In the world of chemical processing, the choice of equipment plays a crucial role in determining the efficiency, safety, and success of operations. Among the myriad options available, the stainless steel chemical reactor stands out as a superior choice for many applications. This article delves into the reasons why stainless steel reactors are the preferred choice for many industries, exploring their benefits, applications, and the science behind their widespread use.

Durability and Longevity

One of the foremost reasons to opt for a stainless steel reactor is its exceptional durability. Stainless steel is renowned for its robustness and ability to withstand harsh conditions. In chemical processing, where reactions can be highly exothermic and involve corrosive substances, the durability of equipment is paramount. Stainless steel reactors are resistant to corrosion, rust, and chemical reactions, ensuring a long lifespan and reducing the need for frequent replacements.

Corrosion Resistance

Corrosion is a significant concern in the chemical industry, where reactors are exposed to a variety of aggressive chemicals. Stainless steel is inherently resistant to corrosion due to the presence of chromium, which forms a passive layer of chromium oxide on the surface. This layer protects the material from further oxidation and deterioration. This feature is particularly crucial when dealing with acids, bases, and other corrosive substances, making stainless steel reactors ideal for a wide range of chemical processes.

High-Temperature Resistance

Chemical reactions often require high temperatures to proceed efficiently. Stainless steel reactors can withstand extreme temperatures without losing their structural integrity. This high-temperature resistance is vital for maintaining safety and performance in processes that involve heating or cooling cycles. Unlike other materials that may degrade or deform under high temperatures, stainless steel remains stable, ensuring consistent reaction conditions and product quality.

Hygienic and Easy to Clean

In industries such as pharmaceuticals, food processing, and biotechnology, maintaining a sterile environment is critical. Stainless steel’s non-porous surface makes it easy to clean and sanitize, preventing contamination and ensuring product purity. The material does not harbor bacteria or other pathogens, making it an excellent choice for applications where hygiene is paramount. How important is it to ensure cleanliness in your processing environment? With stainless steel reactors, achieving and maintaining high standards of cleanliness is straightforward.

Versatility in Applications

Stainless steel chemical reactors are incredibly versatile and can be used in a wide range of industries. From pharmaceuticals and biotechnology to petrochemicals and food processing, these reactors are capable of handling various substances and reaction conditions. Their versatility is enhanced by the availability of different grades of stainless steel, each tailored to specific applications and environments. For instance, 316L stainless steel is often used in pharmaceutical applications due to its superior corrosion resistance and ease of cleaning.

Cost-Effectiveness

While the initial cost of stainless steel reactors might be higher compared to other materials, their long-term cost-effectiveness is undeniable. The durability, low maintenance requirements, and extended lifespan of stainless steel reactors result in significant cost savings over time. Additionally, the reduced risk of contamination and product loss due to corrosion or equipment failure further enhances their economic viability. Have you considered the long-term savings associated with durable, low-maintenance equipment? Investing in stainless steel reactors can lead to substantial financial benefits in the long run.

Environmental Benefits

In today’s world, sustainability and environmental responsibility are more important than ever. Stainless steel is a recyclable material, meaning that at the end of its life cycle, it can be recycled and repurposed without losing its properties. This recyclability contributes to a reduction in industrial waste and promotes a circular economy. By choosing stainless steel reactors, companies can demonstrate their commitment to sustainability and reduce their environmental footprint.

Superior Strength and Pressure Handling

Chemical reactions can generate high pressures, necessitating reactors that can withstand these conditions without compromising safety. Stainless steel reactors are known for their superior strength and ability to handle high pressures. This attribute is particularly important in reactions that involve gases or volatile compounds, where pressure control is critical. The strength of stainless steel ensures that reactors can operate safely under a wide range of pressures, minimizing the risk of accidents or equipment failure.

Enhanced Safety Features

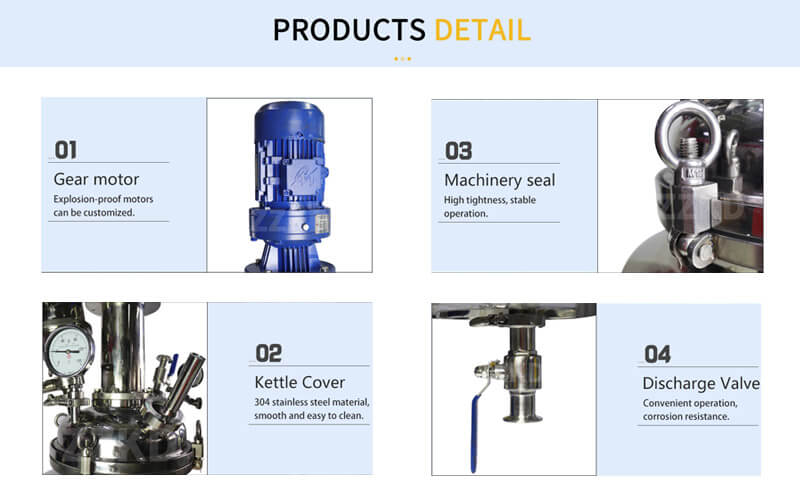

Safety is a top priority in any chemical processing operation. Stainless steel reactors come equipped with various safety features that enhance operational safety. For example, they often include pressure relief valves, temperature monitoring systems, and robust sealing mechanisms to prevent leaks. These features work together to ensure that the reactor operates within safe parameters, protecting both personnel and the environment. How much emphasis do you place on safety in your operations? With stainless steel reactors, you can enhance the safety of your processes and ensure compliance with industry regulations.

Customizability and Scalability

Every chemical process is unique, requiring equipment that can be tailored to specific needs. Stainless steel reactors offer a high degree of customizability, allowing manufacturers to design reactors that meet precise specifications. Whether it’s the size, shape, or additional features like agitation systems and heat exchangers, stainless steel reactors can be customized to fit the exact requirements of a process. Additionally, these reactors are scalable, making it easy to expand operations as demand grows. This flexibility makes stainless steel reactors an excellent choice for both small-scale research and large-scale industrial production.

Improved Product Quality

The quality of the final product is directly influenced by the materials and equipment used in the manufacturing process. Stainless steel reactors contribute to improved product quality by providing a stable, contamination-free environment for chemical reactions. The material’s resistance to corrosion and leaching ensures that no impurities are introduced into the reaction, resulting in higher purity and consistency of the final product. In industries where product quality is paramount, such as pharmaceuticals and food processing, this advantage is particularly significant.

The benefits of using a stainless steel chemical reactor are numerous and far-reaching. From their exceptional durability and corrosion resistance to their high-temperature handling and ease of cleaning, stainless steel reactors offer unparalleled advantages in a wide range of applications. Their cost-effectiveness, environmental benefits, and superior safety features make them an ideal choice for industries committed to quality, efficiency, and sustainability.

Have you evaluated the benefits of stainless steel reactors for your operations? If you haven’t yet, it might be time to consider making the switch. The investment in stainless steel reactors can lead to significant improvements in process efficiency, product quality, and overall operational safety.

Whether you’re in pharmaceuticals, food processing, petrochemicals, or any other industry that requires reliable and efficient chemical processing equipment, stainless steel reactors are a tried and true choice. Their versatility, customizability, and scalability ensure that they can meet the unique demands of any application, providing a solid foundation for successful chemical processing.

By choosing stainless steel reactors, you’re not just investing in equipment; you’re investing in the future of your operations, ensuring that they remain competitive, sustainable, and capable of delivering high-quality products to meet the demands of a dynamic market.