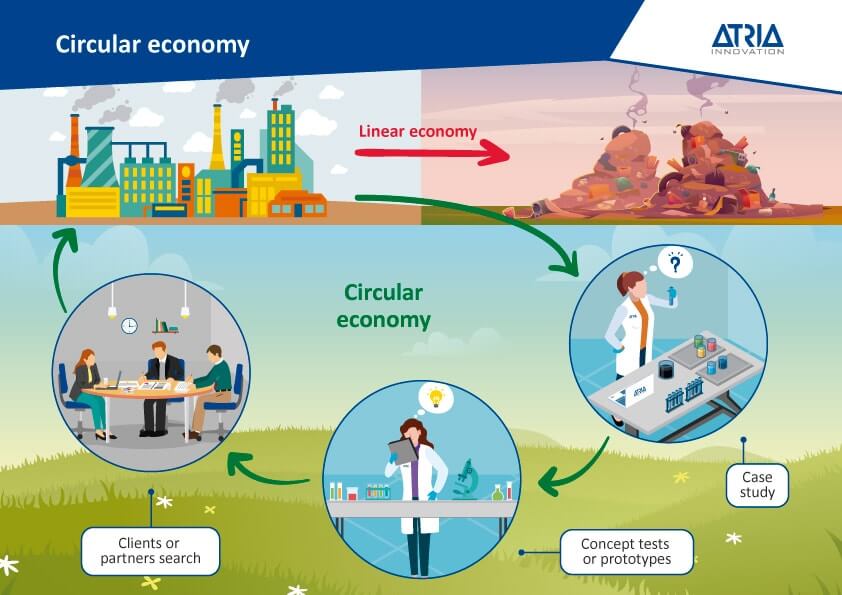

In today’s rapidly evolving world, efficient waste management solutions are crucial for sustainable development. One remarkable innovation in this field is the thinner recycler machine. This cutting-edge technology has the potential to transform the way we recycle and manage waste. By offering a compact and advanced solution, thinner recycler machines enable efficient recycling of thinner materials, reducing environmental impact and promoting a circular economy. In this article, we will explore the features, applications, and benefits of thinner recycler machines and delve into a real-world application case that highlights their effectiveness.

I. Understanding Thinner Recycler Machine

A. Definition and Purpose

Thinner recycler machines are advanced recycling systems designed to process and recycle thinner materials effectively. These machines utilize innovative technologies and processes to break down and transform waste materials into reusable resources, contributing to a more sustainable and circular economy.

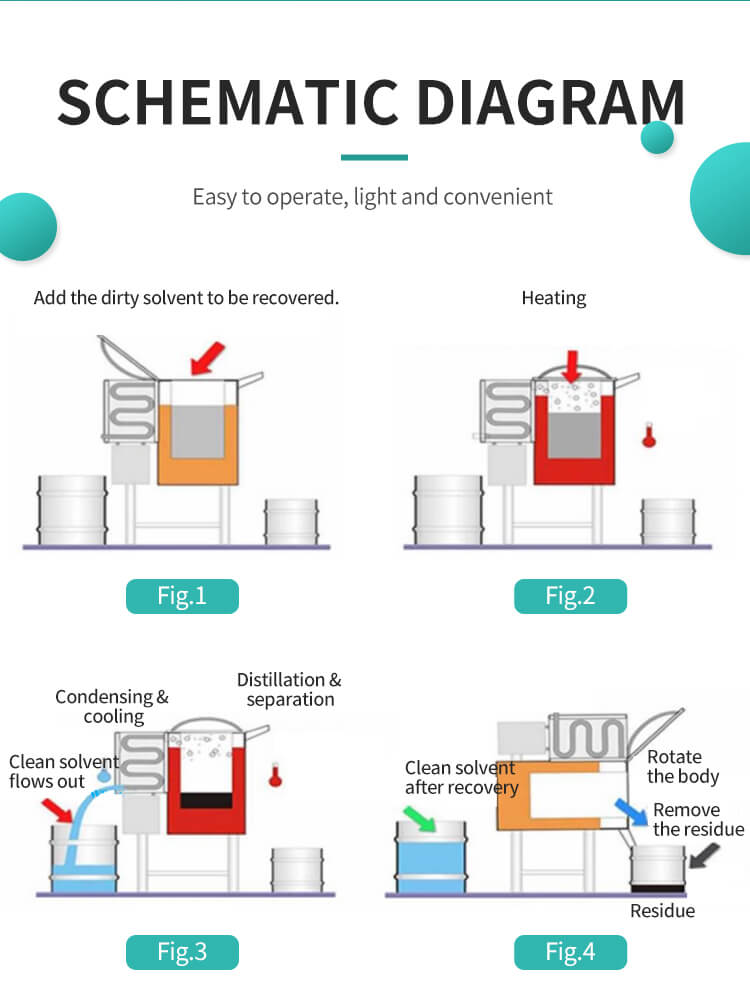

B. Functionality and Operation of Thinner Recycler Machine

Thinner recycler machines employ a combination of mechanical, thermal, and chemical processes to recycle thin waste materials. These machines can handle a wide range of materials, including plastics, metals, paper, textiles, and electronic components.

