Paint Thinner Recycler Machine Introduction

T-40Ex paint thinner recycler machine is a specific type of paint thinner recycling equipment that has a capacity of 40 liters. These machines are designed to recycle and reclaim used or contaminated paint thinners on a medium scale.

This size of paint thinner recycler machine is ideal for small to medium-sized businesses that generate a moderate amount of waste paint thinner, such as auto repair shops, painting contractors, and manufacturing plants. The 40L capacity allows for efficient and cost-effective recycling of the solvent, reducing the amount of hazardous waste generated and saving money on purchasing new solvents.

Paint Thinner Recycler Machine Features:

Heating system:

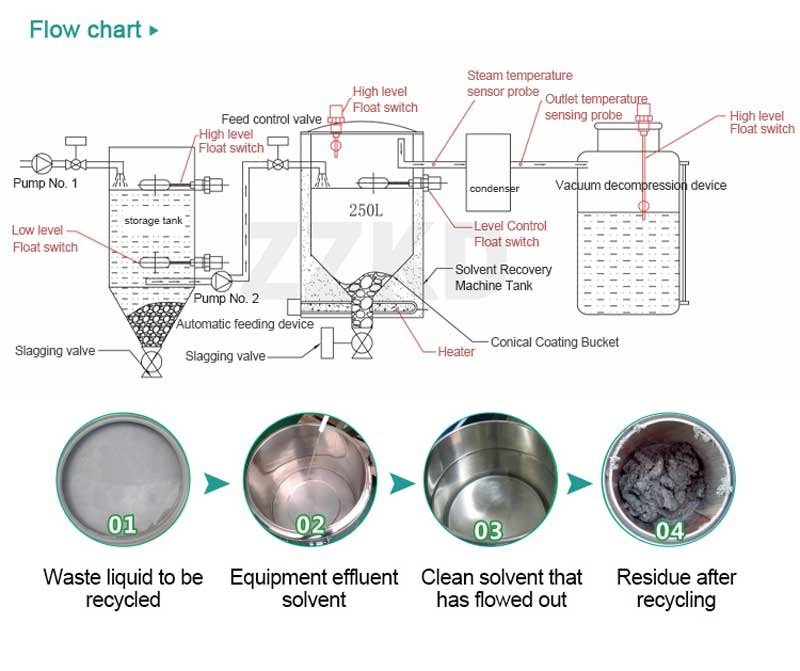

The heating system that heats the contaminated paint thinner and causes it to evaporate.

Condenser:

The condenser that cools the solvent vapors and turns them back into a liquid form.

Filtration system:

The filtration system that removes contaminants and impurities from the paint thinner.

Automatic shut-off:

An automatic shut-off mechanism that turns off the machine when the process is complete, preventing overheating and ensuring safety.

Digital controls:

Digital controls that allow for precise temperature and time settings, making the process more efficient and consistent.

Safety sensors:

Safety sensors that monitor the machine for potential hazards, such as high temperatures or low liquid levels, and trigger an alarm or shut-off if necessary.

Automatic cleaning system:

An automatic cleaning system that cleans the machine after each cycle, ensuring that it is ready for the next use.

Paint Thinner Recycler Machine Application:

Automotive repair shops:

Paint thinner is often used to clean automotive parts and equipment. A paint thinner recycler machine can help automotive repair shops save money by recycling and reusing used or contaminated paint thinners instead of purchasing new solvents.

Painting contractors:

Painting contractors use paint thinners to clean brushes, rollers, and other painting equipment. A paint thinner recycler machine can help contractors reduce waste and save money by recycling used paint thinners instead of disposing of them as hazardous waste.

Manufacturing plants:

Manufacturing plants often use paint thinners in their production processes. A paint thinner recycler machine can help these plants save money by recycling and reusing used paint thinners instead of disposing of them as hazardous waste.

Print shops:

Print shops use solvents to clean printing equipment. A paint thinner recycler machine can help print shops reduce waste and save money by recycling used solvents instead of disposing of them as hazardous waste.

Cleaning services:

Cleaning services often use solvents to clean surfaces and equipment. A paint thinner recycler machine can help these services save money by recycling and reusing used solvents instead of disposing of them as hazardous waste.

Case Of Paint Thinner Recycler Machine:

ABC Car Repair is a small car repair shop that specializes in providing repair services to local customers. The shop uses paint thinners to clean automotive parts and equipment. Previously, the shop used to dispose of used paint thinners as hazardous waste, which was both costly and environmentally unfriendly.

The shop’s owner decided to invest in a paint thinner recycler machine to reduce waste and save costs. The shop purchased a 40L paint thinner recycler machine with digital controls and automatic shut-off mechanisms. The machine was easy to use and required minimal training for the staff.

After using the machine for a few weeks, ABC Car Repair noticed several positive outcomes. Firstly, the shop saved money on purchasing new solvents since the machine recycled and reclaimed used or contaminated paint thinners. The cost savings allowed the shop to reduce its operating expenses and improve its profit margins.

Secondly, the shop reduced the amount of hazardous waste generated, which helped to improve its environmental sustainability. The shop was able to comply with environmental regulations and reduce its carbon footprint.

Thirdly, the shop improved the safety of its operations. The machine’s safety sensors and automatic shut-off mechanisms prevented accidents and reduced the risk of fire or explosion.

Finally, the use of the machine improved the overall efficiency of the shop’s operations. The machine could recycle paint thinner quickly and effectively, allowing for a more streamlined and efficient workflow. The staff could focus on repairing cars rather than worrying about hazardous waste disposal.