Recirculating chiller heater introduction

A recirculating chiller heater is a type of machine used in scientific and industrial settings to control the temperature of fluids or equipment. It consists of a closed loop system that circulates a fluid, such as water or a specialized coolant, through a heat exchanger to regulate its temperature.

The chiller component of the machine works by removing heat from the fluid through a refrigeration process, while the heater component adds heat back to the fluid as needed to maintain the desired temperature range. This allows the recirculating chiller heater to both cool and heat the fluid, making it a versatile and effective tool for precise temperature control.

Recirculating chiller heaters are commonly used in laboratories, manufacturing facilities, and other industrial settings where accurate temperature control is critical for maintaining equipment and processes. They can be used for a wide range of applications, including cooling lasers, maintaining the temperature of chemical reactions, and regulating the temperature of sensitive materials during manufacturing processes.

Recirculating chiller heater Features:

Recirculating chiller heaters are versatile and sophisticated machines that come with a range of features to ensure precise temperature control and efficient operation. Some common features of recirculating chiller heaters include:

- Temperature range control: Most recirculating chiller heaters have a temperature range control that allows users to set and maintain the desired temperature range.

- Programmable controls: Many models feature programmable controls that enable users to create customized temperature profiles or set specific heating and cooling cycles.

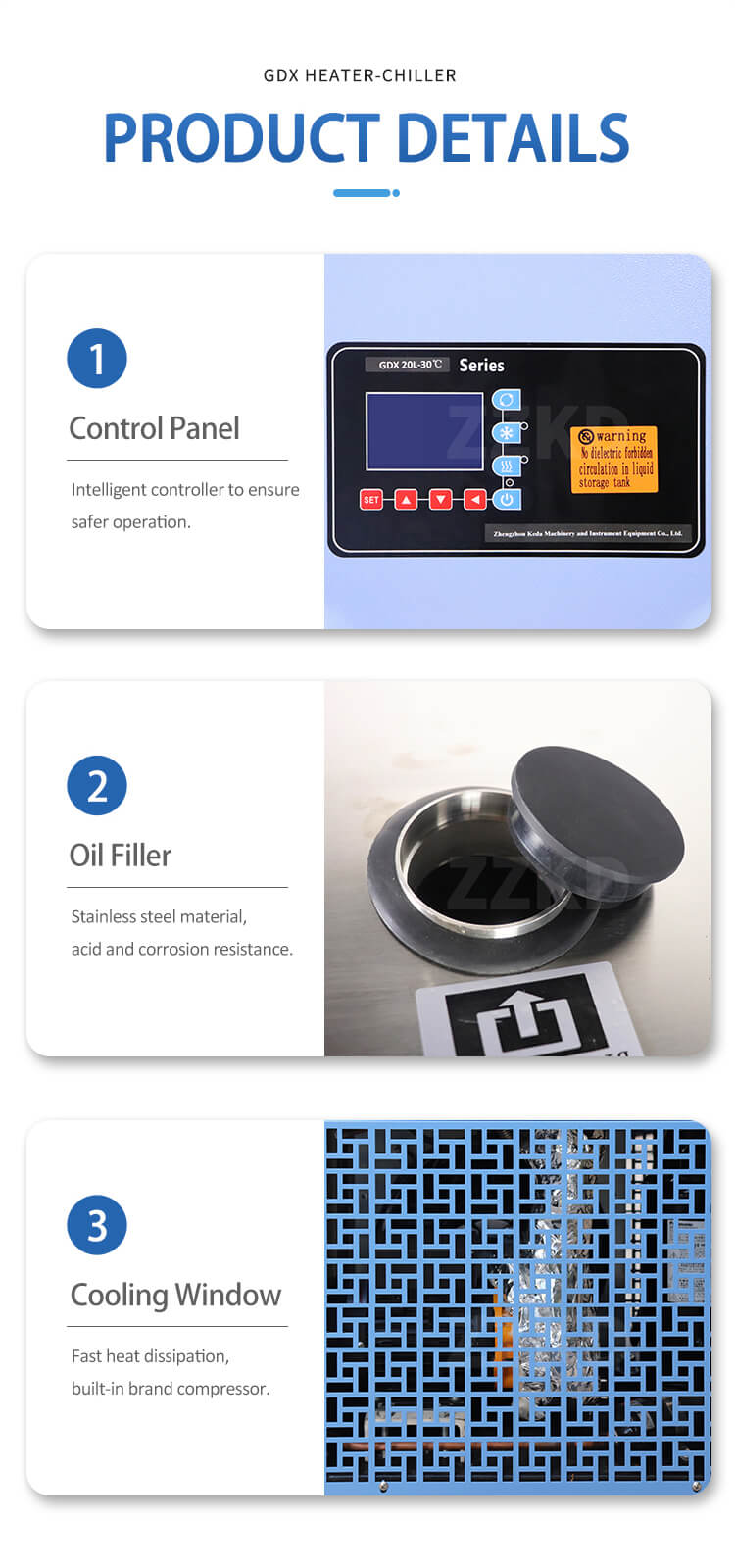

- Digital display: A digital display allows users to monitor the temperature of the fluid in real-time, making it easier to maintain the desired temperature range.

- High cooling capacity: Recirculating chiller heaters are designed to have high cooling capacities, which means they can quickly and effectively remove heat from the fluid, even at high temperatures.

- Compact size: Most models are compact and space-saving, making them ideal for use in laboratories and other settings where space is at a premium.

- Efficient operation: Recirculating chiller heaters are typically designed to be energy-efficient, using advanced cooling and heating technology to minimize energy consumption.

- Low noise level: Many models are designed to operate with low noise levels, making them ideal for use in settings where quiet operation is important.

- Safety features: Recirculating chiller heaters often come with safety features, such as automatic shut-off switches or alarms, to prevent damage to the machine or to the user in case of a malfunction or overheat.

Recirculating chiller heaters are highly advanced and versatile machines that can be tailored to meet the specific needs of a wide range of industrial and scientific applications.

Recirculating chiller heater Application:

Recirculating chiller heaters are used in a wide range of scientific and industrial applications where precise temperature control is required. Some common applications include:

- Laser cooling: High-power lasers generate a lot of heat, and recirculating chiller heaters are used to remove the excess heat to keep the lasers at a stable temperature.

