DZF 6050 Vacuum Oven Introduction

The DZF-6050 vacuum oven adopts a rectangular chamber with a capacity of 50 liters and a maximum temperature of 250°C. The chamber is made of stainless steel and designed to be corrosion resistant and durable. The vacuum in the chamber can be adjusted from atmospheric pressure to 0.1 mbar using a vacuum pump, sold separately.

DZF-6050 vacuum oven is commonly used in pharmaceutical, chemical, food industries, and research laboratories for processing heat-sensitive materials. It is a reliable and efficient tool for drying, curing and processing materials requiring low pressure environments.

DZF 6050 Vacuum Oven Features:

Rectangular chamber:

The DZF-6050 vacuum oven features a rectangular chamber with a volume of 55 liters, which provides ample space for processing and drying various materials.

Temperature range:

The oven can reach a maximum temperature of 250°C, which can be controlled using a digital temperature controller with an LED display.

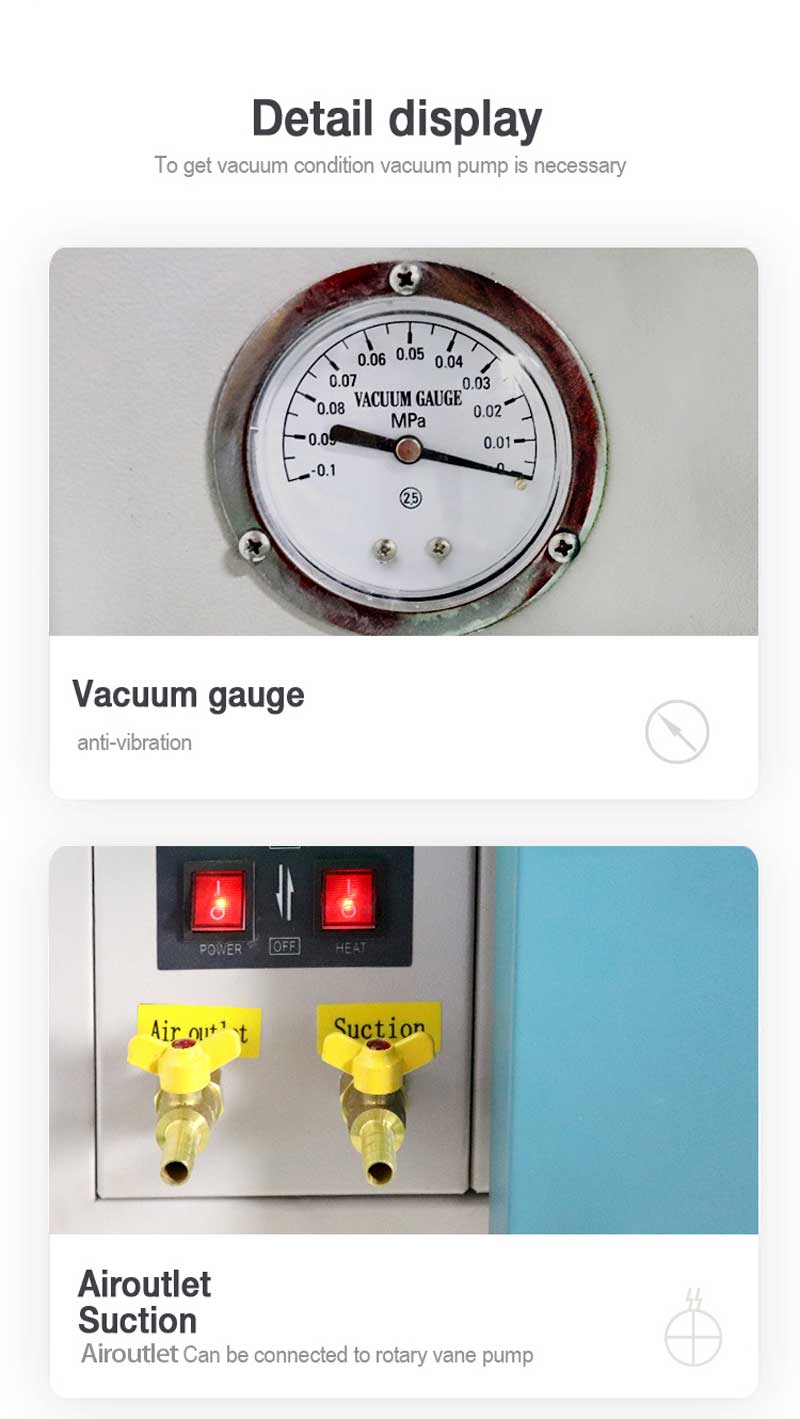

Vacuum level:

The vacuum level inside the chamber can be adjusted from atmospheric pressure down to 0.1 mbar using a vacuum pump, which is sold separately.

