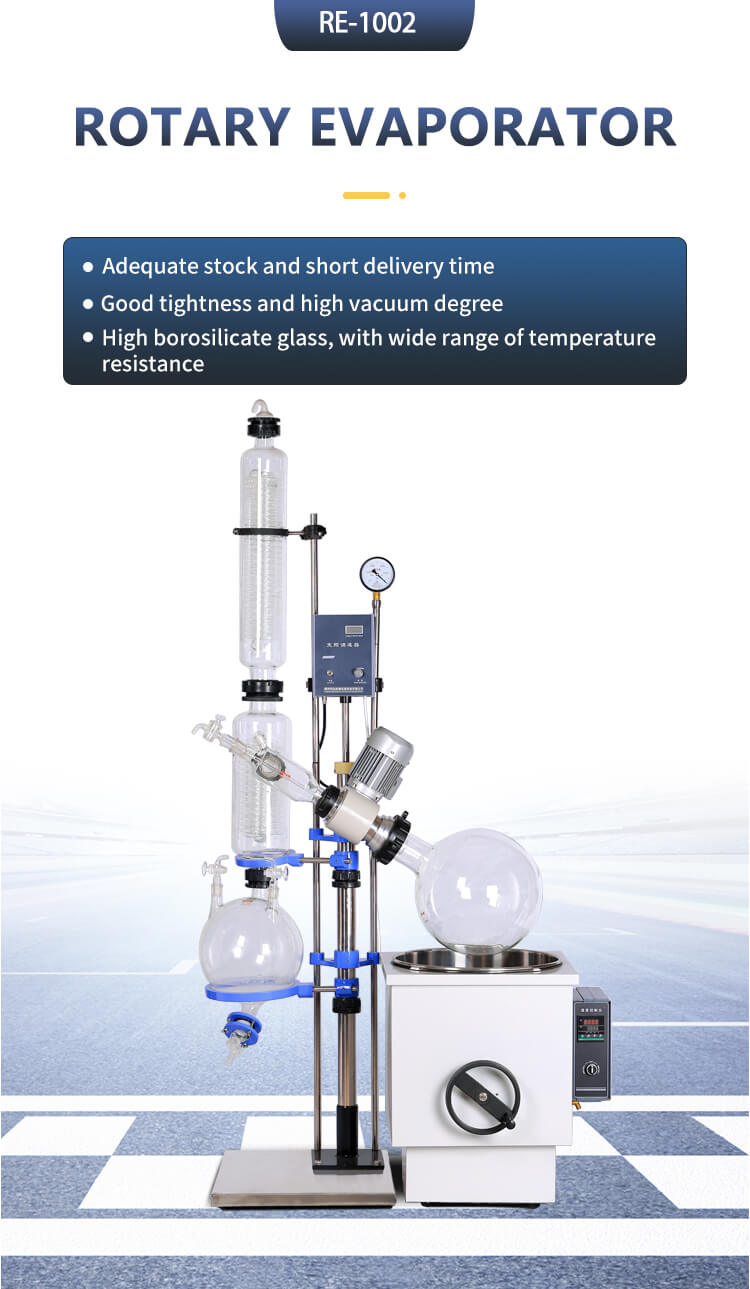

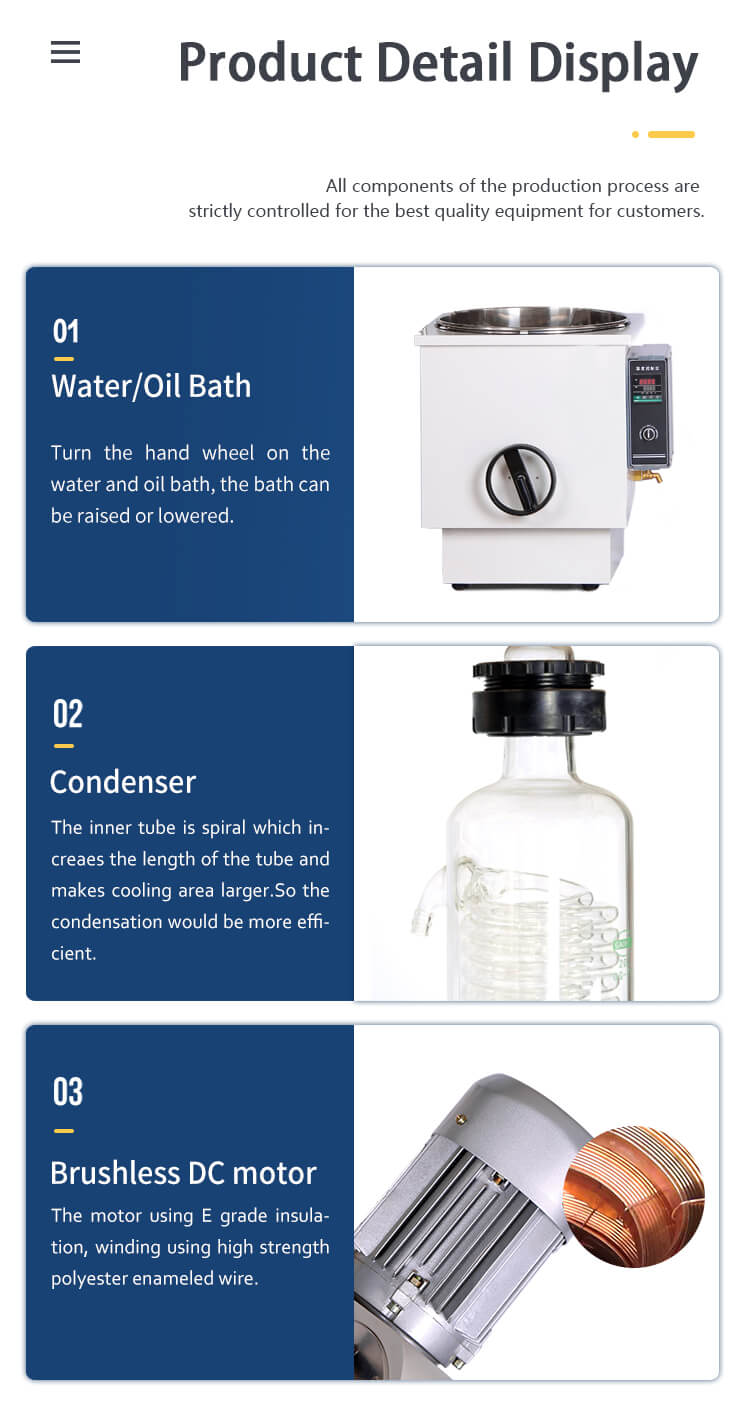

A 10L rotovap, also known as a 10-liter rotary evaporator, is a laboratory device used for efficient and precise evaporation and concentration of liquids. It consists of a heating bath, rotary flask, condenser, vacuum pump, and other components. The sample is placed in the rotary flask and rotated at a controlled speed, while the heating bath provides heat to evaporate the solvent.

The resulting vapor is condensed by the condenser and collected for further processing. The 10L capacity makes it suitable for medium-scale experiments in research and development, chemical synthesis, and other applications. Its compact design and user-friendly interface make it easy to operate and maintain, while its high-quality materials ensure durability and reliability. The 10L rotovap is a versatile and essential tool for any laboratory requiring efficient and precise evaporation and concentration of liquids.

10l Rotovap Features:

Large capacity: With a 10-liter capacity, it can handle medium-scale experiments and processes.

Precise temperature control: The heating bath is equipped with precise temperature control, allowing for accurate and consistent evaporation.

Efficient evaporation: The rotary flask rotates at a controlled speed, providing efficient and thorough evaporation.

Easy-to-use interface: The user-friendly interface allows for easy operation and monitoring of the process.

High-quality materials: The rotovap is made of high-quality materials to ensure durability and reliability.

Versatile: The rotovap can be used for a wide range of applications, such as chemical synthesis, research and development, and quality control.

Safety features: The rotovap is equipped with safety features to prevent accidents, such as automatic shut-off and over-temperature protection.

Easy to clean: The design of the rotovap makes it easy to clean and maintain.

10l Rotovap Application:

A 10L rotovap is a versatile piece of equipment that can be used in various applications, including:

Chemical synthesis: The rotovap is commonly used in chemical synthesis processes, such as reaction and distillation processes.

Purification: It can be used to purify compounds and solvents, such as removing impurities from a sample.

Research and development: It is commonly used in research and development laboratories to develop and test new products and processes.

Quality control: The rotovap can be used in quality control processes, such as testing the purity and concentration of samples.

Extraction: It can be used for extracting essential oils, flavors, and fragrances from natural products.

Pharmaceutical industry: The rotovap is used in the pharmaceutical industry for drug discovery, development, and production.

