High pressure reactors stand at the forefront of modern chemical engineering, enabling precise control and synthesis under elevated conditions.

What is a High Pressure Reactor?

Operating on the principle of containing reactions within a controlled environment, high pressure reactors provide a platform for conducting chemical processes at pressures significantly higher than atmospheric levels. These reactors play a pivotal role in various industries, including pharmaceuticals, petrochemicals, and materials science, where reactions necessitate specific pressure conditions for optimal performance.

At the heart of a high pressure reactor vessel lies a robust vessel designed to withstand extreme pressures while maintaining integrity and safety. These vessels are typically constructed from high-quality materials such as stainless steel, titanium, or nickel-based alloys, engineered to endure the rigors of high-pressure environments without compromising performance.

The key advantage of high pressure reactors lies in their ability to facilitate reactions that are otherwise unattainable under standard atmospheric conditions. By subjecting reactants to elevated pressures, these reactors enable enhanced reaction rates, improved selectivity, and the synthesis of novel compounds with unique properties.

Furthermore, high pressure reactors offer precise control over reaction parameters, including temperature, pressure, and residence time, allowing researchers and engineers to optimize reaction conditions and achieve desired outcomes with high reproducibility.

Applications of High Pressure Reactors

High pressure reactor offer numerous advantages in chemical processes due to their ability to control pressure, a critical factor in chemistry.

Under high pressure, solvents can withstand higher temperatures before boiling. This allows reactions to occur at elevated temperatures, leading to quicker reaction rates compared to atmospheric pressure conditions.

Increased pressure directly enhances reaction rates, especially for gas-phase reactions, by decreasing the volume of reactants, thereby increasing concentration and collision frequency.

Furthermore, elevated pressure shifts the chemical equilibrium towards the side of the reaction with fewer gas moles. Depending on the reaction’s stoichiometry, pressure reactors can significantly enhance reaction yield.

Consequently, pressure reactors play a vital role in various chemical applications, including hydrogenations, gas-phase reactions, homogeneous and heterogeneous catalysis, corrosion testing, supercritical studies, and hydrothermal syntheses.

| Type | Applications |

| Chemical Reactants | Solutions, Gases, Solids |

| Catalytic Reactions | Homogeneous and Heterogeneous Catalysis |

| Polymerization and Polymer Synthesis | Polymers, Resins, Plastics |

| Hydrothermal Synthesis | Nanomaterials, Inorganic Crystals, Organic Compounds |

| Supercritical Fluid Extraction | Natural Products, Pharmaceuticals, Chemicals |

| High-Temperature High-Pressure Treatment | Material Sintering, Hydrothermal Treatment, High-Pressure Impregnation |

Considerations:

1. Operators should undergo professional training to understand the operational procedures and safety requirements of high-pressure reactors.

2. Strictly adhere to the operating procedures and safety guidelines outlined in the operation manual when using high-pressure reactors.

3. Continuously monitor and record pressure and temperature during equipment operation to ensure safe operation within specified parameters.

4. Perform regular maintenance and inspections of high-pressure reactors to ensure proper functioning and safety.

5. Take appropriate personal protective measures, such as wearing protective eyewear, gloves, and clothing, when handling chemicals and operating under high-temperature and high-pressure conditions.

6. When dealing with toxic, flammable, or corrosive substances, operate under specially designed fume hoods to ensure indoor air quality and personnel safety.

7. Dispose of residual materials and chemicals properly, and clean and maintain equipment after high-pressure reactor operations.

The versatility of high pressure reactors extends beyond traditional chemical synthesis. They find applications in diverse processes such as hydrothermal synthesis, polymerization, catalysis, and supercritical fluid extraction, among others. Their adaptability to a wide range of reactions and processes underscores their significance in modern industrial and academic research settings.

