Solvent Recycling System Introduction

An 80L solvent recycling system is a machine designed to recycle and reclaim solvents used in various industrial processes. The system operates by separating the solvent from the contaminants and impurities, thus creating a purified solvent that can be reused in the production process.

Solvent Recycling System Features:

High-efficiency distillation process:

Our Solvent Recycling System utilizes an advanced distillation process that can recover up to 99% of solvents from waste streams.

High-quality and pure recovered solvents:

Our machine is designed to be efficient, ensuring that recovered solvents are of high quality and purity, making them suitable for immediate reuse in various industrial processes.

Cost-effective:

By recycling solvents, businesses can significantly reduce their solvent consumption and waste disposal costs, making it a cost-effective solution for businesses of all sizes.

Eco-friendly:

Our Solvent Recycling System is an eco-friendly alternative to traditional solvent disposal methods, helping businesses reduce their carbon footprint and comply with environmental regulations.

Easy to use:

Our machine is designed to be user-friendly, with an intuitive interface that allows for easy operation and maintenance.

Customizable solutions:

Our Solvent Recycling System can be customized to meet the specific needs of businesses, including different sizes, configurations, and automation levels.

Solvent Recycling System Application:

Laboratories:

Our 80L Solvent Recycling System is ideal for laboratories that use solvents for cleaning or other industrial processes. By recycling solvents, laboratories can reduce their solvent consumption and waste disposal costs.

Printing industry:

Our system can recover solvents used in the printing process, allowing businesses to reuse them and reduce their solvent consumption and disposal costs.

Pharmaceutical industry:

Our system can recover solvents used in the manufacturing of pharmaceutical products, reducing waste and disposal costs for businesses.

Automotive industry:

Our system can recover solvents used in the manufacturing of automotive parts and components, reducing waste and disposal costs for businesses.

Aerospace industry:

Our system can recover solvents used in the aerospace industry for cleaning and other industrial processes, reducing waste and disposal costs for businesses.

Electronics industry:

Our system can recover solvents used in the manufacturing of electronic components, reducing waste and disposal costs for businesses.

Paint and coating industry:

Our 80L Solvent Recycling System is also ideal for the paint and coating industry, where it can effectively recover solvents used in the manufacturing of paints, coatings, and varnishes.

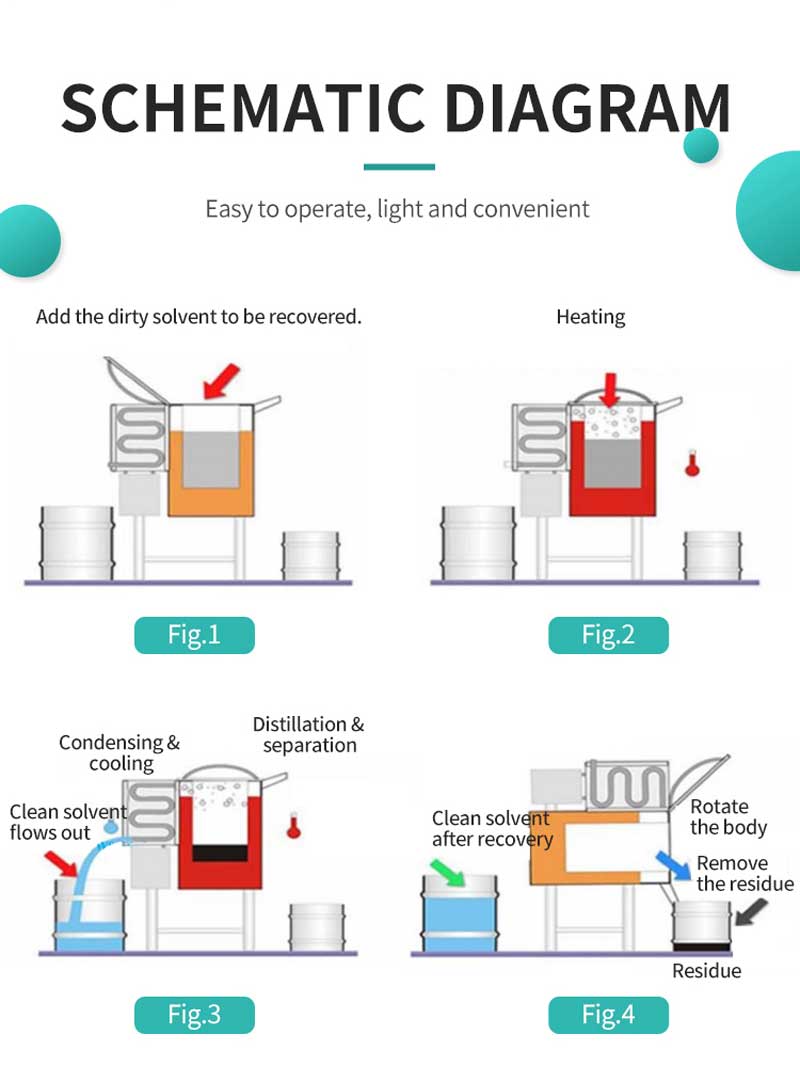

Operating Instructions:

Step 1: check before starting up

Check whether the steam pipeline is blocked or leaking, check the heat medium oil exhaust valve: the open state of the heat medium oil exhaust valve, check the solvent container, check that the solvent outflow pipe is connected to the inlet of the vacuum pump, and the inlet valve of the decompression device is open state.

Step 2: Addition of spent solution (feed/feed)

Add the waste solution that needs to be recovered, and the maximum liquid level line should not be exceeded (if the solvent foams, the feeding capacity must be reduced and the waste solution must not be poured into the steam outlet pipe in the barrel).

Step 3:

machine operation parameter debugging

Step 4: Power On and Off

Power on: Rotate the power knob on the electric control box to point to the “close”/”ON” position, turn on the power, the power indicator light is on, the display screen is running normally, and the machine enters the standby state.

Shutdown: After the system automatically stops running, the cooling fan will automatically stop running; turn the “power switch” to the “on”/”off” position to turn off the power.

Step 5:

Machine operation management

Step 6: Shut down and clean up the residue

After recycling, there will be residue in the recycling bin. The residue must be cleaned up after recycling to avoid drying out the bottom of the drum!

Case Of Solvent Recycling System:

In the PCB and SMT industries, organic solvents such as screen washing water, board washing water, and absolute ethanol (industrial alcohol) are used as cleaning agents to clean equipment and workpieces during the manufacturing process, so a large amount of organic solvent waste will be generated. The traditional waste solvent treatment method is to collect the waste solvent, pile it up in a designated location, and spend money every month to find an environmental protection company to dispose of it. This waste solvent treatment method will not only bring safety hazards such as fires caused by the accumulation of waste solvents, but also cause a waste of resources.

The picture shows a state-owned enterprise PCB manufacturing company using Yitai solvent recovery machine to process washing water. The enterprise produces 200 liters of waste solvent every day, and the recovery rate of waste solvent is as high as 83%. Calculated at 8 yuan/liter, a 100-liter solvent recovery machine processes twice a day, which can save the company 1,280 yuan in new solvent procurement costs, and can save the company 33,280 yuan per month (based on 26 working days per month) Please note that the purchase cost of new solvents can save the company 33,280 yuan per month, and the cost of asking the environmental protection company to dispose of waste solvents is not included here.