Laboratory vacuum oven Introduction

A laboratory vacuum oven is a piece of equipment commonly used in scientific and industrial laboratories for drying or dehydrating samples, as well as for low-temperature processing of materials. The vacuum oven works by reducing the air pressure inside the oven, which lowers the boiling point of water and other solvents, allowing for more efficient and gentle drying of heat-sensitive materials.

Laboratory vacuum oven features:

Chamber:

The vacuum oven chamber is usually made of stainless steel, which is durable, resistant to corrosion, and easy to clean.

Heating System:

The heating system is designed to provide a uniform and controlled temperature within the chamber. It may use electric heaters or infrared radiation to heat the samples.

Temperature Control:

A digital temperature controller is used to regulate and maintain the temperature inside the chamber. This allows for precise temperature control, which is important for many scientific applications.

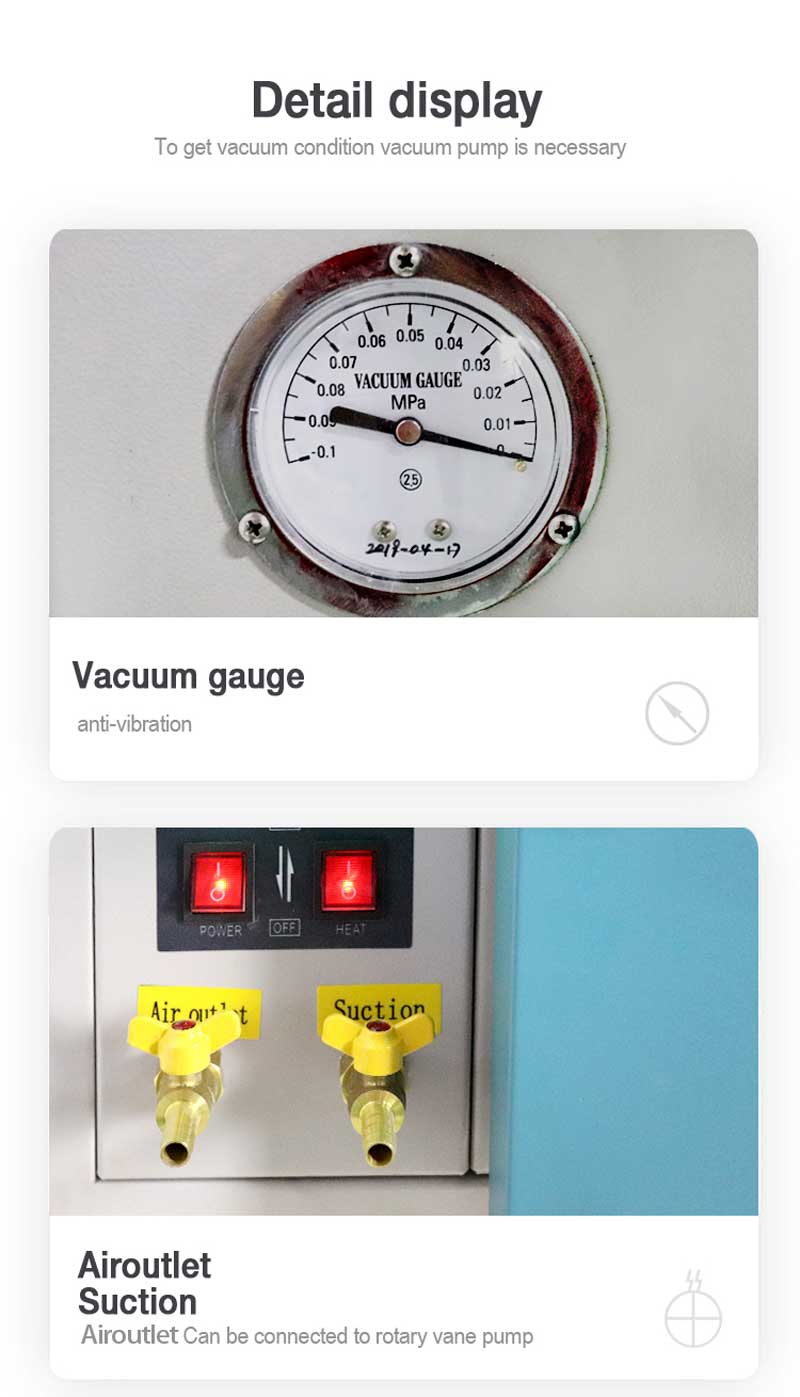

Vacuum Pump:

A vacuum pump is used to lower the air pressure inside the chamber. The pump may be oil-sealed or oil-free, depending on the application.

