In the realm of laboratory equipment, efficiency and sustainability are paramount. One crucial component that contributes to both aspects is the solvent recovery machine. This innovative technology plays a pivotal role in various industries, including pharmaceuticals, chemicals, and research. In this article, we will delve into the significance of thinner recycling machine, their operational mechanisms, benefits, applications, and the role they play in driving sustainable laboratory operations.

Understanding Solvent Recovery Machine

Unveiling the Mechanism

Solvent recovery machines are sophisticated equipment designed to reclaim solvents used in various processes. These machines employ a distillation process, wherein used solvents are heated to their boiling points, causing them to vaporize. The vapors are then condensed back into liquid form, resulting in pure solvent that can be reused. This closed-loop cycle not only reduces solvent wastage but also contributes to significant cost savings.

Operational Efficiency and Cost-effectiveness

Solvent recovery machines are engineered for efficiency. By recovering and reusing solvents that would otherwise be discarded, laboratories can substantially reduce their operational costs. This approach aligns with the principles of sustainable practices, as it minimizes the demand for new solvent production and decreases the overall environmental footprint of laboratories.

Key Benefits and Advantages

Economic Savings: Investing in a solvent recovery machine translates to long-term economic benefits. The initial investment is offset by reduced solvent procurement costs and lower disposal expenses.

Environmental Impact: Solvent recovery machines contribute to a greener environment by curbing solvent waste generation and reducing the need for solvent production, which often involves resource-intensive processes.

Enhanced Productivity: Laboratories can maintain a steady supply of high-quality solvents, eliminating delays caused by waiting for new solvent orders.

Applications of Solvent Recovery Machine

Pharmaceutical Industry

In the pharmaceutical sector, where stringent quality standards and regulatory compliance are paramount, solvent recovery machine play a critical role. These machines enable the reclamation of expensive solvents used in drug synthesis and purification processes, ensuring that valuable resources are not squandered.

Chemical Manufacturing

Chemical manufacturing processes involve the use of various solvents. Solvent recovery machine empower manufacturers to recycle solvents, reducing production costs and minimizing the environmental impact associated with solvent disposal.

Research and Development

Research laboratories rely on a variety of solvents for experimentation and analysis. Solvent recovery machines provide researchers with a continuous supply of solvents, enabling uninterrupted work and contributing to the efficiency of scientific advancements.

Driving Sustainability through Solvent Recovery Machine

Resource Conservation

Solvent recovery machine epitomize resource conservation. By reusing solvents, laboratories contribute to the reduction of raw material consumption, ultimately conserving valuable natural resources.

Waste Reduction

The adoption of solvent recovery machines leads to a significant reduction in solvent waste generation. This reduction aligns with the principles of waste minimization and environmental stewardship.

Carbon Footprint Reduction

The utilization of solvent recovery machines directly impacts carbon emissions. By lowering the demand for solvent production, laboratories can contribute to mitigating their carbon footprint, a crucial step towards combatting climate change.

Selecting the Right Solvent Recovery Machine

Capacity and Scale

When choosing a solvent recovery machine, laboratories must consider their solvent usage volume. Machines come in various capacities, catering to both small-scale laboratories and large industrial facilities.

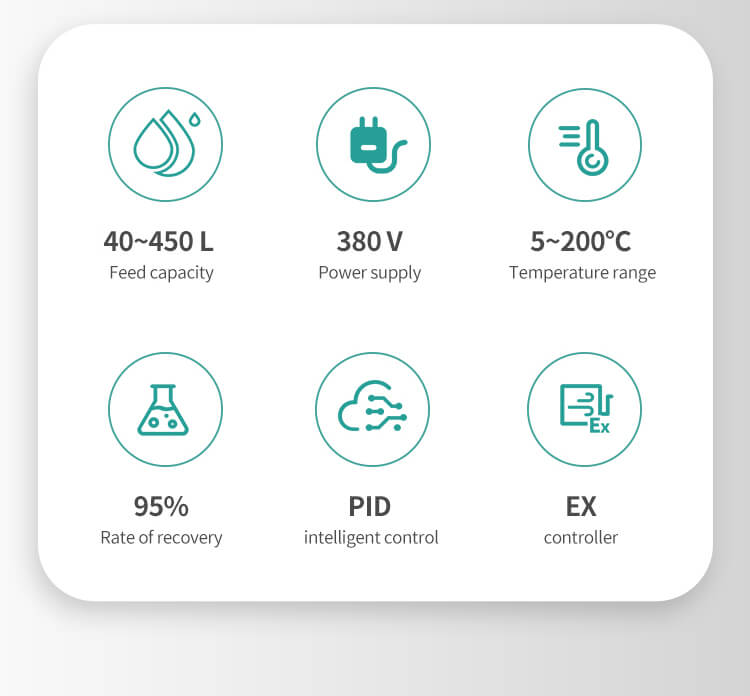

Technological Features

Modern solvent recovery machines are equipped with advanced technological features such as automated controls, real-time monitoring, and safety mechanisms. These features ensure efficient and safe operation.

Compatibility with Solvent Types

Different processes require different types of solvents. It’s essential to select a solvent recovery machine that can handle a diverse range of solvent compositions.

Conclusion

In the dynamic landscape of laboratory operations, solvent recovery machines emerge as champions of efficiency, sustainability, and cost-effectiveness. These innovative devices enable laboratories to reclaim solvents, reduce waste, and minimize their environmental impact. By adopting solvent recovery technology, laboratories can contribute to a more sustainable future while simultaneously enhancing their operational efficiency and economic viability. As laboratories continue to evolve, the role of solvent recovery machines becomes even more significant, bridging the gap between cutting-edge research and responsible resource management.