In the fast-paced world of pharmaceutical and nutraceutical production, the demand for efficient, reliable, and high-quality tablet manufacturing solutions is ever-growing. Enter the rotary tablet press machine, a marvel of engineering that combines speed, precision, and versatility to meet the rigorous demands of modern production. But what exactly makes the rotary tablet press machine a game-changer in the industry? Let’s explore its features, benefits, and how it can revolutionize your manufacturing process.

What is a Rotary Tablet Press Machine?

A rotary tablet press machine, also known as a rotary tablet compression machine, is a mechanical device used to compress powder or granular material into tablets of uniform size and weight. It operates by pressing the material between two punches and a die, a process repeated rapidly to produce tablets in large quantities. The rotary tablet press machine is widely used in the pharmaceutical, nutraceutical, and confectionery industries.

The Advantages of a Rotary Tablet Press Machine

High Efficiency and Productivity

One of the most significant advantages of a rotary tablet press machine is its high efficiency. The machine is designed to produce large quantities of tablets quickly, with some models capable of manufacturing thousands of tablets per minute. This high throughput makes it an ideal choice for large-scale production facilities that need to meet high demand.

How pharmaceutical companies manage to produce millions of tablets with consistent quality?

The rotary tablet press machine is the answer. Its ability to maintain a high production rate without compromising on quality is a testament to its advanced engineering.

Consistent Quality and Precision

In the pharmaceutical industry, consistency and precision are paramount. The rotary tablet press machine ensures that each tablet produced is of uniform size, weight, and composition. This consistency is achieved through precise control over the compression process, ensuring that each tablet meets stringent quality standards.

Versatility in Tablet Production

Rotary tablet press machines are incredibly versatile, capable of producing tablets of various shapes, sizes, and compositions. Whether you need round, oval, or custom-shaped tablets, this machine can handle it. Additionally, it can accommodate different formulations, including those with multiple layers or special coatings.

Cost-Effective Operation

Despite the high initial investment, rotary tablet press machines are cost-effective in the long run. Their high production capacity and low maintenance requirements result in reduced operational costs. Furthermore, their efficiency and reliability minimize downtime, ensuring a steady production flow and maximizing return on investment.

Enhanced Safety Features

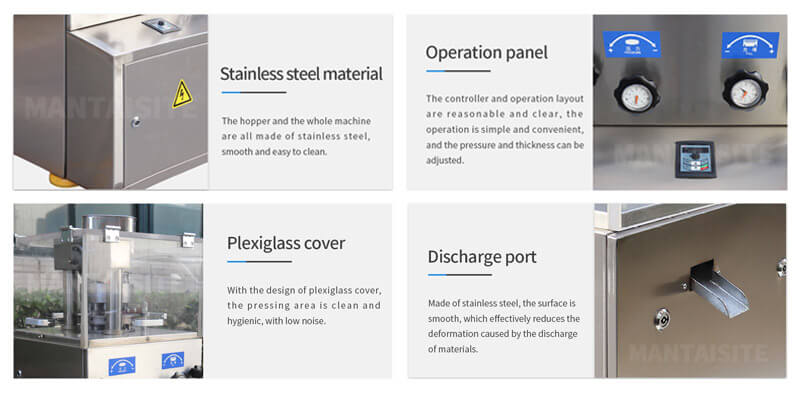

Modern rotary tablet press machines are equipped with advanced safety features to protect both the operator and the machine. These features include automatic shut-off systems, overload protection, and enclosed designs to prevent contamination. These safety measures are crucial in maintaining a safe and compliant production environment.

Key Components of a Rotary Tablet Press Machine

To understand how a rotary tablet press machine operates, it’s essential to familiarize yourself with its key components:

Hopper: Holds the powder or granulate to be compressed into tablets.

Feeder: Directs the material from the hopper into the die.

Die: Determines the size and shape of the tablet.

Upper and Lower Punches: Compress the material within the die to form a tablet.

Turret: Houses multiple sets of dies and punches, rotating to position each set for the compression process.

Cam Tracks: Guide the punches through the compression cycle.

How Does a Rotary Tablet Press Machine Work?

The operation of a rotary tablet press machine involves several steps:

1. Filling: The material is fed from the hopper into the die cavity.

2. Compression: The upper and lower punches compress the material within the die, forming a tablet.

3. Ejection: The finished tablet is ejected from the die and collected.

4. Rotation: The turret rotates to position the next set of dies and punches for compression.

This cycle is repeated rapidly, allowing for continuous and high-speed tablet production.

Addressing Common Concerns

What about the initial cost?

While the initial cost of a rotary tablet press machine can be substantial, it is important to consider the long-term benefits. The machine’s high production capacity, efficiency, and low maintenance requirements result in significant cost savings over time. For businesses focused on large-scale production, the return on investment is substantial.

How do I ensure consistent quality?

Ensuring consistent quality with a rotary tablet press machine involves regular maintenance, calibration, and adherence to operating protocols. Many modern machines come with automated systems that monitor and adjust the compression process in real-time, ensuring that each tablet meets quality standards. Additionally, investing in training for your operators can further enhance the reliability and consistency of your production.

Real-World Applications

Pharmaceutical Industry

In the pharmaceutical industry, rotary tablet press machines are indispensable. They are used to produce a wide range of medications, from over-the-counter pain relievers to prescription drugs. The ability to produce tablets with precise dosages and uniform quality is crucial for patient safety and regulatory compliance.

Nutraceutical Industry

The nutraceutical industry also benefits significantly from rotary tablet press machines. These machines are used to produce vitamins, supplements, and other health products. The versatility of the machine allows manufacturers to create tablets with various formulations and custom shapes, catering to consumer preferences and market trends.

Confectionery Industry

In the confectionery industry, rotary tablet press machines are used to produce candies and mints. The high-speed production capabilities and ability to create various shapes make these machines ideal for meeting the demands of this fast-moving market.

| Model | ZP-5A | ZP-7A | ZP-9A |

| Punch quantity (Sets) | 5 | 7 | 9 |

| Max.tablet pressure (kn) | 40 | 60 | 60 |

| Max.tablet diameter (mm) | 20 | 20 | 20 |

| Max.filling depth (mm) | 15 | 15 | 15 |

| Max.tablet thickness (mm) | 6 | 6 | 6 |

| Turret rotary speed (r/min) | 30 | 30 | 30 |

| Production capacity (PC/h) | 9000 | 12600 | 16200 |

| Motor power (kw) | 1.5 | 1.5 | 1.5 |

| Overall size (mm) | 400×580×1000 | 400×580×1000 | 400×580×1000 |

| Machine weight (kg) | 190 | 190 | 190 |

The rotary tablet press machine is a powerhouse in the world of tablet manufacturing. Its high efficiency, consistent quality, versatility, and cost-effectiveness make it an essential tool for businesses in the pharmaceutical, nutraceutical, and confectionery industries. By investing in a rotary tablet press machine, you can enhance your production capabilities, meet high demand, and ensure that your products consistently meet the highest quality standards.

Are you ready to take your tablet manufacturing process to the next level? Consider the rotary tablet press machine – a reliable and efficient solution that can revolutionize your production and help you stay ahead in a competitive market. Whether you’re producing life-saving medications, health-boosting supplements, or delightful confections, this machine offers the precision and performance you need to succeed.