Single stage rotary vane vacuum pump introduction

A single-stage rotary vane vacuum pump is a type of positive displacement pump that is commonly used to create a vacuum in various applications, including in the chemical, pharmaceutical, and automotive industries.

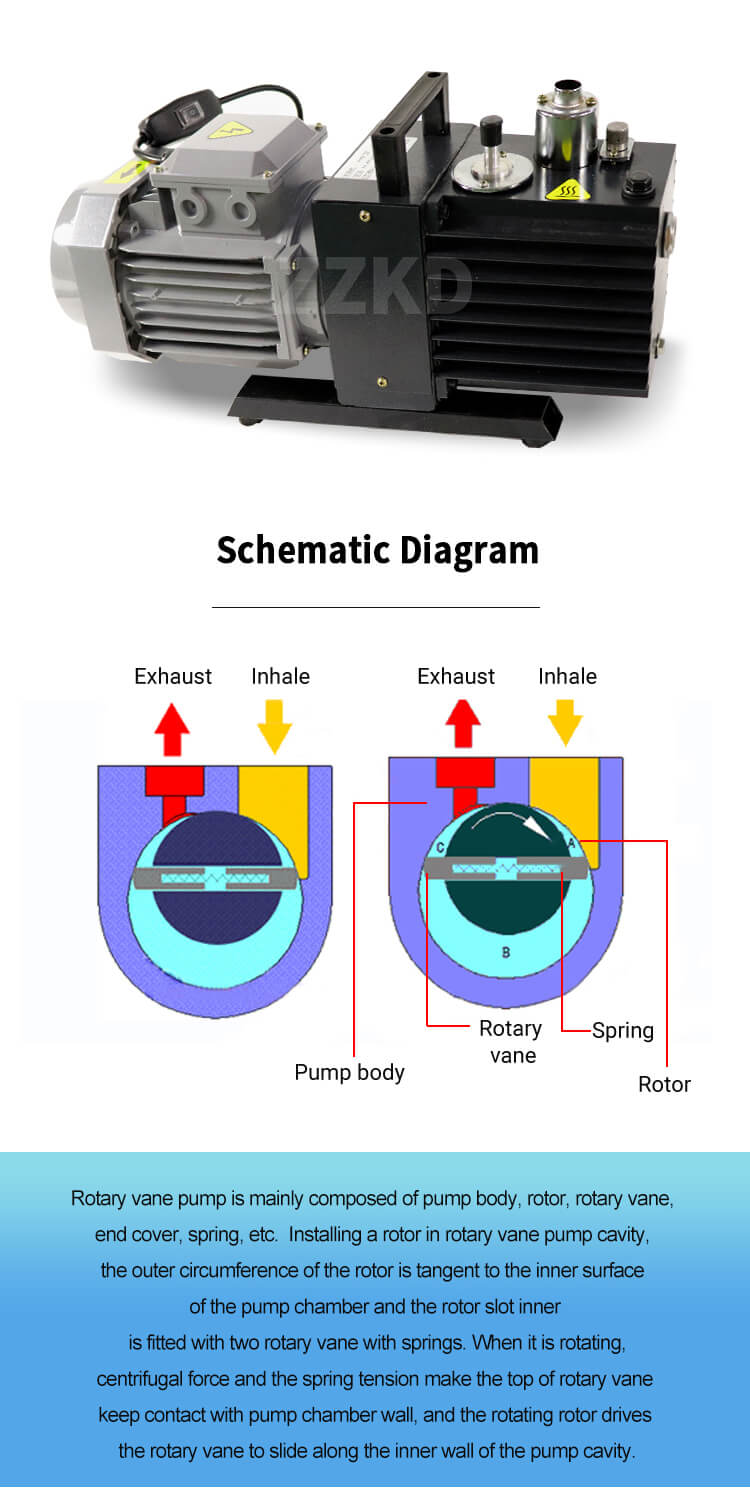

The pump consists of a rotor with several vanes that rotate inside a cylindrical chamber. The vanes are pushed outwards by centrifugal force and create a seal against the chamber wall. As the rotor turns, the vanes trap and compress gas or air, pushing it through an outlet valve and out of the pump. This process repeats continuously, creating a vacuum by removing gas or air from a chamber or system.

