Glass reactors have long been a staple in chemical laboratories, offering a controlled environment for various processes. Over time, these reactors have evolved, and multi purpose glass reactors have emerged as a preferred choice for researchers and professionals. With their unique design and versatile functionality, these reactors have proven to be indispensable tools in modern laboratories and industrial settings. In this article, we will explore the benefits and applications of multi purpose glass reactors, helping you make an informed decision when considering to buy one.

Understanding Multi Purpose Glass Reactors

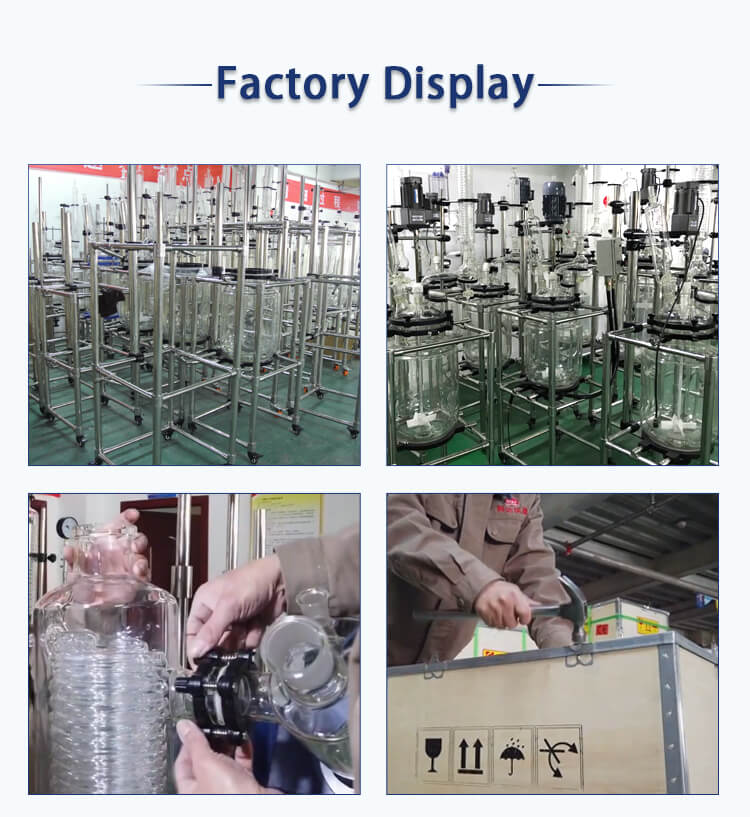

Before diving into the applications and advantages, let’s take a closer look at what multi purpose glass reactors are. These reactors are versatile vessels made of high-quality borosilicate glass that can withstand various chemical reactions. They come equipped with multiple ports and connectors, allowing researchers to perform different types of processes within the same apparatus.

Multi purpose glass reactors are highly adaptable vessels designed to facilitate a diverse range of chemical reactions. Crafted from durable borosilicate glass, these reactors endure diverse conditions, serving as essential tools in labs and industries.

The hallmark of multi purpose glass reactor lies in their ability to accommodate different processes within a single apparatus. Equipped with multiple ports and connectors, researchers can perform stirring, distillation, reflux, crystallization, and more, all in one versatile vessel. It saves time, effort, and reduces setups, minimizing contamination risk.

Temperature control is paramount in chemical reactions, and multi purpose glass reactor excel in this aspect. They come equipped with advanced heating and cooling systems, ensuring accurate and consistent temperature regulation. This level of control is essential, especially for delicate or temperature-sensitive reactions.

In conclusion, multi purpose glass reactors are versatile and efficient tools that have revolutionized chemical processes in laboratories and industries alike. Their versatility in handling diverse reactions, precise temperature control, transparency, and safety features empower researchers in chemistry and innovation.

Applications of Multi Purpose Glass Reactors

The flexibility of multi purpose glass reactors opens up a wide range of applications across different industries. In the pharmaceutical sector, these reactors find extensive use in drug synthesis, crystallization, and process optimization.

In the pharmaceutical sector, multi purpose glass reactors play a crucial role in drug synthesis and development. Researchers harness the reactors’ capabilities to execute complex chemical reactions necessary for producing pharmaceutical compounds. The precise temperature control and efficient mixing provided by these reactors enable the synthesis of high-purity drugs with optimized yields. This has led to the creation of potential life-saving medications and treatments, impacting the well-being of individuals worldwide.

The agrochemical industry also benefits from multi purpose glass reactor in the development of pesticides and fertilizers. These reactors enable researchers to synthesize and optimize chemical compounds with precise control over reaction parameters. Performing multiple processes in one vessel boosts workflow efficiency, speeding up agrochemical product development for improved crop yield and protection.