Food industry: It is used in the food industry for the extraction and concentration of flavors and fragrances.

The 10L rotovap is a versatile and essential piece of equipment in various industries and laboratories.

Supporting Equipment for 10L Rotary Evaporator:

DLSB-20/30 Refrigerated Circulator

Storage Volume: 20L

Low temperature range: -30℃~RT

Refrigeration capacity: 246~1845W

Rated Power: 1350W

SHZ-C Water Circulating Vacuum Pump

Power: 370W

Flow(L/min): 80

Lift(m): 12

Max.Vacuum(Mpa): 0.098

Tank Capacity: 50L

Case : ZZKD Company Selling 10l Rotovap to Spanish Customer

ZZKD Company has recently sold a 10L Rotovap to a customer in Spain. The customer is a research laboratory at a prestigious university in Madrid, focused on the development of new drugs and therapeutic compounds. The laboratory needed a reliable and efficient rotary evaporator to purify and concentrate their chemical samples for analysis and testing.

The laboratory’s main challenge was to purify complex chemical mixtures, which required the use of a high-capacity rotary evaporator capable of processing large volumes of solvent. The laboratory was also concerned with the precision and safety of the device, as they needed to process sensitive and hazardous chemical compounds.

ZZKD’s 10L Rotovap was the ideal solution for the laboratory’s needs. The Rotovap’s large capacity allowed for the processing of high volumes of solvent, while its advanced temperature control system ensured the precision and safety of the evaporation process. The Rotovap’s digital display also made it easy for the laboratory technicians to monitor and adjust the temperature and vacuum levels during the evaporation process.

ZZKD’s Rotovap also came with a variety of safety features, including an overheat protection system, a safety cut-off switch, and a built-in vacuum release valve, which ensured the safety of the laboratory technicians and prevented damage to the device. The laboratory technicians were also pleased with the device’s user-friendly interface and ease of maintenance.

After the purchase, ZZKD provided the laboratory with a comprehensive user manual and training to ensure proper installation and use of the device. The laboratory was also provided with prompt technical support, and any issues were quickly resolved by the ZZKD team.

Overall, the laboratory was extremely satisfied with their purchase of ZZKD’s 10L Rotovap. The device proved to be reliable, efficient, and safe, allowing the laboratory to streamline their chemical processing operations and improve their research productivity. The laboratory technicians also appreciated the excellent customer support provided by ZZKD.