Single-stage rotary vane vacuum pumps are known for their simplicity, reliability, and low cost. They are capable of producing vacuum levels of up to 0.1 mbar, making them suitable for many applications. However, they are not suitable for high-vacuum applications, where deeper vacuum levels are required.

Single-stage rotary vane vacuum pumps are commonly used in applications such as vacuum drying, degassing, vacuum packaging, and vacuum distillation. They are also used in laboratory and research settings, where they are used to create vacuum for various experiments and processes.

Single stage rotary vane vacuum pump Features:

Here are some of the main features of a single-stage rotary vane vacuum pump:

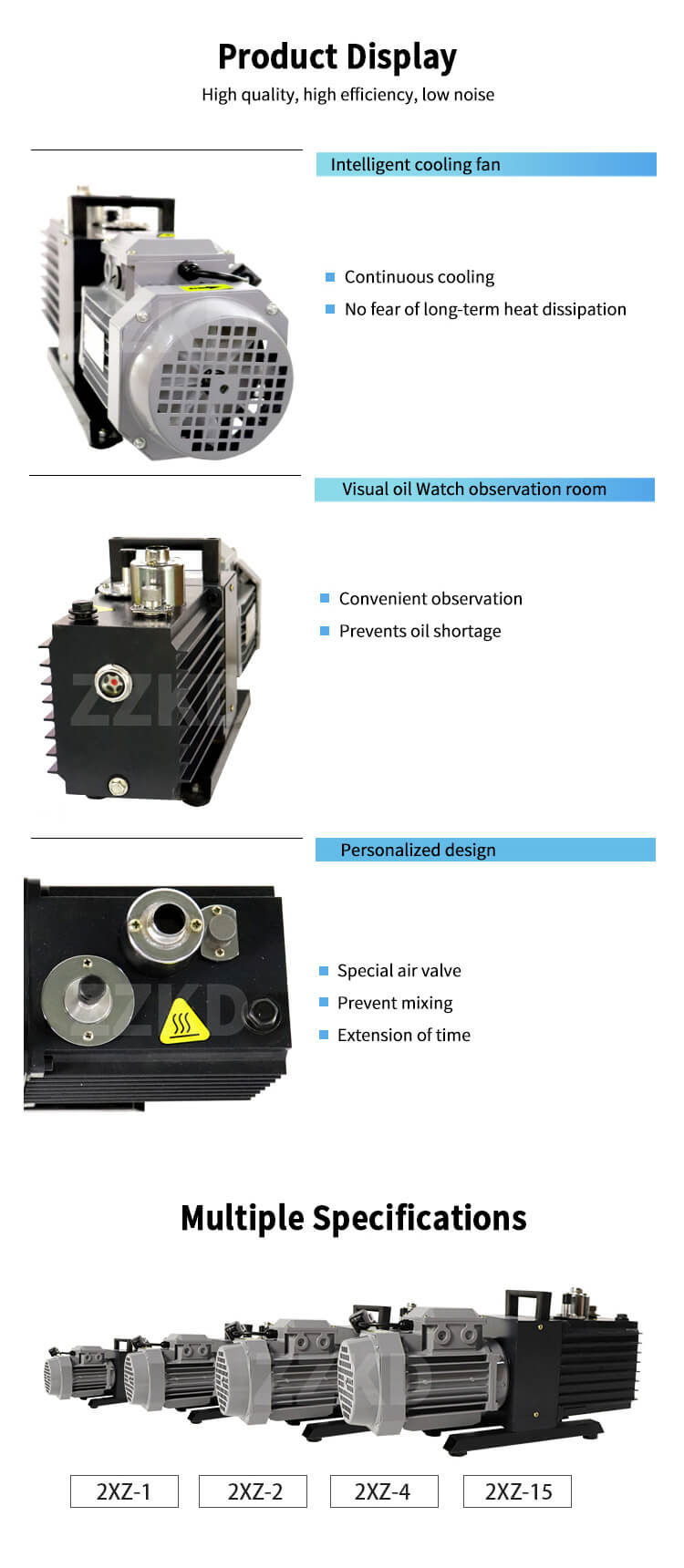

- Simple design: Single-stage rotary vane vacuum pumps have a simple design that is easy to maintain and repair. They consist of a few basic components, including a rotor, vanes, and housing.

