Small Vacuum Oven Introduction

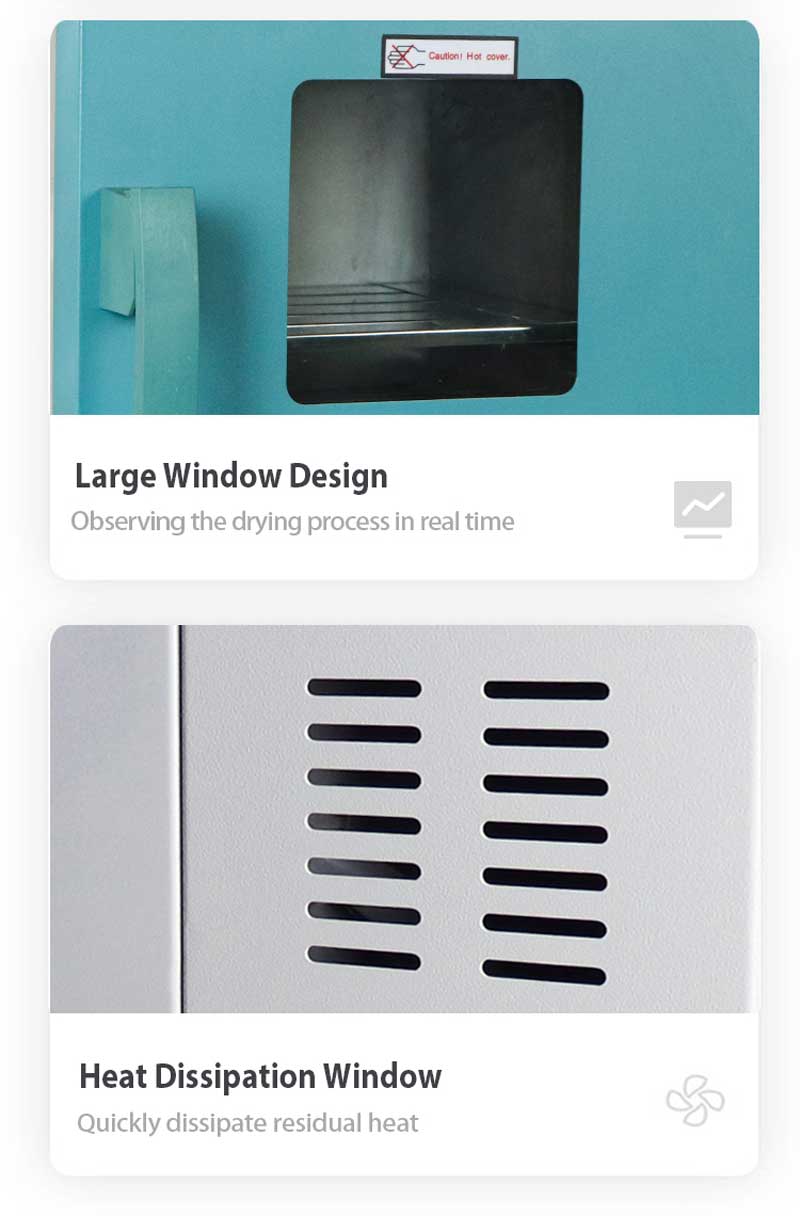

Dzf-6010 small vacuum oven is a mini vacuum oven with a chamber capacity of 8l. Laboratory small vacuum drying ovens are designed for small vacuum drying ovens are usually used for drying and processing small samples. The size of these drying boxes is usually between a few liters and a dozen liters. They are usually equipped with a vacuum pump and a controller that can control the drying process by adjusting the vacuum level and temperature.

Small Vacuum Oven Features:

Vacuum control:

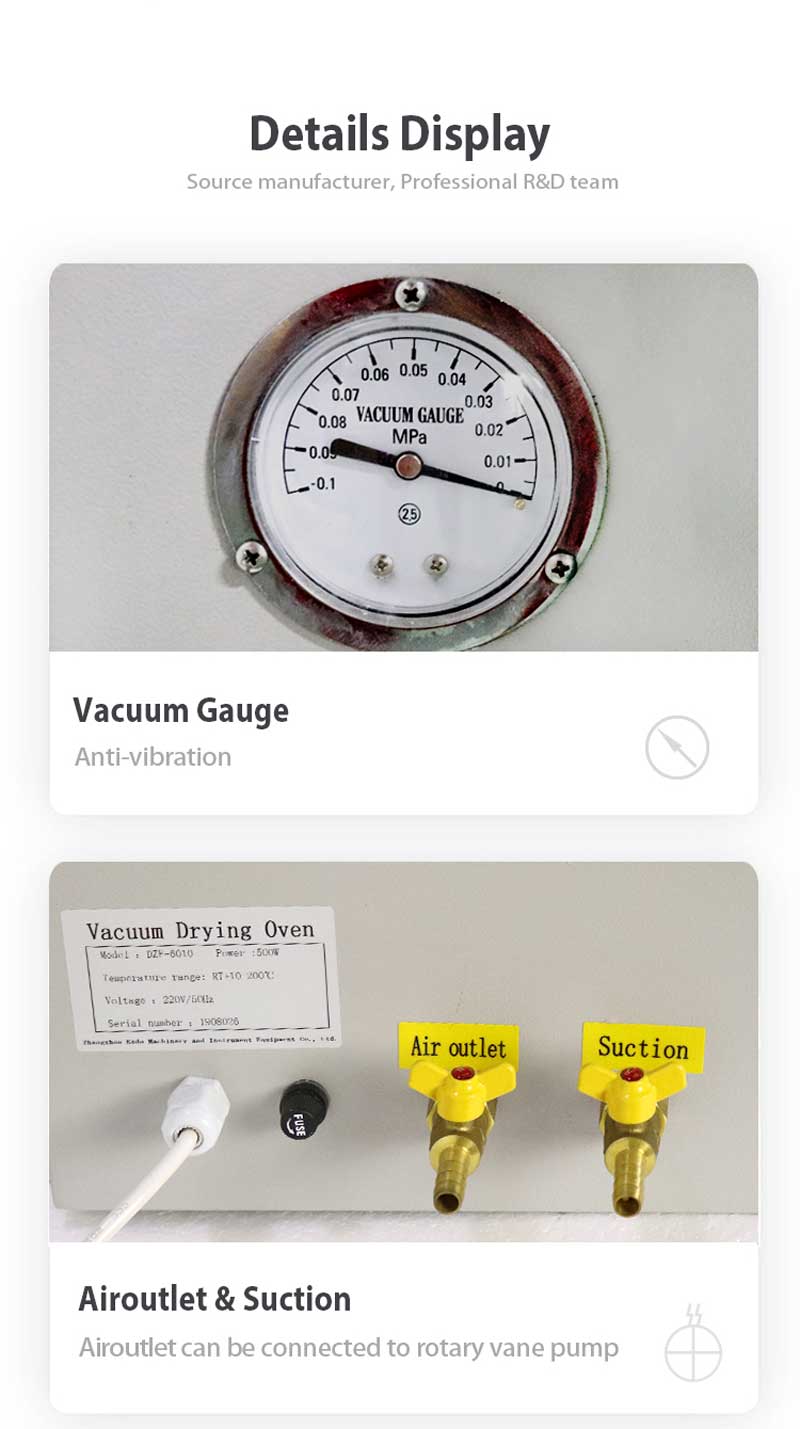

The mini vacuum oven is usually equipped with a vacuum pump and controller, which can control the drying process by adjusting the vacuum level. This increases drying efficiency and quality, and reduces the risk of oxidation or chemical reactions.

Temperature control:

The mini vacuum oven can ensure the drying quality of the sample through precise temperature control. Temperature control can usually be accomplished with a digital controller or an adjustment knob.

Safety:

The small vacuum oven usually has various safety functions, such as overheat protection, overvoltage protection and leakage protection, to ensure that the equipment is safe and reliable during operation.

Displays and alarms:

The small vacuum oven usually has a digital display and an alarm so that the user can monitor the status of the equipment and the drying process at any time.

Energy saving:

Small vacuum ovens often feature energy-saving technologies, such as energy-efficient heating elements and optimized thermal insulation designs, to reduce energy consumption and lower operating costs.

Multifunction:

Some small vacuum ovens are also equipped with other functions, such as circulation and filters, to achieve more applications and experimental needs.

Small Vacuum Oven Application:

Laboratory:

Mini vacuum oven is often used in laboratories, such as experiments in the fields of chemistry, biology, pharmaceuticals, food science, etc., to remove water or other solvents in samples and improve the purity and stability of samples.

Electronic component:

The mini vacuum oven can be used to dry electronic components to remove oxides and moisture on the surface of the components to improve the adhesion, corrosion resistance and stability of the components.

Cellulose products:

Small vacuum oven can be used to dry cellulose products, such as paper, cellulose film and cellulose derivatives, to remove moisture and enhance their mechanical properties.

Food:

Small vacuum oven can be used in the food industry, such as removing or changing moisture, odor and pigment in food to improve the quality and shelf life of food.

Pharmaceutical products:

Small vacuum drying ovens can be used in the pharmaceutical industry, such as drying and processing of drugs to improve the purity and stability of drugs.

Maintenance:>

- The shell of the vacuum box must be effectively grounded or protected to zero to ensure safe use.

- When the vacuum box does not need to be continuously pumped, the vacuum valve should be closed first, and then the power of the vacuum pump should be turned off, otherwise the vacuum pump oil will be poured into the box.

- When taking out the processed items, if the processed items are flammable items, the air must be put in after the temperature is cooled below the ignition point, so as to avoid oxidation reaction and cause combustion.

- There is no explosion-proof device in the vacuum box, and it is not allowed to put explosives into it for drying.

- There is a filter between the vacuum box and the vacuum pump to prevent moisture from entering the vacuum pump.

- When it is not necessary, please do not disassemble the side door at will, so as not to damage the electrical system.

Case Of Small Vacuum Oven:

Small vacuum oven türkiye customer experience

An electronic component manufacturer in turkey needed to dry a small batch of electronic chips, which were prone to oxidation and corrosion during storage. Manufacturers had previously used conventional ovens for drying, but the high temperatures and exposure to air caused the chips to deteriorate over time. Manufacturers decide to invest in our small vacuum ovens to improve the quality and longevity of their products.

The vacuum oven has a chamber volume of 8 liters, a temperature range up to 150°c, and a vacuum range of 0-0.1 mpa. The ovens are equipped with digital controllers and programmable timers, allowing manufacturers to accurately set the temperature and drying time. A vacuum pump ensures that the chip is dry in a low pressure environment, minimizing the contact of the chip with air, preventing oxidation and corrosion.

Manufacturers place electronic chips into a vacuum oven and set the temperature and drying time according to chip specifications. The vacuum pump then removes the air in the room and the oven starts the drying process. After a set time, the oven is automatically turned off and the maker retrieves the dried chips.

Thanks to small vacuum ovens, manufacturers are able to efficiently dry electronic chips without any damage from heat or air exposure. The controlled environment of the vacuum oven provides precise conditions for drying, and the vacuum pump prevents chip oxidation and corrosion, thereby improving the quality and life of the chip. The manufacturer was able to provide its customers with high-quality electronic components, increasing their customer satisfaction and loyalty.