In the field of nanotechnology, multi purpose glass reactors serve as a powerful tool for the synthesis of nanoparticles and nanomaterials. Researchers can precisely control reaction conditions to achieve desired particle sizes and properties. The reactors’ capability to accommodate multiple processes in a single setup allows for efficient experimentation and the production of innovative nanomaterials with a broad range of applications, including in medicine, electronics, and environmental remediation.

Application Case: Pharmaceutical Compound Synthesis

A pharmaceutical research team was working on synthesizing a complex organic compound for a potential life-saving drug. The team needed a reactor that could handle both the exothermic and endothermic steps of the synthesis process, without the risk of contamination. They chose a multi-purpose glass reactor for its controlled environment and adaptability to various reaction conditions.

The team accomplished the synthesis process in the multi-purpose reactor, utilizing precise temperature control and efficient mixing. The final product achieved high yield and purity, paving the way for further testing and drug development.

In conclusion, multi purpose glass reactors have carved a niche for themselves in various industries and academic research. Their diverse applications span drug synthesis, chemical engineering, agrochemical development, nanotechnology, and fundamental research. With their exceptional capabilities, these reactors continue to revolutionize chemical processes, driving innovation and contributing to significant advancements across a spectrum of scientific disciplines.

Advantages of Multi Purpose Glass Reactors

3.1 Enhanced Efficiency: Multi purpose glass reactors allow multiple reactions in one vessel, saving time and effort in set-up and cleaning.

3.2 Precise Temperature Control: These reactors feature advanced heating and cooling systems, ensuring precise and consistent temperatures during reactions..

3.3 Easy Monitoring: The transparent nature of borosilicate glass enables real-time observation of reactions, facilitating better monitoring and control.

3.4 Versatility: Can be adapted for various processes, such as stirring, distillation, reflux, and more, making them indispensable tools in any chemical laboratory.

Factors to Consider When Buying Multi Purpose Glass Reactors

4.1 Size and Capacity: Choose a reactor size that aligns with your experimental requirements, considering factors like batch size and available laboratory space.

4.2 Material Quality: Ensure the glass reactor is made of high-quality borosilicate glass to withstand the demands of different chemical reactions and prevent contamination.

4.3 Port and Connector Configuration: Evaluate the number and size of ports and connectors on the reactor to ensure they meet the needs of your specific applications.

4.4 Temperature Control System: Check for the type of heating and cooling system the reactor offers, as precise temperature control is crucial for successful reactions.

4.5 Stirring Mechanism: Evaluate the efficiency and design of the stirring mechanism. A well-designed stirring system ensures uniform mixing and enhances reaction kinetics.

4.6 Safety Features: Prioritize reactors equipped with safety features, such as pressure relief valves and temperature alarms, to minimize the risk of accidents during experiments.

Transitioning Towards Sustainable Chemistry

As the world grapples with environmental challenges, the scientific community is increasingly emphasizing sustainable practices in research and development. Multi purpose glass reactors play a crucial role in this transition towards sustainable chemistry. By streamlining processes and reducing waste, researchers contribute to a greener and more efficient future.

The benefits of sustainable chemistry go beyond environmental concerns. Adopting environmentally friendly practices can lead to cost savings and improved reputation for companies. Moreover, by optimizing reactions and minimizing waste generation, researchers can achieve higher yields and reduce the consumption of costly reagents.

The glass reactors enable scientists to explore novel pathways and design more eco-friendly processes. They empower researchers to conduct experiments under precise conditions, helping them identify the most efficient and environmentally responsible reactions.

In recent years, various industries have made significant strides in adopting greener technologies, and the chemical sector is no exception. Sustainable chemistry is driving innovations that promote resource efficiency, reduce pollution, and contribute to the circular economy.

Unlocking the Potential of Multi Purpose Glass Reactors

In the ever-changing landscape of chemical research and development, multi purpose glass reactors have emerged as indispensable tools for efficient and versatile experiments. With their ability to handle various processes within a single apparatus, they save time, resources, and space while promoting sustainable chemistry practices.

When considering to buy a multi-purpose glass reactor, it is essential to assess the reactor’s size, capacity, material quality, temperature control, stirring mechanism, safety features, and other specifications to match your experimental requirements. By making an informed decision, you can invest in a reactor that will streamline your research, enhance productivity, and contribute to a greener future.

As technology continues to advance, multi purpose glass reactors will likely evolve further, integrating automation, advanced sensors, and modular design, among other innovations. These developments will open up new horizons for research, enabling scientists to tackle complex challenges and contribute to groundbreaking discoveries.

In conclusion, the decision to buy multi purpose glass reactors is more than an investment in laboratory equipment; it is an investment in the progress of science and the future of sustainable chemistry. As these reactors continue to evolve and empower researchers worldwide, the possibilities for scientific innovation are boundless.

Whether you are a pharmaceutical researcher, a chemical engineer, or a dedicated scientist, a multi-purpose glass reactor is an invaluable asset that will propel your work to new heights of efficiency and versatility. Embrace the potential of multi purpose glass reactors, and embark on a journey of scientific discovery and progress.