High temperatur vacuum oven Introduction

high temperatur vacuum oven is an industry-specific equipment developed by our company to adapt to the rapid development of the new energy industry. It has rich configurations and can be filled with inert gas to achieve better anti-oxidation purposes; the main It is used in the testing of vacuum and high-temperature processes in the lithium battery industry and the rapid drying of materials that are heat-sensitive, easy to decompose, easy to oxidize, and complex in composition. It can also be used for accelerated drying of powder and other materials.

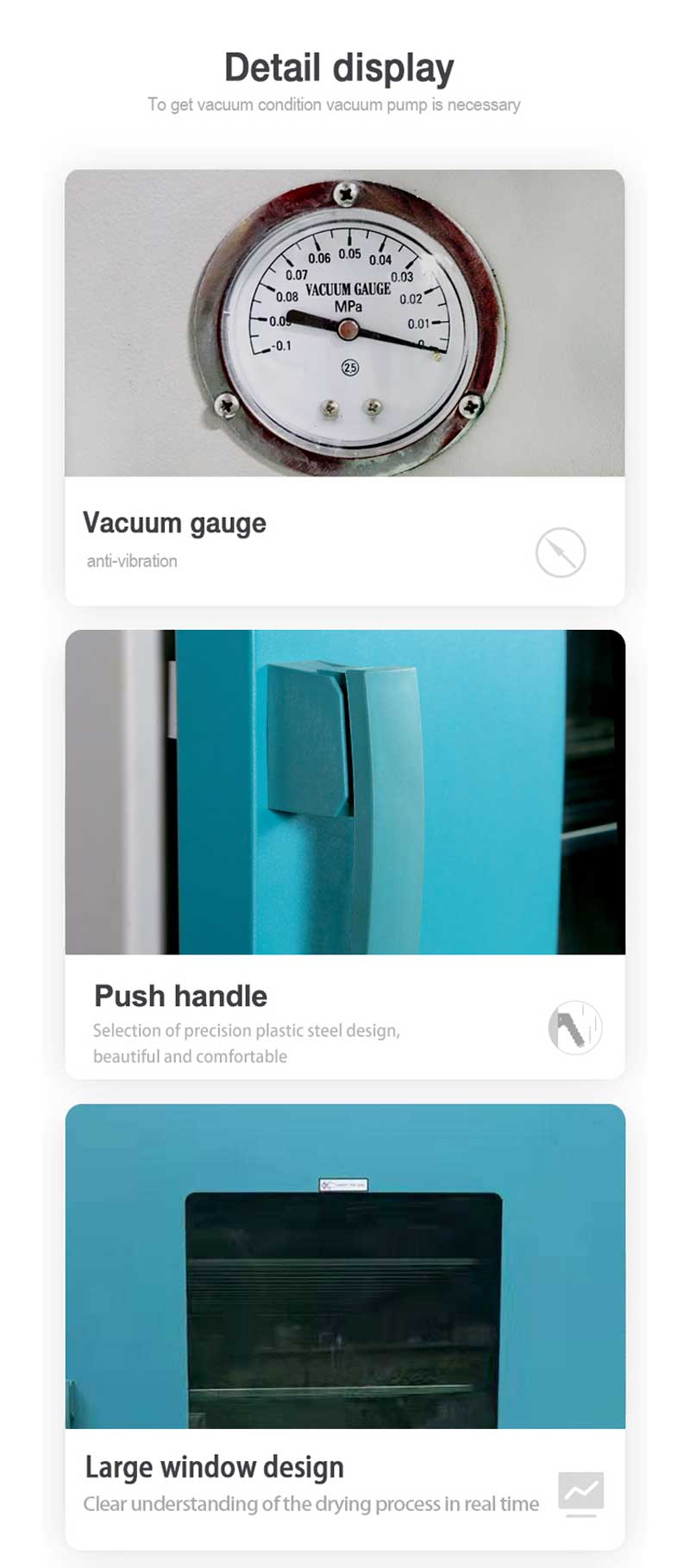

High temperatur vacuum oven features:

Safety protection

- Over temperature alarm

- Leakage protection

- Fast fuse

- Ground protection

Optional accessories

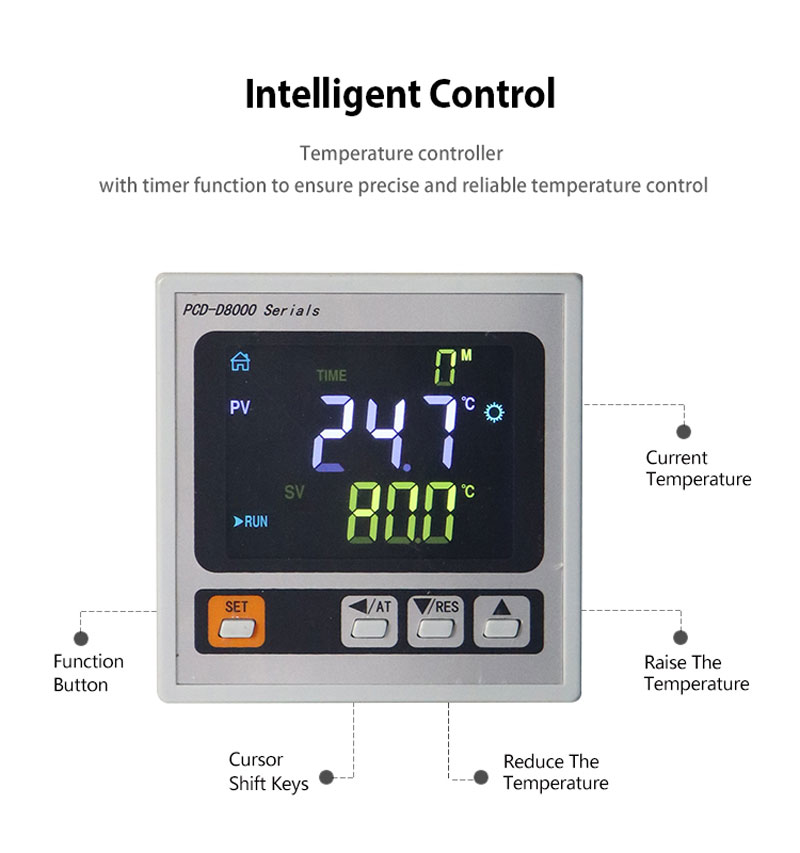

- Intelligent temperature program controller

- Independent temperature limit controller (mechanical)

- Nitrogen filling interface

- Oil mist filter

Technical advantages

- The vacuum environment greatly reduces the boiling point of the liquid that needs to be expelled, so vacuum drying can be easily applied to heat-sensitive substances.

- For samples that are not easy to dry, such as powder or granular samples, vacuum drying can effectively shorten the drying time.

- high temperatur vacuum oven is used for all kinds of complex mechanical parts or other porous samples after cleaning, and no residual substances are left after being completely dried.

- It is safer to use, under vacuum or inert conditions, completely eliminates the possibility of thermal explosion of oxides.

- Compared with ordinary drying relying on air circulation, powdery samples will not be blown or moved by flowing air.

Operation of high temperatur vacuum oven

1.Regularly clean the interior and exterior of the oven with a non-abrasive cleaner and soft cloth.

2.Keep the oven’s seals and gaskets clean and lubricated to ensure a tight seal.

3.Check the vacuum pump oil level and replace it as needed to ensure smooth operation.

4.Inspect the heating elements and thermocouples regularly for signs of wear or damage.

5.Calibrate the temperature controller periodically to ensure accurate temperature readings.

6.Follow the manufacturer’s recommended maintenance schedule for all components.

Case of high temperatur vacuum oven:

How to Dry Herbs in a Vacuum Dryer? Where is the advantage? Share real case illustrations.

DZF-6500 high temperature vacuum oven is a drying equipment commonly used in food, medicine and other fields. Below is a case story about how to use DZF-6500 high temperature vacuum oven for herb drying process.

This company is a company that produces Chinese herbal medicines. They have been using the traditional drying method to dry Chinese herbal medicines. However, there are many problems in this method, such as being greatly affected by weather conditions, easily polluted, etc., resulting in unstable drying quality. In order to improve these problems, the company decided to introduce a DZF-6500 high temperature vacuum oven.

Before using the DZF-6500 high temperature vacuum oven for herbal drying, they first inspected and maintained the equipment to ensure the normal operation of the equipment. Then, they set the appropriate parameters according to the characteristics of the herb and the drying requirements. The specific parameters are as follows:

- Temperature: 50°C

- Vacuum degree: -0.09MPa

- Drying time: about 10 hours

During the drying process, the herbs are placed in the plate, and after entering the DZF-6500 high temperature vacuum oven, the plate starts to rotate, and the herbs gradually lose moisture through heating to achieve the purpose of drying. At the same time, the vacuum pump takes the air out of the box to form a vacuum state, further promoting the drying effect of herbs.

By using the DZF-6500 high temperatur vacuum oven, the company successfully solved the problems existing in the traditional drying method, improving the efficiency and quality of herbal drying while reducing the risk of contamination.

In general, DZF-6500 high temperatur vacuum oven has the following advantages in drying herbs:

- Efficient: Vacuum drying technology is adopted, which can quickly evaporate the moisture inside the herbal medicine, thus speeding up the drying speed.

- Stable quality: Precise parameter setting can be carried out according to the characteristics and requirements of herbal medicines to ensure the stable quality of herbal medicines.

- Environmental protection: Under the vacuum state, no pollutants will be produced during the drying process, which meets the requirements of environmental protection.