Understanding Glass Batch Reactors

Chemical glass batch reactors are a staple in the laboratory setting, where their clear walls allow for the direct observation of chemical reactions. This transparency is not merely for visual convenience but plays a crucial role in monitoring the progress of reactions, ensuring quality control, and verifying process consistency. In the realm of chemical synthesis, single layer glass reactors facilitate a range of operations from simple mixing to complex, multi-step organic syntheses.

The Essence of Observation

Observation is a key component in chemical experimentation. The ability to see a reaction as it proceeds gives chemists a unique advantage in understanding reaction kinetics and dynamics. This immediate feedback can lead to real-time adjustments, which is essential in maintaining the desired reaction path and ensuring safety in the lab.

Quality Control in Synthesis

Quality control during chemical synthesis is paramount. Glass batch reactors contribute to stringent quality measures by allowing for the detection of impurities, color changes, or phase separations as they occur, which are often indicators of reaction progress or the need for procedural adjustments.

Consistency and Reproducibility

Consistency in chemical production is vital for reproducibility and scale-up processes. Batch reactors made of glass provide a controlled environment where conditions such as temperature and pressure can be precisely managed, leading to consistent batch quality and performance.

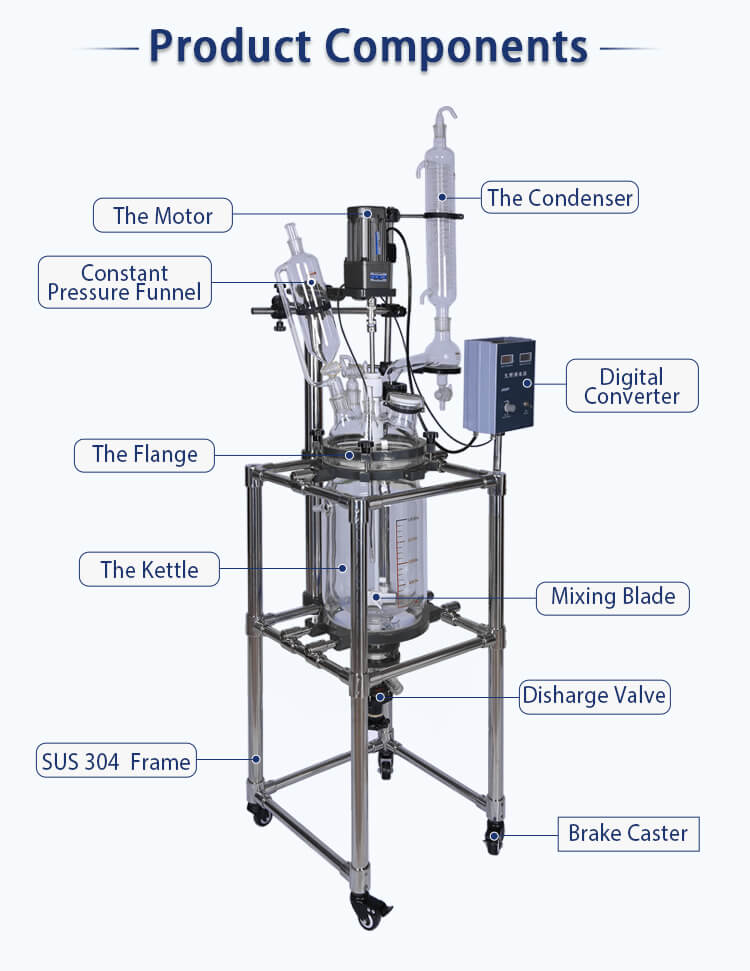

The Design and Construction of Batch Reactors

The design of glass batch reactors is a balance between functionality and durability. The construction must withstand the rigors of chemical reactions while providing the versatility needed for various processes.

Material Considerations

The glass used in these reactors is not ordinary glass. It is often borosilicate, which is resistant to thermal shock and chemical corrosion. This resilience makes it an ideal candidate for the harsh conditions often encountered in chemical synthesis.

Structural Integrity

Despite their seeming delicacy, glass reactors are designed to handle substantial stress. The incorporation of stainless steel in frames and support structures enhances their durability and safety, ensuring they remain a reliable tool in the chemist’s arsenal.

Design Versatility

The modular design of many glass batch reactors allows for customization according to specific needs. This adaptability is crucial when a process requires specialized setups, such as the integration of distillation columns or additional feeding ports.

The Safety Aspects of Glass Reactors

Safety is a non-negotiable aspect of chemical processing, and glass batch reactors are designed with several features to ensure the well-being of laboratory personnel and the integrity of the chemical process.

Chemical Inertness

Glass is inherently resistant to a wide range of chemicals, reducing the risk of unwanted reactions that could compromise safety or product integrity. This inertness also simplifies cleaning procedures, preventing cross-contamination between batches.

Pressure and Temperature Control

Advanced glass reactors are equipped with features to control and withstand variations in pressure and temperature. Safety valves, robust seals, and reinforced viewing ports are standard in these systems, providing peace of mind during exothermic or volatile reactions.

Emergency Handling

In the event of an unexpected reaction, the clear walls of the reactor allow for immediate visual assessment, enabling quick decision-making for emergency interventions. This immediate transparency can be the difference between a controlled response and a hazardous situation.

The Economic and Environmental Considerations

The use of glass batch reactors also touches on economic and environmental concerns, aligning with the principles of green chemistry and cost-efficiency in industrial practices.

Resource Efficiency

The reusability of glass reactors makes them an economically sound choice. Their longevity and ease of maintenance reduce the need for frequent replacements, offering a sustainable option for laboratories and production facilities.

Waste Reduction

By allowing for precise control over reaction conditions, glass batch reactors minimize the production of waste, contributing to more environmentally friendly chemical processes. This efficiency is not only beneficial for the planet but also for the bottom line of companies that use them.

Supporting Green Chemistry

Glass batch reactors are instrumental in advancing the goals of green chemistry. They facilitate the development of cleaner reactions and the use of safer reagents, solvents, and methodologies, which are central to sustainable industrial practices.

Conclusion: The Future of Glass Batch Reactors

The future of glass batch reactors in chemical synthesis is bright. As the demand for more sophisticated and cleaner chemical processes grows, so does the need for equipment that can provide the precision, safety, and flexibility that glass batch reactors offer. Their role in the production of chemicals and pharmaceuticals is not just current but also forward-looking, as they continue to support innovations in chemical research and industrial applications.