- Chemical reactions: Many chemical reactions require specific temperatures to proceed effectively, and recirculating chiller heaters are used to maintain these temperatures.

- Industrial processes: In manufacturing processes such as semiconductor fabrication or metalworking, recirculating chiller heaters are used to control the temperature of machinery and equipment to ensure high-quality output.

- Medical and pharmaceuticals: In medical and pharmaceutical applications, recirculating chiller heaters are used to control the temperature of chemicals, drugs, or biological samples for research, testing, and storage purposes.

- Analytical instrumentation: Recirculating chiller heaters are also commonly used in analytical instrumentation such as chromatography and spectroscopy equipment, where precise temperature control is crucial for accurate measurements.

- Environmental testing: In environmental testing, recirculating chiller heaters are used to create temperature-controlled environments for testing the durability and reliability of materials and equipment.

- Food and beverage production: In food and beverage production, recirculating chiller heaters are used to control the temperature of ingredients, processing equipment, and storage facilities to ensure food safety and product quality.

Recirculating chiller heaters are essential tools for many industries that require precise temperature control for their processes.

Case : ZZKD Company Selling Recirculating chiller heater to an American Customer

ZZKD is a leading manufacturer and supplier of high-quality recirculating chiller heaters for scientific and industrial applications. Recently, the company had the opportunity to sell their products to a group of American customers, including research laboratories, universities, and manufacturing companies.

The customers were looking for a reliable and efficient solution to control the temperature of their equipment and processes, and they were impressed with the wide range of features and capabilities offered by ZZKD’s recirculating chiller heaters. The machines were also compact and easy to install, which was important for customers with limited space.

After purchasing the recirculating chiller heaters, the customers were pleased with the performance and efficiency of the machines. The digital display made it easy to monitor and adjust the temperature, and the programmable controls allowed them to create customized temperature profiles for their specific applications. The customers also appreciated the energy-efficient design, which helped to reduce their overall energy costs.

One customer, a research laboratory specializing in materials science, commented that the ZZKD recirculating chiller heater had greatly improved their ability to conduct experiments at precise temperatures, resulting in more accurate and reliable data. Another customer, a manufacturing company, noted that the chiller heater had helped them improve the quality and consistency of their products by controlling the temperature of their production equipment.

Overall, the American customers were highly satisfied with the performance and quality of the ZZKD recirculating chiller heaters, and several have recommended the machines to their colleagues in other industries. ZZKD is proud to have provided these customers with reliable and effective solutions for their temperature control needs, and looks forward to continuing to serve customers both in the United States and around the world.