In the world of food processing, pharmaceuticals, and chemical engineering, drying technologies play a crucial role in preserving products and extending shelf life. Two of the most common methods are spray drying and freeze drying. While both have their merits, understanding their differences can help in making the right choice for industrial or laboratory applications.

What is Spray Drying?

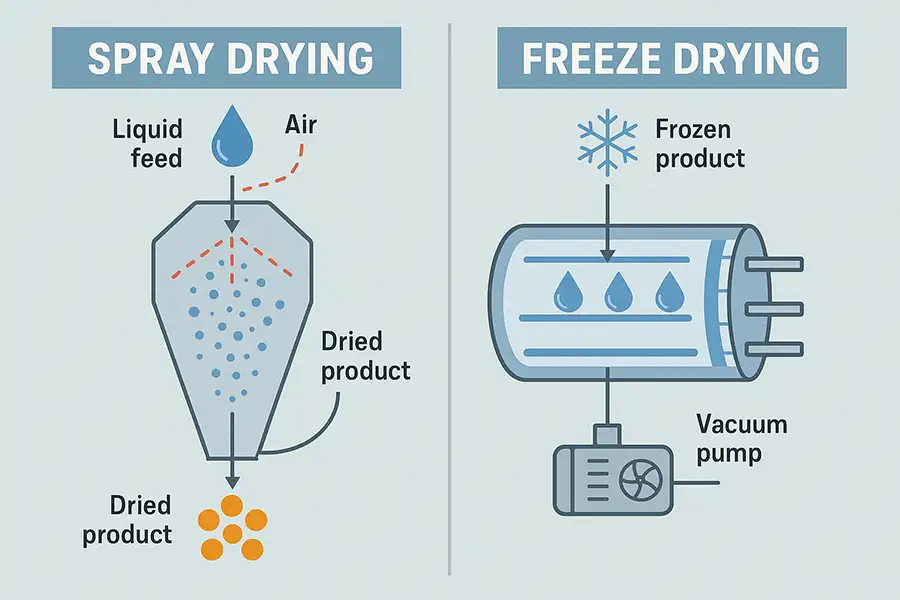

Spray drying is a method where a liquid feed is atomized into a hot drying medium, rapidly removing moisture and producing a dry powder in seconds. This technology is widely used for milk powder, coffee, pharmaceuticals, and even advanced ceramics. According to a report by MarketsandMarkets, the global spray drying equipment market is projected to reach USD 6.5 billion by 2026, driven by demand for instant food products.

What is Freeze Drying?

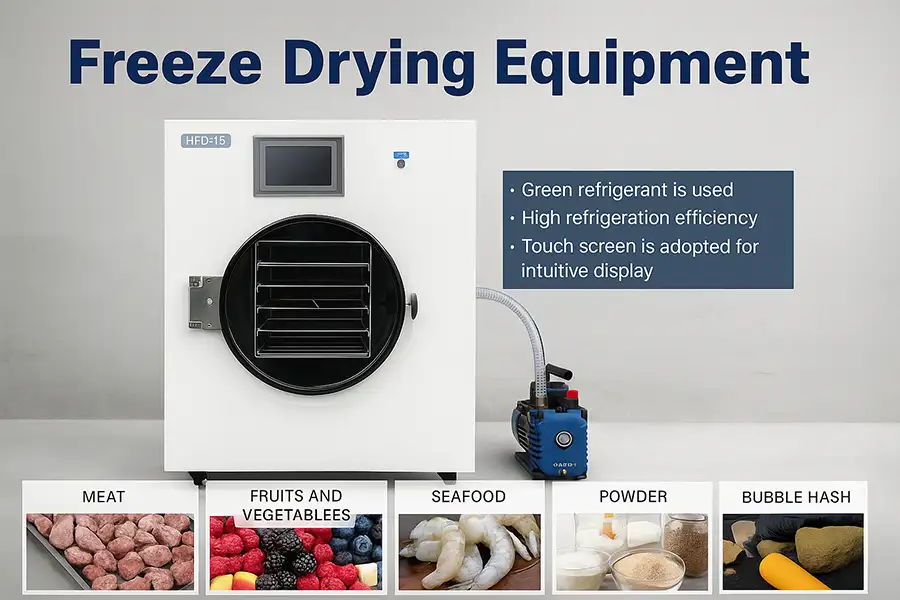

Freeze drying, or lyophilization, involves freezing the product and then reducing the surrounding pressure to allow the frozen water to sublimate directly from solid to gas. This process is slower and more energy-intensive but preserves more heat-sensitive compounds. It’s often used for pharmaceuticals, biological samples, and high-value foods.

How much faster is spray drying compared to freeze drying?

Spray drying can complete the drying process in a matter of seconds, whereas freeze drying may take hours or even days depending on the batch size and material. This speed advantage translates into higher throughput and lower operational costs for large-scale production.

Key Differences Between Spray Drying and Freeze Drying

| Parameter | Spray Drying | Freeze Drying |

|---|---|---|

| Processing Speed | Seconds to minutes | Hours to days |

| Energy Consumption | Lower per unit product | Higher due to freezing and vacuum |

| Cost Efficiency | High for large volumes | Lower for large volumes |

| Heat Sensitivity | Not ideal for extremely heat-sensitive materials | Excellent for heat-sensitive materials |

| End Product Texture | Fine powder | Porous, sponge-like structure |

Which method is more cost-effective for large-scale production?

For large-scale production, spray drying is generally more cost-effective due to its rapid processing time, lower energy consumption, and simpler operational requirements. Freeze drying, while offering superior preservation for delicate materials, incurs significantly higher energy and equipment costs.

Why Choose Spray Drying?

Spray drying offers several advantages for industries looking for efficiency and scalability:

- Faster processing time

- Lower operational costs

- High scalability for industrial production

- Consistent product quality

For example, our mini spray dryer is designed for both research and small-scale production, offering precise control over particle size and moisture content.

Can spray drying handle heat-sensitive materials at all?

Yes, to some extent. By optimizing inlet and outlet temperatures, spray drying can process moderately heat-sensitive materials. However, for extremely delicate compounds such as live probiotics or certain pharmaceuticals, freeze drying remains the preferred method.

Real-World Applications

Spray drying is widely used in:

- Food industry (milk powder, coffee, flavors)

- Pharmaceuticals (antibiotics, excipients)

- Chemicals (ceramics, catalysts)

Freeze drying is preferred for:

- Biological samples

- Vaccines

- Space food

Conclusion

Both spray drying and freeze drying have their place in modern industry. The choice depends on the product characteristics, budget, and production scale. However, for most industrial applications where speed, cost, and scalability are priorities, spray drying stands out as the more efficient and economical choice.

Interested in exploring spray drying solutions? Check out our Mini Spray Dryer Machine for lab and pilot-scale use.