Chamber material:

The chamber is made of stainless steel, which is corrosion-resistant and durable, ensuring a long service life.

Safety features:

The oven is equipped with a safety valve to prevent overpressure and a safety switch to shut off the heating element in case of overheating.

Door design:

The oven door is made of tempered glass, which allows users to observe the drying process without opening the door and disrupting the vacuum. The door also features a silicone rubber seal to maintain the vacuum pressure inside the chamber.

DZF 6050 Vacuum Oven Application:

Drying of heat-sensitive materials:

The DZF-6050 vacuum oven is often used for the drying of heat-sensitive materials that cannot be processed at high temperatures. The vacuum environment inside the oven helps to prevent oxidation and other reactions that could damage the material.

Curing of coatings and adhesives:

The DZF-6050 vacuum oven is also used for the curing of coatings and adhesives. The low-pressure environment inside the oven helps to remove air bubbles from the material, ensuring a smooth and uniform finish.

Sterilization of medical instruments:

The DZF-6050 vacuum oven can be used for the sterilization of medical instruments and equipment. The low-pressure environment inside the oven helps to remove moisture and other contaminants, ensuring that the instruments are clean and sterile.

Aging of electronic components:

The DZF-6050 vacuum oven is often used for the aging of electronic components, such as capacitors and resistors. The low-pressure environment inside the oven helps to remove moisture from the components, ensuring their long-term reliability.

Testing of materials:

The DZF-6050 vacuum oven can also be used for testing the properties of materials under low-pressure and high-temperature conditions. This is particularly useful for materials that will be used in high-stress applications.

Maintenance:

Clean the oven regularly:

The oven should be cleaned after each use to remove any debris or residue that may have accumulated during the process. Use a soft cloth and mild detergent to clean the interior and exterior surfaces of the oven. Do not use abrasive cleaners or tools that could scratch or damage the surfaces.

Check the door seal:

The door seal should be checked regularly to ensure it is in good condition and free from cracks or tears. The seal helps to maintain the vacuum pressure inside the chamber, and a damaged seal can affect the oven’s performance.

Inspect the heating elements:

The heating elements should be inspected regularly to ensure they are free from damage or corrosion. Damaged heating elements can affect the oven’s temperature control and may need to be replaced.

Monitor the vacuum pump:

If a vacuum pump is used with the oven, it should be monitored regularly to ensure it is working properly. Check the pump’s oil level, and replace the oil if necessary. The pump’s filters should also be inspected and cleaned or replaced as needed.

Perform calibration checks:

The oven’s temperature controller should be calibrated regularly to ensure accurate temperature control. Calibration checks can be performed using a calibrated thermometer or other temperature measurement device.

Schedule professional maintenance:

It is recommended to have a professional technician perform annual maintenance on the DZF-6050 vacuum oven. This can include a comprehensive inspection of the oven’s components, cleaning, calibration, and any necessary repairs or replacements.

Case of DZF 6050 Vacuum Oven :

A pharmaceutical company was developing a new drug formulation that required the drying of heat-sensitive materials at low temperatures. The company decided to use a DZF-6020 vacuum oven for this process because of its ability to operate at low temperatures and low pressure.

The company first prepared the material to be dried and placed it in the oven. They set the temperature and vacuum level according to the material’s requirements and started the drying process. The vacuum pump was used to remove air and moisture from the chamber, ensuring that the material dried quickly and evenly.

After a few hours, the drying process was complete. The company removed the material from the oven and performed some tests to ensure that it had dried properly. The results showed that the DZF-6020 vacuum oven had successfully dried the material without damaging its properties.

The company continued to use the DZF-6020 vacuum oven for this process and other similar applications. They found that the oven’s precise temperature and vacuum controls, as well as its compact size, made it an ideal choice for their laboratory’s needs.