Spray drying is one of the most versatile and widely used methods for producing powdered materials in industries ranging from food and pharmaceuticals to chemicals and ceramics. The end product of this process is known as spray dried powder — a fine, free-flowing powder that retains the essential properties of the original liquid feed.

What is Spray Dried Powder?

Spray dried powder is created by transforming a liquid mixture into a dry powder in a single step. This is achieved by atomizing the liquid into a hot drying medium, typically air, causing rapid evaporation of the solvent. The resulting particles are collected as a dry powder with controlled size, moisture content, and flow properties.

What makes spray drying preferable over traditional drying methods?

Spray drying offers extremely fast drying rates (milliseconds), which helps preserve sensitive components such as proteins, flavors, and active pharmaceutical ingredients. It also allows for precise control over particle size and moisture content, ensuring consistent quality.

How Does a Spray Dryer Work?

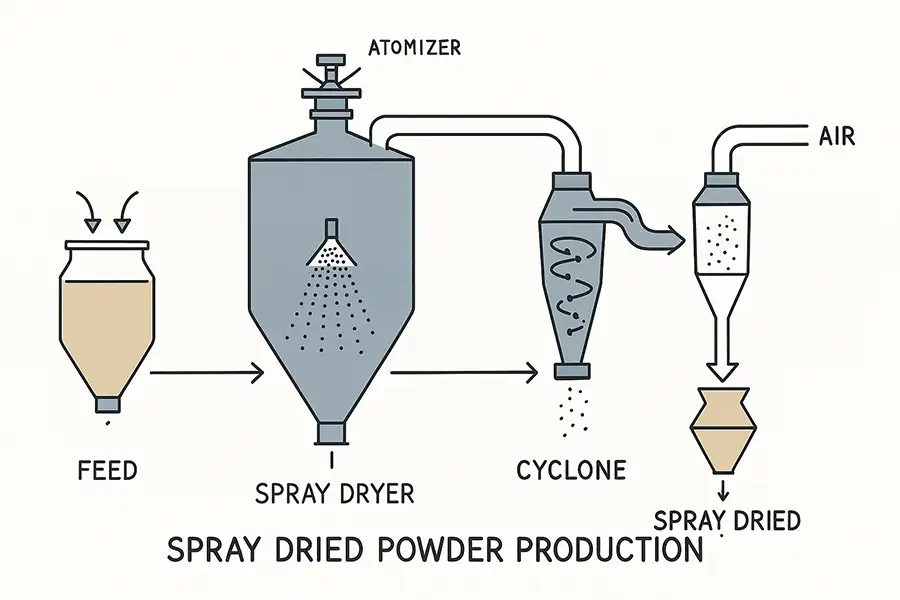

A spray dryer operates in three main stages:

- Atomization – The liquid feed is converted into fine droplets using a nozzle or rotary atomizer.

- Drying – The droplets are exposed to a stream of hot air, causing rapid evaporation.

- Powder Collection – The dried particles are separated from the air using cyclones, bag filters, or electrostatic precipitators.

Key Advantages

- Fast and continuous process

- Uniform particle size distribution

- Ability to handle heat-sensitive materials

- Scalable from laboratory to industrial production

Applications of Spray Dried Powder

The versatility of spray drying means it is used in a wide range of industries:

| Industry | Example Products |

|---|---|

| Food & Beverage | Milk powder, coffee, flavorings |

| Pharmaceuticals | Antibiotics, inhalable drugs |

| Chemicals | Catalysts, detergents |

| Ceramics | Ceramic powders for tiles |

How is particle size controlled in spray drying?

Particle size is influenced by the atomization method, feed properties, and drying conditions. For example, using a smaller nozzle or higher atomization pressure produces finer particles.

Scientific Insights and Industry Trends

According to a study by the Massachusetts Institute of Technology (MIT), advanced manufacturing technologies, including automated spray drying systems, are expected to increase production efficiency by up to 40% by 2030. This shift is driven by the demand for higher quality powders and more sustainable production methods.

In the food industry, the global spray drying market is projected to grow at a CAGR of 7.2% from 2023 to 2030, fueled by demand for instant foods and nutritional supplements.

Choosing the Right Spray Dryer

When selecting a spray dryer, factors such as production scale, feed properties, and desired powder characteristics must be considered. For laboratory-scale research, a mini spray dryer is ideal. For small-scale commercial production, a small spray dryer or benchtop spray dryer can be used.

Can spray drying be used for heat-sensitive materials like probiotics?

Yes. By carefully controlling the inlet and outlet temperatures, spray drying can preserve the viability of probiotics and other sensitive bioactive compounds.

Conclusion

Spray dried powder technology is a cornerstone of modern manufacturing, enabling the production of high-quality powders with tailored properties. Whether in pharmaceuticals, food, or industrial chemicals, spray dryers provide efficiency, scalability, and product consistency that few other drying methods can match.