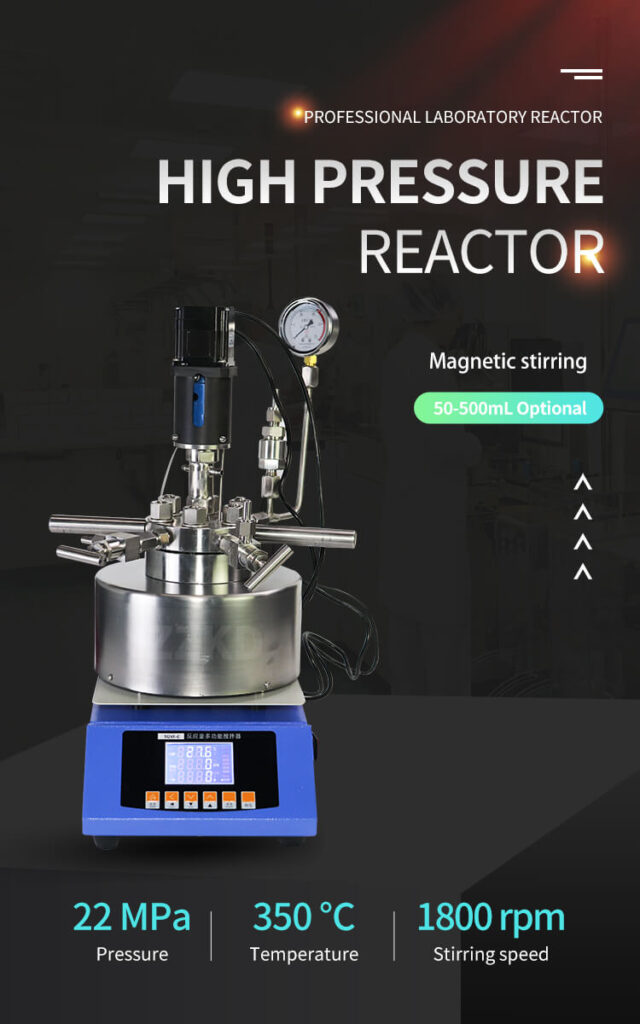

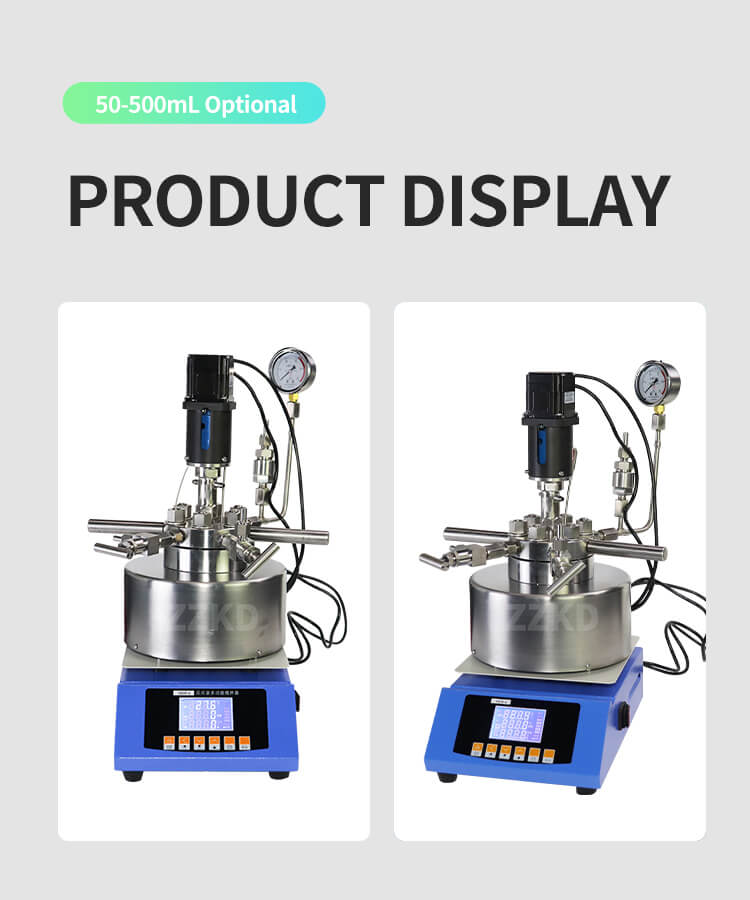

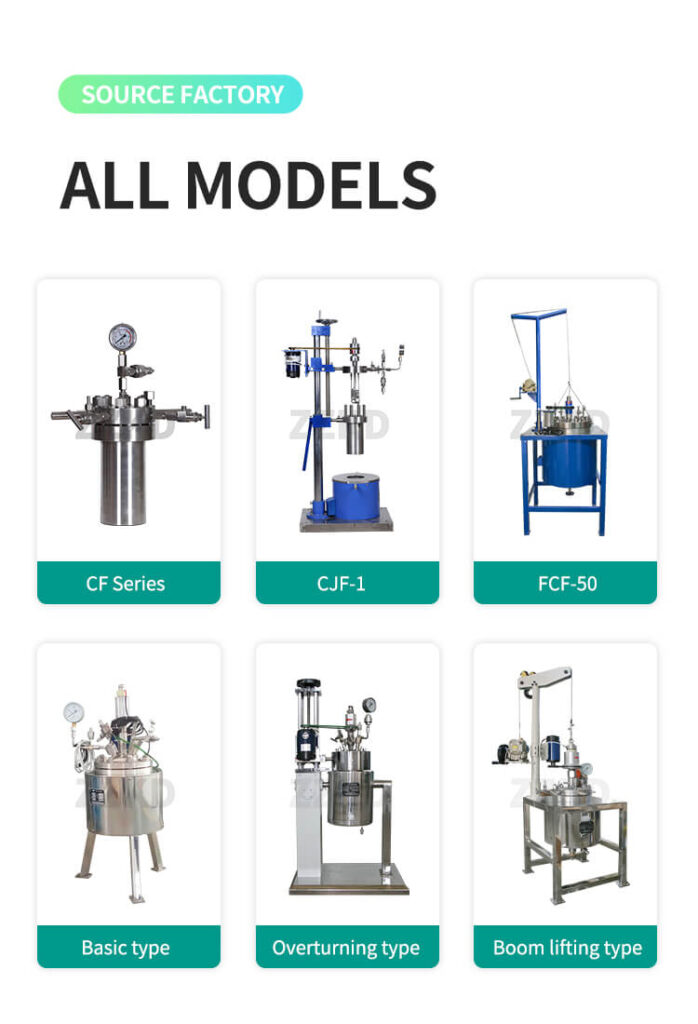

High pressure reactors come in a variety of sizes and specifications tailored to meet a wide range of application needs. For laboratories with limited space, compact benchtop models like the CF-0.1 and CF-0.5 are ideal, accommodating reaction volumes up to 0.5 liters. These reactors feature robust construction using materials like 304L/316L stainless steel and are capable of withstanding pressures of up to 22 MPa.

For larger-scale applications, scale-up high pressure reactors such as the CF-10 and CF-20 are available, designed to handle reaction volumes ranging from 10 to 20 liters. These high-capacity units offer the flexibility to operate at pressures up to 22 MPa, ensuring efficient and reliable performance. Additionally, models like the CF-3 and CF-5 are optimized for mid-range volumes of 3 to 5 liters, with pressure ratings suitable for various experimental conditions.

| Model | Capacity(L) | Pressure(MPa) | Material |

| CF-0.1 | 0.1 | 22 | 304L/316L |

| CF-0.5 | 0.5 | 22 | 304L/316L |

| CF-1 | 1 | 22 | 304L/316L |

| CF-3 | 3 | 10 | 304L/316L |

| CF-5 | 5 | 10 | 304L/316L |

| CF-10 | 10 | 22 | 304L/316L |

| CF-20 | 20 | 22 | 304L/316L |

Integrated with advanced features and materials, high pressure reactors enhance workflow efficiency and accommodate the diverse requirements of modern scientific research and industrial processes. Whether for small-scale experimentation or large-scale production, these reactors provide the precision and reliability necessary for successful outcomes.

In addition to their role in facilitating chemical reactions, high pressure reactors also contribute to the development of sustainable processes and green chemistry initiatives. By enabling the synthesis of complex molecules and functional materials under milder conditions, these reactors promote efficiency, reduce energy consumption, and minimize environmental impact.

High pressure reactors represent indispensable tools in the arsenal of chemical engineers and researchers, empowering the exploration of new frontiers in chemistry and materials science. With their ability to control and manipulate reaction parameters under extreme conditions, these reactors drive innovation and pave the way for the development of advanced materials and technologies with far-reaching implications.