- Reliable: Rotary vane pumps are known for their reliability and long service life. They have few moving parts, which reduces the likelihood of mechanical failure.

- Low noise: Single-stage rotary vane pumps operate quietly, making them suitable for use in noise-sensitive environments.

- Low vibration: Rotary vane pumps produce minimal vibration, which reduces the risk of damage to sensitive equipment and instruments.

- Easy to use: These pumps are easy to operate and require minimal training to use. They typically have simple control systems and do not require specialized skills to operate.

- Cost-effective: Single-stage rotary vane pumps are relatively inexpensive compared to other types of vacuum pumps. They are a cost-effective solution for many applications.

- Compact size: These pumps are relatively small and can be easily integrated into existing systems or used as standalone units.

- Oil lubricated: Most single-stage rotary vane pumps are oil lubricated, which helps to reduce wear and tear on the pump components and prolong the service life of the pump.

- Capable of handling a range of gases: These pumps are capable of handling a wide range of gases, including corrosive and explosive gases, making them suitable for many different applications.

Single stage rotary vane vacuum pump Application:

Single-stage rotary vane vacuum pumps are commonly used in a wide range of applications, including:

- Vacuum packaging: These pumps are used to create a vacuum in food packaging to extend the shelf life of perishable products.

- Chemical processing: Rotary vane pumps are used in chemical processing applications to create a vacuum for distillation, filtration, and drying processes.

- Laboratory and research: These pumps are used in laboratory and research settings for experiments and processes that require a vacuum, such as in vacuum ovens, freeze dryers, and electron microscopes.

- Automotive: Single-stage rotary vane pumps are used in automotive applications, such as brake boosters and air conditioning systems.

- HVAC: These pumps are used in heating, ventilation, and air conditioning systems to evacuate air and moisture from the system.

- Semiconductor manufacturing: Rotary vane pumps are used in semiconductor manufacturing for wafer processing, deposition, and ion implantation.

- Printing: These pumps are used in printing applications for the creation of vacuum in paper handling systems.

- Environmental testing: Single-stage rotary vane pumps are used in environmental testing applications to create a vacuum for testing the resistance of products to extreme temperatures and pressures.

- Food processing: These pumps are used in food processing applications for vacuum freeze-drying, extraction, and concentration processes.

Case : ZZKD Company Selling Single stage rotary vane vacuum pump to an American Customer

ZZKD company is a manufacturer of laboratory equipment, including single-stage rotary vane vacuum pumps. Recently, they sold one of their pumps to an American customer who was in need of a reliable vacuum pump for their laboratory experiments.

The customer, a research scientist at a university in the United States, was looking for a vacuum pump that was easy to use and maintain, yet powerful enough to handle a range of applications. They had previously used a different brand of vacuum pump, but were not satisfied with its performance and reliability.

After researching several options, the customer came across ZZKD’s single-stage rotary vane vacuum pump. They were impressed with the pump’s simple design, low noise, and ease of use, and decided to give it a try.

Upon receiving the pump, the customer was pleased with how easy it was to set up and operate. They were able to create a vacuum quickly and easily, and the pump’s low noise and vibration levels were a welcome change from their previous pump.

Over the next few weeks, the customer used the pump for a variety of experiments and processes, including vacuum filtration and distillation. They found that the pump was able to handle these applications with ease, and they appreciated its reliability and consistent performance.

Overall, the customer was very satisfied with their purchase of the ZZKD single-stage rotary vane vacuum pump. They found it to be a reliable and cost-effective solution for their laboratory vacuum needs, and they would not hesitate to recommend it to others.

In conclusion, ZZKD’s single-stage rotary vane vacuum pump proved to be a great fit for this American customer. Its simplicity, reliability, and ease of use made it an ideal choice for their laboratory needs, and the customer was very satisfied with their purchase.