In modern scientific research and industrial processes, precise and efficient drying is often a critical step. Lab vacuum drying oven have emerged as invaluable tools for carrying out such tasks. Advanced ovens create controlled low-pressure environments, enabling users to remove moisture and solvents without causing damage. In this article, we will explore the working principles, applications, benefits, and an interesting case study of a lab vacuum drying oven.

Understanding Lab Vacuum Drying Oven

Specialized equipment, known as lab vacuum drying oven or vacuum dryers, find use in laboratories, research institutions, and industrial settings. These ovens operate under reduced pressure conditions, which significantly lowers the boiling point of liquids. As a result, materials can be dried at lower temperatures, reducing the risk of thermal degradation. A vacuum pump removes air and gases, creating a controlled environment for oxygen-free drying processes.

Lab vacuum drying oven have double-walled chambers with high-quality insulation, ensuring minimal heat loss and improved energy efficiency. Typically, manufacturers construct the inner chamber with corrosion-resistant stainless steel for safe accommodation of various materials and chemicals. The oven’s control panel allows users to set and adjust temperature, pressure, and time parameters according to specific drying requirements.

Applications of Lab Vacuum Drying Oven

The versatility of lab vacuum drying oven makes them indispensable in numerous applications across various industries. Some common applications include:

1. Pharmaceutical Industry: In pharmaceutical research and production, lab vacuum drying ovens are used to dry sensitive compounds, herbs, and medicines without compromising their potency and efficacy. The low-temperature drying process helps retain the chemical properties of pharmaceutical products, ensuring high-quality end products.

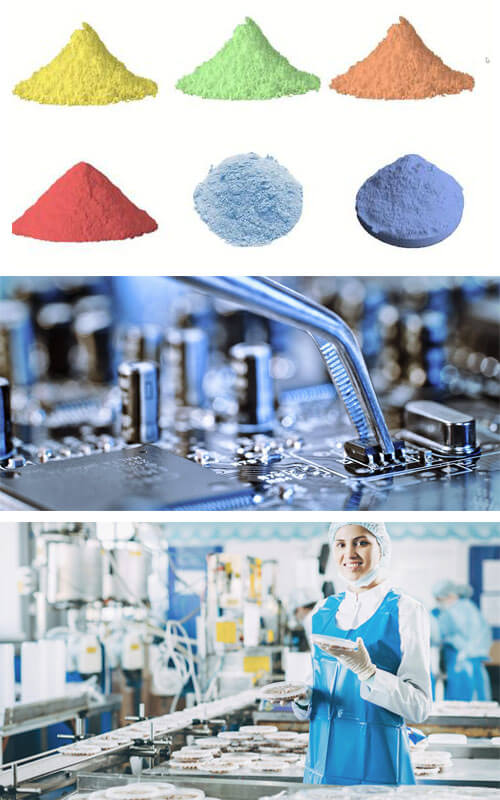

2. Chemical Laboratories: Many chemical reactions involve solvents, which need to be removed from the final product. Lab vacuum drying oven facilitate this process by efficiently evaporating solvents without raising the temperature to levels that could damage the substance.

3. Materials Testing: In material science, researchers use vacuum drying ovens to prepare samples for further testing and analysis.

4. Food Industry: Vacuum drying ovens are utilized to preserve food products by gently removing moisture without altering their nutritional content or taste. This method is particularly valuable for delicate food items like fruits, herbs, and spices.

5. Electronics Manufacturing: In the electronics industry, vacuum drying ovens are employed to remove moisture from delicate components and circuits.

6. Academic Research: Academic laboratories benefit from vacuum drying oven in various fields, including biology, chemistry, physics, and environmental science. These ovens aid in sample preparation and precise drying for analytical experiments.

Advantages and Benefits of Lab Vacuum Drying Oven

Lab vacuum drying oven offer several advantages over traditional drying methods. Some of the key benefits include:

1. Gentle Drying Process: The low-temperature drying process in a vacuum oven minimizes the risk of thermal degradation, making it ideal for sensitive materials.

2. Uniform Drying: The controlled environment inside the vacuum chamber ensures even distribution of heat and pressure, resulting in uniform drying across all parts of the material.

3. Time Efficiency: Vacuum drying ovens typically offer faster drying times compared to conventional ovens, reducing overall processing time and increasing productivity.

4. Versatility: These ovens can accommodate a wide range of materials, making them suitable for diverse applications in various industries.

5. Energy Efficiency: The double-walled chamber and efficient insulation contribute to reduced heat loss and energy consumption, making lab vacuum drying oven environmentally friendly and cost-effective.

6. Preservation of Properties: By drying materials at lower temperatures, the vacuum drying process helps preserve the chemical and physical properties of the materials being processed.

A Real-life Application Case

Let’s consider a real-life application case in the field of botanical research:

Case: Drying of Medicinal Herbs

At a botanical institute, a research team studied medicinal properties of herbs found in a remote rainforest. These herbs were delicate and susceptible to degradation when exposed to high temperatures. The team needed a drying solution that would preserve the chemical integrity of the herbs while removing moisture for further analysis.

The researchers chose a lab vacuum drying oven to preserve the herbs’ active compounds during low-temperature drying. By controlling pressure and temperature parameters, the team could customize drying conditions for each herb, optimizing subsequent studies.

The vacuum drying oven preserved medicinal properties and enabled simultaneous work with multiple herb samples for the research team. The efficiency of the oven’s drying process significantly reduced the time required to prepare samples, accelerating the overall research progress.

Maintenance and Safety Considerations of Lab Vacuum Drying Oven

To ensure the lab vacuum drying oven’s proper functioning and maintain a safe working environment, one should consider several maintenance and safety aspects:

1. Regular Calibration: Periodic calibration of the oven’s temperature and pressure sensors is essential to ensure accurate and consistent drying results.

2. Cleaning and Sterilization: Regular cleaning of the chamber and accessories is necessary to prevent contamination and cross-contamination between different samples.

3. Proper Ventilation: Adequate ventilation in the laboratory space is crucial to avoid the buildup of potentially harmful fumes or gases during the drying process.

4. Training and Supervision: Operators should be well-trained in using the vacuum drying oven and should follow safety protocols to avoid accidents and injuries.

5. Emergency Shutdown Procedures: Clear instructions for emergency shutdown procedures should be easily accessible near the oven to address any unforeseen situations promptly.

6. Preventive Maintenance: Implementing a preventive maintenance schedule can help identify and address potential issues before they escalate, ensuring the oven’s longevity and reliability.

Conclusion

Lab vacuum drying oven have become indispensable tools in modern research and industrial processes. Their controlled low-pressure environment provides a gentle and efficient solution for drying sensitive materials while preserving their properties.

Lab vacuum drying oven offer a wide range of applications and numerous benefits, making them a valuable investment for laboratories and industries alike. From pharmaceutical research to materials testing and food preservation, the versatility and precision of these ovens drive advancements in various fields, propelling scientific progress forward.

As technology evolves, we can expect further refinements in vacuum drying techniques, leading to even more sophisticated and efficient solutions for diverse drying challenges. With ongoing improvements, these ovens will continue to play a crucial role in meeting the evolving demands of scientific and industrial communities.