Milk spray dryers are essential equipment in the food industry, utilized for converting liquid milk into powdered form efficiently. This article elucidates what milk spray dryers are, how they function, and their associated advantages.

What is a Milk Spray Dryers

A milk spray dryer is a specialized device designed to transform liquid milk into powdered milk through the process of spray drying. This equipment plays a crucial role in the dairy industry, facilitating the production of milk powder used in various food products and beverages.

How Does a Milk Spray Dryers Work

The operation of a milk spray dryer involves the following steps:

1. Atomization: Liquid milk is pumped into the top of the spray dryer, where it is atomized into small droplets using a high-pressure nozzle or rotary atomizer. This atomization process creates a large surface area for evaporation.

2. Drying Chamber: The atomized milk droplets are introduced into a drying chamber, where they come into contact with hot air or gas. The hot air rapidly evaporates the moisture from the milk droplets, leaving behind fine milk powder particles.

3. Separation: As the milk powder particles are formed, they are carried along with the airflow towards the bottom of the drying chamber. At the bottom, a cyclone separator or bag filter separates the dried milk powder from the exhaust air.

4. Collection: The separated milk powder is collected in a receiver or cyclone collector for further processing or packaging. Any remaining moisture or fine particles are typically removed through additional filtration or sieving.

Advantages of Milk Spray Dryers

Milk spray dryers offer several advantages, making them indispensable in the dairy industry:

1. Efficiency: Milk spray dryers can process large volumes of liquid milk into powdered form quickly and efficiently, resulting in high production throughput.

2. Extended Shelf Life: The spray drying process helps to preserve the nutritional quality of milk while extending its shelf life. The powdered milk produced is less susceptible to spoilage and microbial contamination compared to liquid milk.

3. Versatility: Milk spray dryers can be customized to produce different types of milk powder, including whole milk powder, skim milk powder, and whey powder, to meet specific customer requirements.

4. Reduced Transportation Costs: Powdered milk occupies less space and has a lower weight compared to liquid milk, reducing transportation costs and storage requirements.

5. Enhanced Solubility: Milk powder produced using spray drying has excellent solubility properties, making it easy to reconstitute in water or other liquids for use in various food and beverage applications.

Is It Advantageous for Businesses to Invest in a Milk Spray Dryer?

Absolutely, investing in a milk spray dryer can offer significant advantages for businesses across various industries. However, the extent of these benefits may vary depending on the specific needs and objectives of the company. When contemplating such an investment, businesses often have diverse motivations. Some prioritize improving the efficiency of milk processing and preservation, while others focus on enhancing the quality and shelf life of milk-based products. Similar to customers considering various factors when selecting products, such as price, quality, and reliability, businesses must also carefully evaluate different aspects to choose the most suitable milk spray dryer for their operations.

How Can Businesses Determine the Right Milk Spray Dryer for Their Needs?

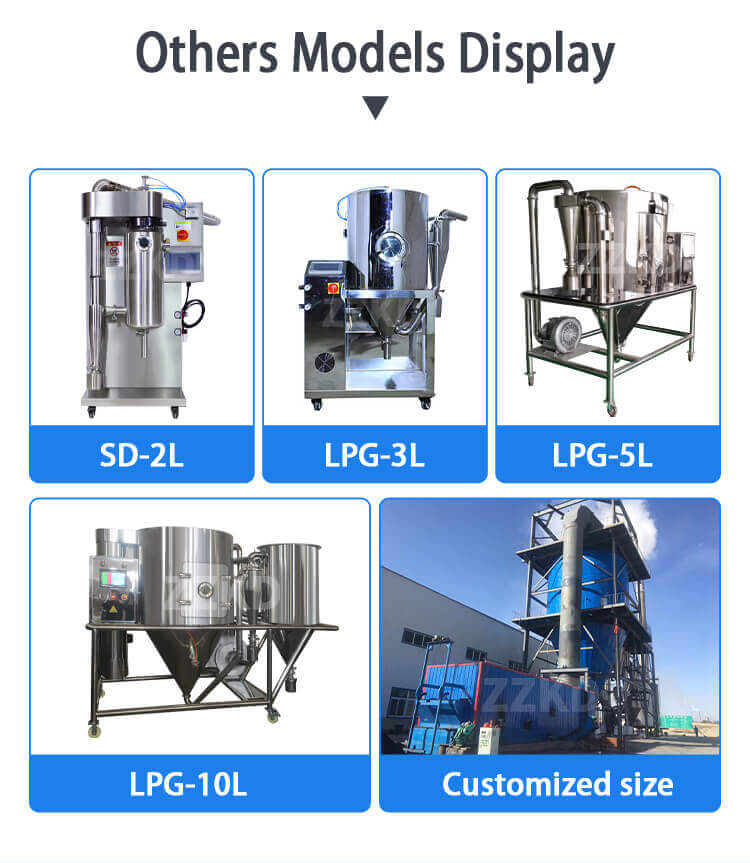

Businesses can assess their requirements based on factors such as the volume of milk to be processed, the desired moisture content of the dried product, and the specific characteristics of the milk-based products to be produced. Commercial Spray Dryer come in various sizes and configurations to accommodate different production volumes and specifications. By evaluating their specific needs and considering factors such as drying capacity, energy efficiency, and product quality, businesses can select the appropriate milk spray dryer model. For example, dairy farms may opt for a smaller-scale dryer for on-site processing, while large-scale dairy manufacturers may require a larger industrial dryer for mass production. These decisions should align with the company’s production goals and quality standards.

What Are the Key Advantages of Investing in a Milk Spray Dryer?

Investing in a milk spray dryer offers several key advantages for businesses. Firstly, it enables efficient and rapid drying of milk into powder form, thereby extending its shelf life and facilitating storage and transportation. Additionally, milk spray dryers allow for precise control over drying parameters, resulting in consistent product quality and uniform particle size distribution. Moreover, these dryers are designed to minimize heat damage and preserve the nutritional content and sensory characteristics of the milk-based products. Ultimately, investing in a milk spray dryer enables businesses to optimize milk processing, enhance product quality, and meet the growing demand for convenient and shelf-stable dairy products in the market.