Safety Features:

Laboratory vacuum ovens are equipped with various safety features, such as over-temperature protection, automatic shutoff, and pressure relief valves.

Viewing Window:

Some vacuum ovens have a viewing window that allows users to monitor the samples without opening the chamber.

Shelves:

Vacuum ovens may have adjustable shelves that allow for efficient use of space and easy loading and unloading of samples.

Programmable Settings:

Some advanced models of vacuum ovens may have programmable settings that allow users to set and save temperature and vacuum profiles for specific applications.

Laboratory vacuum oven application:

Laboratory vacuum ovens have a wide range of applications in various scientific and industrial fields. Here are some common applications:

Drying and Dehydration:

Vacuum ovens are commonly used for drying and removing moisture from heat-sensitive samples such as food, pharmaceuticals, and biological materials.

Sterilization:

Vacuum ovens are also used for sterilization of equipment, glassware, and other materials that cannot be sterilized using high-temperature methods.

Curing and Processing:

Vacuum ovens can be used for curing and processing of materials such as polymers, composites, and ceramics at low temperatures and reduced pressure.

Degassing:

Vacuum ovens are used for degassing of materials such as resins, epoxies, and adhesives by removing trapped air bubbles.

Aging and Testing:

Vacuum ovens can be used for aging and testing of materials such as plastics, rubbers, and electronics at elevated temperatures and reduced pressure.

Environmental Simulation:

Vacuum ovens can be used for environmental simulation testing such as humidity, temperature, and pressure cycles on materials and products.

Operation of laboratory vacuum oven

Load the oven:

The first step is to load the oven with the material to be processed. The material should be placed on the oven shelf or tray, which is typically made of stainless steel or aluminum.

Set the parameters:

The next step is to set the temperature and vacuum parameters according to the requirements of the material being processed. The temperature is usually set using a digital controller or thermostat, while the vacuum level is controlled using a vacuum pump and pressure gauge.

Start the vacuum pump:

Once the temperature and vacuum parameters have been set, the vacuum pump can be turned on to create a vacuum inside the oven. The vacuum pump will remove air and other gases from the oven chamber, creating a low-pressure environment that is conducive to drying or processing the material.

Monitor the process:

While the material is being processed, it is important to monitor the oven temperature and vacuum level to ensure that they remain within the specified range. If the temperature or vacuum level deviates from the set point, adjustments may need to be made to ensure that the material is processed correctly.

Finish the process:

Once the processing is complete, the vacuum pump can be turned off, and the oven can be allowed to cool down before the material is removed. The material can then be inspected and tested to ensure that it meets the required specifications.

Case of laboratory vacuum oven:

A research laboratory was working on a project that involved synthesizing a new organic compound that was heat-sensitive and prone to degradation when exposed to air. The compound needed to be dried and purified before it could be used in further experiments.

The researchers decided to use a vacuum oven to dry the compound because it provided a gentle and efficient way to remove the solvent without damaging the compound. They loaded the compound onto a stainless steel shelf inside the vacuum oven and set the temperature and vacuum parameters according to the compound’s requirements.

After several hours of heating under reduced pressure, the compound was successfully dried and purified. The researchers were able to obtain a high yield of the compound, which was of sufficient purity to be used in subsequent experiments.

Without the vacuum oven, it would have been challenging to dry the compound without degrading it or losing some of it in the process. The vacuum oven provided a safe and effective way to handle the heat-sensitive compound and obtain the desired outcome.