Introduction to Waste Solvent Recovery

In an era where sustainable practices are paramount, the waste solvent recovery system stands as a beacon of environmental stewardship and economic prudence. Integral to this system is the solvent recycler machine, a pioneering technology that transforms waste into reusable solvents. This revolutionary approach not only safeguards our environment by reducing harmful waste but also offers substantial cost savings for industries reliant on solvent use.

Why Solvent Recovery Matters

The importance of solvent recovery stems from its dual benefit of environmental protection and economic gain. Through recycling, companies can significantly cut down the volume of hazardous waste, thereby easing the pressure on waste disposal systems and lessening environmental damage. Economically, it reduces the necessity for new solvent production, which in turn lowers energy consumption and greenhouse gas emissions, embodying a true win-win scenario for businesses and the environment alike.

Understanding the Components of Waste Solvent Recovery

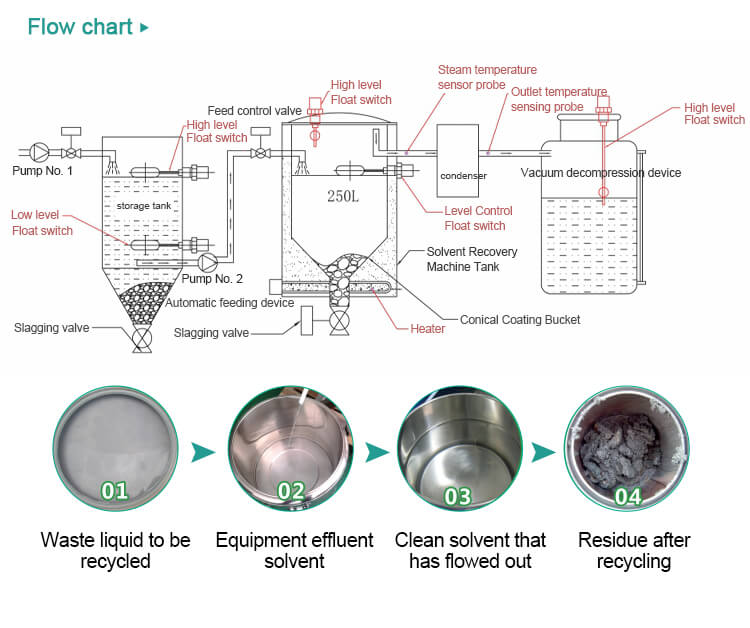

A waste solvent recovery system is a symphony of various components, each playing a vital role in the efficient recovery and repurposing of solvents.

The Distillation Process

Central to the system is the distillation unit, a sophisticated piece of machinery designed to purify solvents. The process involves heating the waste solvent to a vapor state and then condensing it back into a liquid, effectively separating it from impurities. This meticulous process ensures the reclaimed solvent is as good as new, ready for reuse in various industrial applications.

Advanced Filtration Systems

Complementing the distillation process is advanced filtration, a critical step in removing particulate matter and other contaminants. This stage is crucial to maintaining the high quality of the recycled solvent, ensuring it meets industry standards and can be effectively reintegrated into production processes.

The Multifaceted Benefits of Solvent Recovery

The adoption of a waste solvent recovery system offers a myriad of advantages, spanning from environmental benefits to financial savings.

Reducing Environmental Footprint

The most evident benefit is the significant reduction in environmental pollution. By minimizing solvent waste, industries contribute to a healthier ecosystem, aligning with global efforts towards sustainability.

Economic Advantages

Another major incentive for businesses is the reduction in operational costs. The ability to recycle and reuse solvents means a decrease in the need to purchase new solvents, translating into considerable cost savings.

Technological Advancements in Solvent Recovery

The domain of waste solvent recovery is ever-evolving, with new technological advancements continually raising the bar for efficiency and effectiveness.

Automation in Solvent Recovery

Modern recovery systems are increasingly automated, boasting sophisticated control mechanisms that fine-tune the recovery process. This automation ensures optimal solvent yield and quality, reducing the need for manual intervention and streamlining operations.

Focus on Energy Efficiency

Newer systems are also designed with an emphasis on energy efficiency. These energy-efficient models not only reduce the environmental impact but also lower operational costs, making them a smart investment for forward-thinking businesses.

Diverse Industrial Applications

Waste solvent recovery systems have found their place in a wide array of industries, each benefiting from the unique capabilities of these systems.

Pharmaceutical Industry Applications

In the pharmaceutical industry, where solvent purity is of utmost importance, recovery systems are indispensable. They ensure that solvents meet the stringent quality requirements necessary for the production of pharmaceuticals.

Partnering with the Right Manufacturer

For industries looking to embrace solvent recovery, the choice of manufacturer is crucial. ZZKD Machinery and Instrument Equipment Co., Ltd., with its proven track record in producing high-quality distillation and extraction equipment, is an exemplary partner.

To explore how ZZKD can elevate your waste solvent recovery process, visit ZZKD’s website. Discover a range of customized solutions that cater to your industry’s specific needs. Embrace the future of solvent management with ZZKD, and step into a world of sustainable and cost-effective industrial practices.