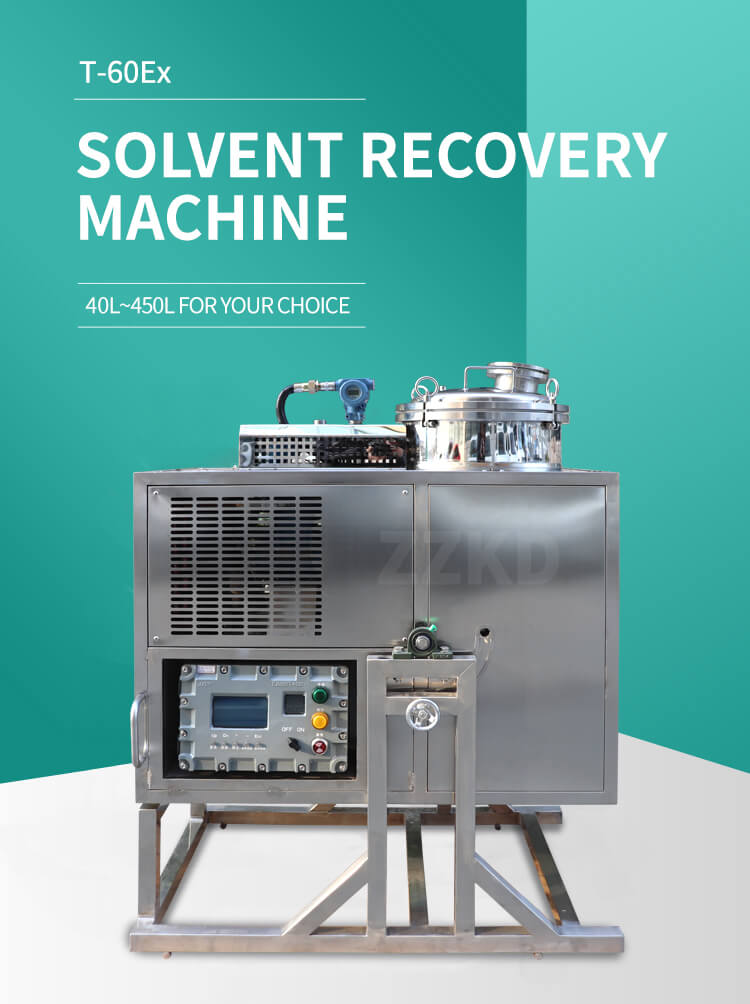

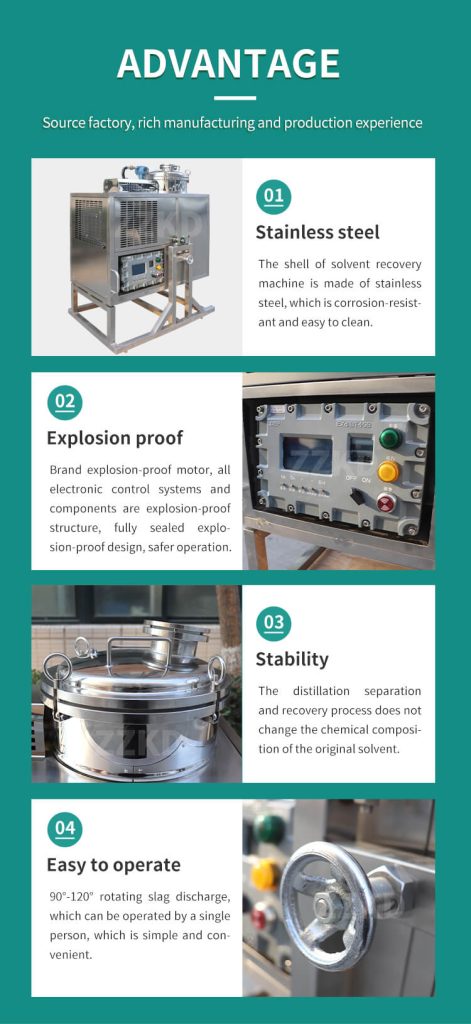

C. Key Components and Design

Thinner recycler machines typically consist of a material feeding system, shredders or cutters, sorting mechanisms, separation units, heating elements, and control panels. The design focuses on efficiency, compactness, and automation, allowing for seamless operation and maximum resource recovery.

