In the realm of scientific research and industrial processes, the need for high pressure conditions has become increasingly apparent. From understanding fundamental chemical reactions to producing advanced materials and pharmaceuticals, high pressure reactor systems play a crucial role in pushing the boundaries of what is possible. This article delves into the intricacies of high pressure reactor systems, exploring their applications, design principles, safety considerations, and the significant impact they have on various fields of study and industries.

Understanding High Pressure Reactor Systems

High pressure reactor systems are specialized vessels designed to facilitate chemical reactions and processes at elevated pressure levels. These reactors are essential for studying reactions that are highly sensitive to pressure variations, enabling researchers to gain deeper insights into the behavior of substances under extreme conditions. In contrast to conventional atmospheric pressure reactions, high pressure reactions can lead to novel products and provide access to unique reaction pathways.

The primary purpose of employing high pressure reactor systems is to mimic real world conditions, optimize reaction rates, and modify reaction equilibria to achieve desired products. These systems have found applications in diverse fields, such as organic synthesis, catalysis, material science, pharmaceuticals, and petrochemicals.

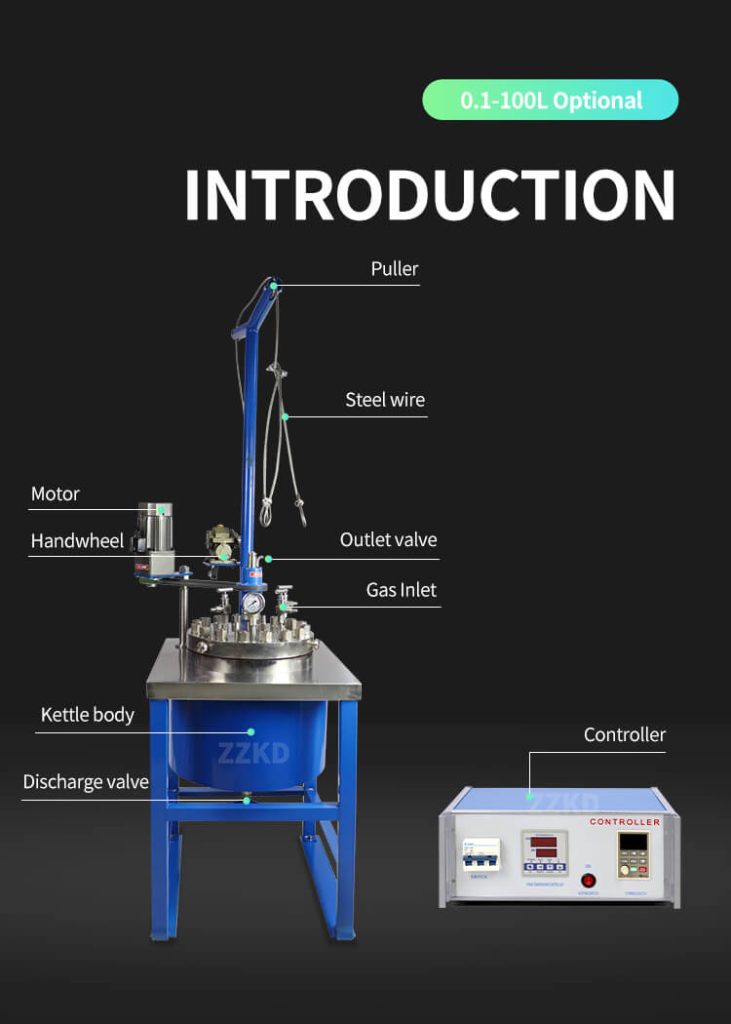

Design and Components of High Pressure Reactor Systems

Engineers meticulously engineer high pressure reactor systems to ensure safety and performance. These systems comprise several essential components that collectively contribute to their successful operation:

1. Pressure Vessel: The heart of the high pressure reactor system is the pressure vessel, which houses the reactants and withstands the elevated pressure. To ensure integrity under extreme conditions, manufacturers typically make pressure vessels from high-strength materials like stainless steel or other alloys.

2. Stirring Mechanism: To ensure uniform mixing and facilitate efficient mass transfer, engineers incorporate a stirring mechanism within the reactor vessel. Commonly used, magnetic stirrers eliminate the need for mechanical seals that could compromise pressure containment.

