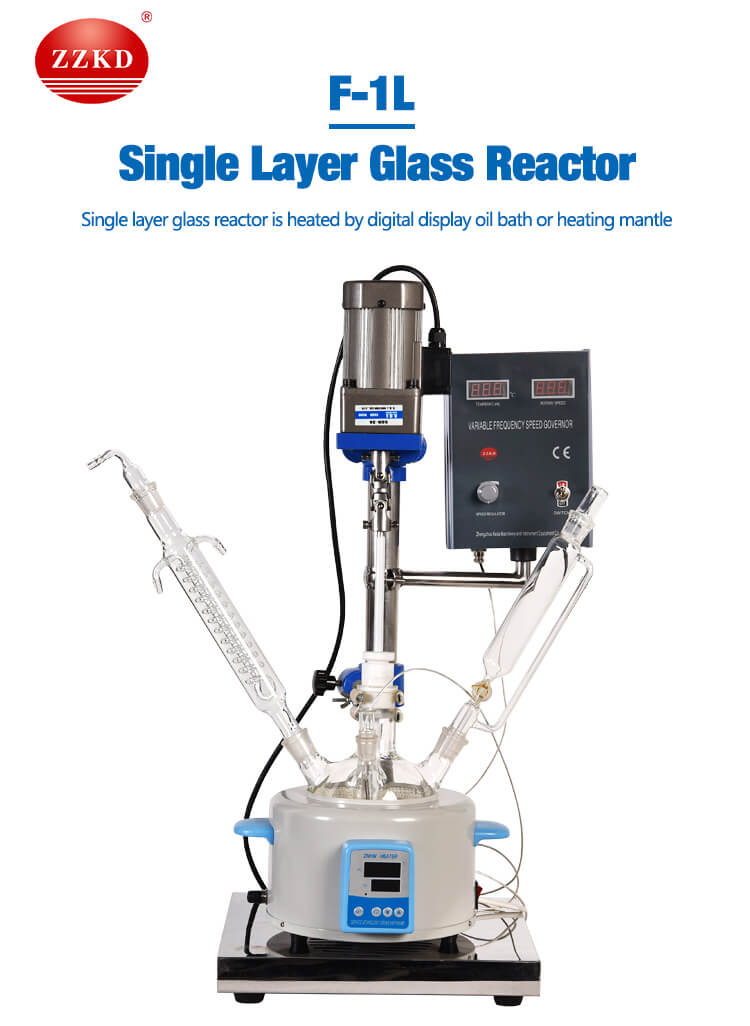

Single layer glass reactor introduction

A single-layer glass reactor is a type of laboratory equipment used for chemical synthesis, distillation, and extraction. It consists of a glass vessel with a single layer, which is usually made of borosilicate glass to withstand high temperatures and chemical reactions.

The single-layer glass reactor can be used for various applications such as mixing, homogenization, and heating of liquids or solutions. It is commonly used in the pharmaceutical, chemical, and biotech industries, as well as in academic research laboratories.

One of the advantages of a single-layer glass reactor is that it is easy to operate and maintain. It is also highly resistant to corrosion and can withstand high temperatures and pressures. Additionally, the glass material is transparent, allowing researchers to observe the chemical reactions taking place inside the vessel.

However, one of the limitations of a single-layer glass reactor is that it has a limited capacity and cannot handle large-scale production. It also cannot withstand highly reactive or corrosive chemicals, and it may not be suitable for reactions that require multi-step processes or complex equipment configurations.

Single layer glass reactor Features:

Material: Single layer glass reactors are typically made of high-quality borosilicate glass material that is resistant to high temperatures, corrosion, and thermal shock.

Capacity: The capacity of a single-layer glass reactor ranges from a few milliliters to several liters, making it suitable for a wide range of applications.