II. Applications of Thinner Recycler Machines

A. Industrial Waste Management

Thinner recycler machines play a crucial role in effectively managing industrial waste. Industries generate significant volumes of waste materials, including thin plastic films, packaging materials, and byproducts. By implementing thinner recycler machines in waste management systems, industries can reduce their environmental footprint, minimize landfill waste, and promote sustainable practices.

Thinner recycler machines efficiently process and recycle various waste materials, such as thin plastic films and packaging materials. These machines shred, sort, and transform the materials into reusable resources or raw materials for further manufacturing. By doing so, thinner recycler machines contribute to resource conservation and the promotion of a circular economy.

B. Plastic Recycling and Repurposing

Thinner recycler machines are highly effective in recycling and repurposing thin plastic materials, such as bags, packaging films, and disposable containers. These machines employ advanced technologies to process and convert the materials into reusable plastic pellets or other suitable forms for manufacturing new plastic products.

The process begins with feeding the thin plastic materials into the recycler machine, which shreds them into smaller pieces. Through mechanical and thermal processes, the shredded plastics are transformed into plastic pellets. These pellets can be used as raw materials in various industries, reducing the need for virgin plastics and minimizing environmental impact.

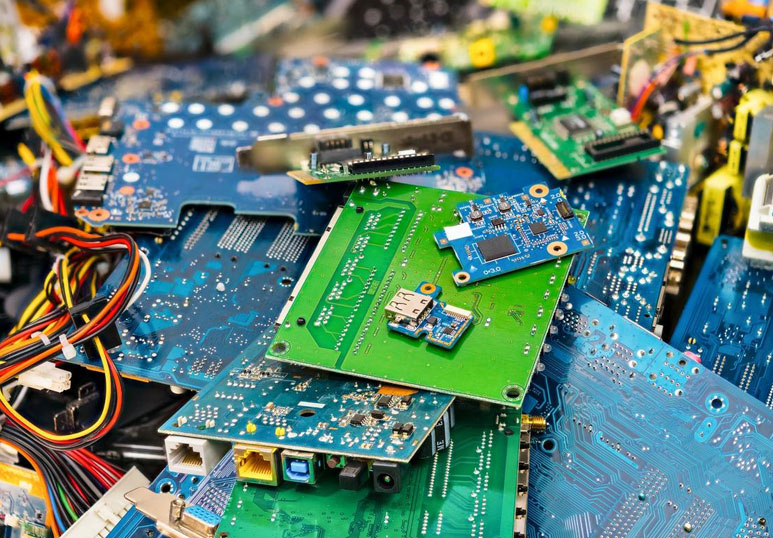

C. Electronic Waste Recycling

Thinner recycler machines play a vital role in recycling thin electronic components, including circuit boards, cables, and connectors. These machines employ advanced sorting mechanisms to extract valuable metals and recover reusable parts from electronic waste. Thinner recycler machines contribute to reducing the volume of e-waste in landfills and conserving precious resources.

By effectively processing thin electronic waste, thinner recycler machines minimize the environmental impact associated with improper disposal. They facilitate the recovery of valuable metals like gold, silver, and copper, which can be reused in manufacturing new electronic devices or sold as raw materials.

III. Advantages and Benefits of Thinner Recycler Machine

A. Environmental Impact and Sustainability

Thinner recycler machines significantly reduce the environmental impact associated with waste disposal. By promoting recycling and resource recovery, they help conserve natural resources, reduce energy consumption, and minimize greenhouse gas emissions. Furthermore, these machines contribute to the diversion of waste from landfills, mitigating the risk of soil and water pollution.

B. Cost-effectiveness and Resource Efficiency

Thinner recycler machines offer cost-effective waste management solutions. By recycling and repurposing waste materials, companies can reduce their reliance on virgin resources and lower production costs. The recovered materials can be used in-house or sold to other industries, providing an additional revenue stream. Moreover, these machines optimize resource utilization by extracting valuable components from waste, extending their lifespan and reducing the need for new raw materials.

C. Reduction of Landfill Waste

One of the primary advantages of thinner recycler machines is their contribution to reducing landfill waste. Thin materials, such as plastic films and packaging materials, often end up in landfills, taking up valuable space and contributing to environmental pollution. Thinner recycler machines enable the efficient processing and recycling of these materials, diverting them from landfills and minimizing waste accumulation.