3. Heating and Cooling System: High pressure reactions often require precise temperature control.The system has heating and cooling to regulate and maintain the desired temperature.

4. Pressure Control System: Engineers integrate a pressure control system to manage and maintain the pressure within the reactor vessel. This system allows researchers to adjust the pressure to the required levels for their experiments.

5. Safety features include pressure relief valves, rupture disks, and pressure interlocks in high pressure reactor systems. These mechanisms protect against over pressurization, reducing the risk of accidents.

6. Modern systems include sensors and instruments to monitor critical parameters like pressure, temperature, and reaction progress. Advanced automation and control systems enable precise and reliable data acquisition.

Applications in Scientific Research of High Pressure Reactor Systems

New avenues in scientific exploration arise from high pressure reactor systems, deepening understanding of reactions and material behaviors. Some key areas where high pressure reactors have made significant contributions include:

1. Organic Synthesis: High pressure conditions can accelerate reactions and influence reaction selectivity, leading to novel products that are otherwise inaccessible. The study of high pressure organic synthesis has enabled the discovery of new pharmaceutical compounds, fine chemicals, and functional materials.

2. Catalysis: High pressure reactors enable researchers to optimize catalytic systems, enhancing industrial processes’ efficiency and selectivity. Understanding catalytic reactions under high pressure has proven essential in fields like petrochemicals and environmental protection.

3. Material Science: High pressure reactor systems have revolutionized material science by enabling the synthesis of advanced materials with unique properties. Researchers have employed high pressure techniques to produce novel superconductors, polymorphs, and high-strength materials.

4. Geochemistry: High pressure studies offer insights into geological processes, like mineral formation and phase transitions in the Earth’s crust.

5. High Pressure Physics: Advancing high pressure physics, these systems explore exotic states of matter and material behavior under extreme pressures.

Industrial Applications

Beyond scientific research, high pressure reactor systems have become indispensable tools in various industries, where they offer substantial benefits in terms of process efficiency and product quality:

1. Petrochemical Industry: High pressure reactors are utilized in the petrochemical industry for processes like hydrocracking and hydrotreating, which convert crude oil fractions into valuable products like gasoline, diesel, and other refined fuels.

2. Pharmaceutical Industry: High pressure reactions are employed in pharmaceutical manufacturing to produce active pharmaceutical ingredients (APIs) and enhance the efficiency of drug synthesis.

3. Food Processing: In food processing, high pressure reactor systems are used for sterilization and pasteurization processes, effectively preserving food products and extending their shelf life.

4. Polymer Industry: High pressure polymerization reactions are crucial in the production of various plastics and elastomers, where control over reaction conditions is essential to achieving desired material properties.

5. Environmental Applications: Environmental Applications: High pressure reactors are used in environmental engineering to study waste treatment processes and explore sustainable energy sources, such as converting biomass into biofuels.

Safety Considerations of High Pressure Reactor Systems

Working with high pressure reactor systems requires strict adherence to safety protocols. The potential hazards associated with high pressure reactions demand meticulous planning, well trained personnel, and robust safety measures.

Pressure vessels should be regularly inspected and certified to ensure their structural integrity. Proper maintenance of seals, gaskets, and safety valves is crucial to avoid leakage and over pressurization incidents.

Operators must be knowledgeable about the specific chemicals and reactions they are handling. In case of accidents or pressure-related incidents, personnel should undergo training in emergency response procedures.

Furthermore, remote monitoring and automated control systems play a vital role in reducing the need for human intervention during high pressure experiments, minimizing potential risks to researchers.

High pressure reactor systems represent an indispensable toolset for advancing the frontiers of science and industry alike. From enabling groundbreaking scientific discoveries to enhancing industrial processes, these systems have broad applications across multiple fields. As technology continues to advance, high pressure reactor systems will undoubtedly play an increasingly significant role in shaping our understanding of chemical reactions and driving innovation in various industries. It is essential to continue exploring safer and more efficient ways to harness the potential of high pressure conditions, unlocking the secrets of matter under extreme circumstances and propelling us towards a brighter and more sustainable future.