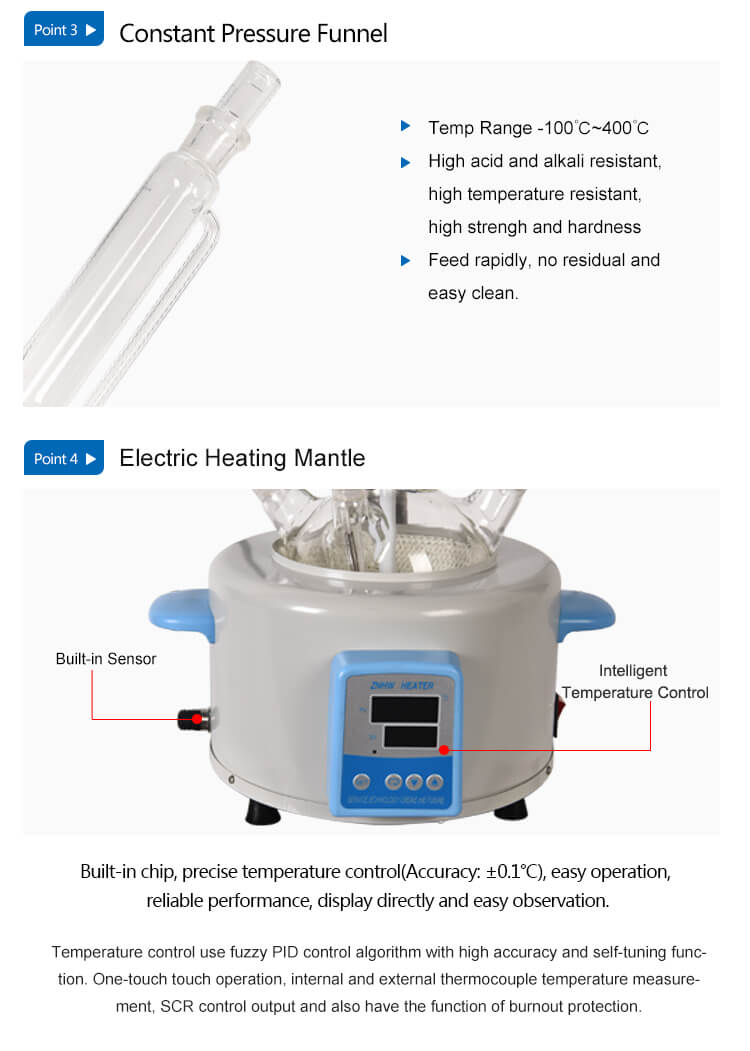

Heating and cooling system: Single-layer glass reactors are equipped with a heating and cooling system that allows researchers to precisely control the temperature inside the reactor.

Stirring system: Single-layer glass reactors usually come with a mechanical or magnetic stirring system that ensures thorough mixing of the reactants.

Pressure rating: Single-layer glass reactors can withstand a range of pressures, depending on their design and capacity.

Easy to clean: The glass material of single-layer glass reactors is easy to clean, making them suitable for multiple applications.

Transparent: The glass material of single-layer glass reactors is transparent, allowing researchers to observe the chemical reactions taking place inside the vessel.

Single layer glass reactor Application:

Single layer glass reactors have a wide range of applications in various fields such as:

Chemical synthesis: Single layer glass reactors are commonly used in the chemical industry for the synthesis of various organic and inorganic compounds.

Distillation: Single layer glass reactors can be used for distillation of liquids and solutions, which is a common process in the chemical industry.

Extraction: Single layer glass reactors can be used for the extraction of compounds from natural sources such as plants and herbs.

Reaction kinetics: Single layer glass reactors are used to study reaction kinetics and to determine reaction rates.

Crystallization: Single layer glass reactors can be used for the crystallization of compounds from solutions.

Mixing and homogenization: Single layer glass reactors can be used for mixing and homogenization of liquids and solutions, which is necessary for many chemical processes.

Biochemical applications: Single layer glass reactors can be used in biochemical applications such as fermentation, cell culture, and protein expression.

The versatility of single layer glass reactors makes them an essential piece of equipment in various fields, including pharmaceuticals, chemicals, biotechnology, and academic research.

Supporting Equipment for single layer glass reactor:

DLSB-5/10 Refrigerated Circulator

Storage Volume: 5L

Low temperature range: -10℃~RT

Refrigeration capacity: 280~620W

Rated Power: 420W

SHZ-D(Ⅲ) Water Circulating Vacuum Pump

Power: 180W

Flow(L/min): 60

Lift(m): 8

Max.Vacuum(Mpa): 0.098

Tank Capacity: 15L

Case : ZZKD Company Selling Single layer glass reactor to a Vietnamese Customer

ZZKD is a leading manufacturer of laboratory equipment, including glass reactors, in China. In March 2023, the company sold a single-layer glass reactor to a Vietnamese customer named Mr. Nguyen.

Mr. Nguyen is a chemistry professor at a prestigious university in Hanoi. He had been searching for a high-quality glass reactor for his laboratory for several months. When he stumbled upon ZZKD’s website, he was impressed with the company’s reputation for producing reliable laboratory equipment. After conducting thorough research, he decided to purchase a single-layer glass reactor from ZZKD.

The purchase process was smooth and efficient. ZZKD’s customer service team was responsive and provided Mr. Nguyen with all the information he needed to make an informed decision. The shipping process was also fast and efficient, with the reactor arriving at Mr. Nguyen’s laboratory in Hanoi in less than a week.

Mr. Nguyen was thrilled with the quality of the single-layer glass reactor. The reactor was easy to set up and operate, and its precision and accuracy surpassed his expectations. He found the reactor to be durable and reliable, making it an excellent investment for his laboratory. Mr. Nguyen was also impressed with the level of customer service he received from ZZKD, stating that the company went above and beyond to ensure his satisfaction.

Overall, Mr. Nguyen was extremely satisfied with his purchase from ZZKD. He would highly recommend the company to anyone in need of high-quality laboratory equipment. ZZKD’s commitment to customer satisfaction and the quality of their products make them a top choice for laboratory professionals worldwide.