D. Compliance with Regulations

Thinner recycler machines assist industries and waste management facilities in complying with environmental regulations and standards. These machines enable businesses to meet recycling targets, waste reduction goals, and sustainable practices required by regulatory bodies. By implementing thinner recycler machines, companies can ensure legal compliance while actively contributing to environmental stewardship.

IV. Real-World Application Case

A. Case Study: Thinner Recycler Machines in a Manufacturing Plant

To illustrate the effectiveness of thinner recycler machines, let’s consider a case study in a manufacturing plant. XYZ Manufacturing, a leading producer of consumer goods, implemented thinner recycler machines to manage the large volumes of plastic waste generated during their production processes.

B. Implementation Process and Results

XYZ Manufacturing integrated thinner recycler machines into their waste management system, installing them at strategic points along the production line. The machines were capable of efficiently processing and recycling thin plastic films, scraps, and packaging materials. As a result, XYZ Manufacturing achieved a significant reduction in waste sent to landfills, leading to cost savings and environmental benefits.

C. Testimonials and Feedback

The implementation of thinner recycler machines at XYZ Manufacturing received positive feedback from both employees and stakeholders. Employees appreciated the simplified waste disposal process and the company’s commitment to sustainability. Stakeholders recognized the environmental benefits, improved resource management, and the positive brand image associated with responsible waste management practices.

V. Future Prospects and Innovations

A. Advancements in Technology and Features

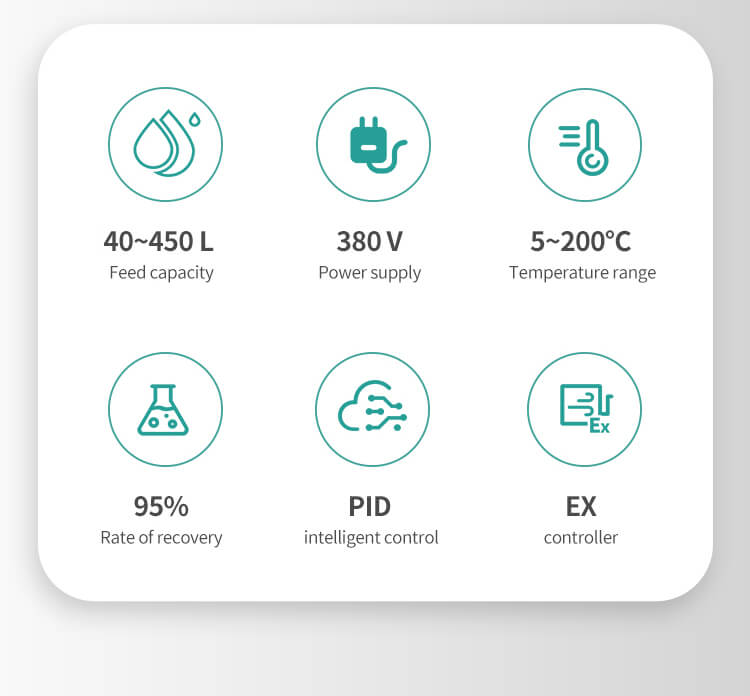

Thinner recycler machines are poised for further advancements in technology. Ongoing research and development efforts focus on improving efficiency, enhancing material compatibility, and reducing energy consumption. Advanced sorting mechanisms, automated control systems, and real-time monitoring capabilities are some of the potential innovations that may be integrated into future iterations of thinner recycler machines.

B. Integration with Smart Systems

The integration of thinner recycler machines with smart systems and Internet of Things (IoT) technologies is another exciting prospect. By connecting these machines to a networked infrastructure, data on waste generation, recycling rates, and machine performance can be collected and analyzed. This data-driven approach would enable better waste management decision-making, predictive maintenance, and optimization of recycling processes.

Thinner recycler machines have emerged as a groundbreaking solution for efficient waste management. Their compact design, advanced functionality, and numerous applications make them a vital tool in promoting sustainability and resource conservation. By enabling the recycling and repurposing of thinner materials, these machines contribute to a circular economy, reduce landfill waste, and minimize the environmental impact associated with waste disposal. As technology continues to advance, thinner recycler machines hold immense potential for further innovation and integration with smart systems, fostering a more sustainable and eco-friendly future. With their wide-ranging benefits and real-world success stories, it is evident that thinner recycler machines are at the forefront of the waste management revolution, propelling us towards a greener tomorrow.