In today’s environmentally conscious world, finding sustainable solutions is paramount, especially in industries that heavily rely on chemicals and produce hazardous waste. Paint shops, for instance, generate significant amounts of lacquer thinner waste, a common solvent used in the automotive, manufacturing, and woodworking sectors. However, by implementing a lacquer thinner recycler, these businesses can not only reduce their environmental impact but also save costs. This article explores the benefits of a lacquer thinner recycler and its role in promoting sustainability within paint shops.

1. Understanding the Lacquer Thinner Recycler:

A lacquer thinner recycler is an innovative device designed to efficiently and safely remove impurities from used lacquer thinner, allowing it to be reused multiple times. By employing various filtration and distillation processes, this recycler separates contaminants, such as paint particles and residues, from the solvent, restoring it to its original condition. This technology ensures that the recirculated lacquer thinner meets the necessary quality standards for reuse, reducing waste and promoting sustainability in paint shops.

2. Environmental Advantages of a Lacquer Thinner Recycler:

Implementing a lacquer thinner recycler provides several environmental benefits. Firstly, it significantly reduces the amount of hazardous waste generated by paint shops. By recycling and reusing lacquer thinner, the amount of discarded solvent is minimized, leading to fewer harmful substances entering the ecosystem. Secondly, this technology reduces the demand for virgin lacquer thinner production, which often involves the extraction of non-renewable resources and energy-intensive manufacturing processes. By conserving resources, a lacquer thinner recycler helps mitigate the environmental impact associated with the production and disposal of lacquer thinner.

3. Cost Savings and Efficiency:

Apart from the environmental advantages, a lacquer thinner recycler offers substantial cost savings for paint shops. Recycling lacquer thinner eliminates the need to purchase new solvent, resulting in reduced procurement expenses. Additionally, the recycler’s filtration and distillation processes remove impurities, ensuring that the reclaimed solvent maintains its performance qualities, equivalent to or even better than fresh lacquer thinner. Consequently, paint shops can maintain high-quality finishes while minimizing material costs, contributing to improved profitability.

4. Transitioning to a Sustainable Workflow:

Implementing a lacquer thinner recycler in a paint shop requires a shift towards a sustainable workflow. This transition involves proper training and education for the staff to handle the recycler effectively. By providing comprehensive training on the usage, maintenance, and safety procedures associated with the recycler, paint shop operators can optimize its benefits and prevent accidents. Additionally, integrating the recycler into the shop’s waste management protocols ensures a streamlined and sustainable approach to dealing with lacquer thinner waste.

5.Varnish Lacquer Thinner Recycler Recycling Process

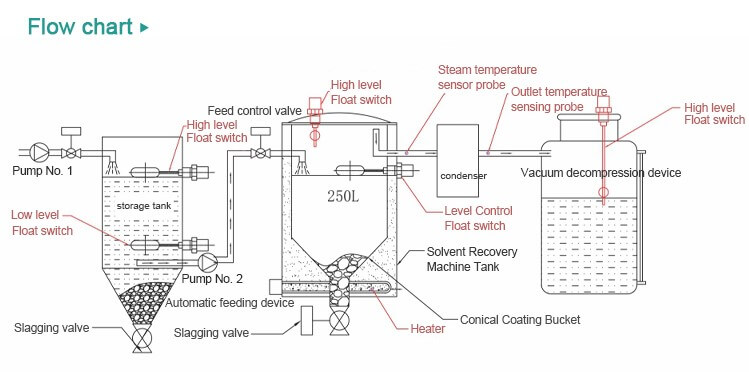

The lacquer thinner recycler offers an efficient and environmentally friendly solution for reusing varnish thinner, reducing waste, and minimizing the impact on the environment. The recycling process involves several steps:

1. Collection: The used varnish thinner is collected in a designated container or tank, typically located near the painting or finishing area. It is important to handle and store the used thinner safely to prevent leaks or spills.

2. Filtration: The collected varnish thinner is first passed through a filtration system. This system helps remove any large particles, debris, or contaminants present in the solvent. Filtration helps improve the quality of the recycled thinner and extends the lifespan of the recycling machine.

3. Distillation: The varnish thinner is then subjected to distillation. In this process, the solvent is heated to a high temperature, causing it to vaporize. The resulting vapor is collected and cooled, condensing it back into a purified liquid form. Distillation separates the varnish thinner from impurities, such as paint residues or other substances, ensuring that the recycled thinner meets quality standards.

4. Solvent Recovery: The condensed, purified varnish thinner is further processed to recover as much solvent as possible. Techniques like condensation or cooling are used to collect the condensed solvent.

5. Disposal of Residues: During the recycling process, solid residues or impurities may accumulate. These residues, need to be properly managed and disposed of according to local regulations.

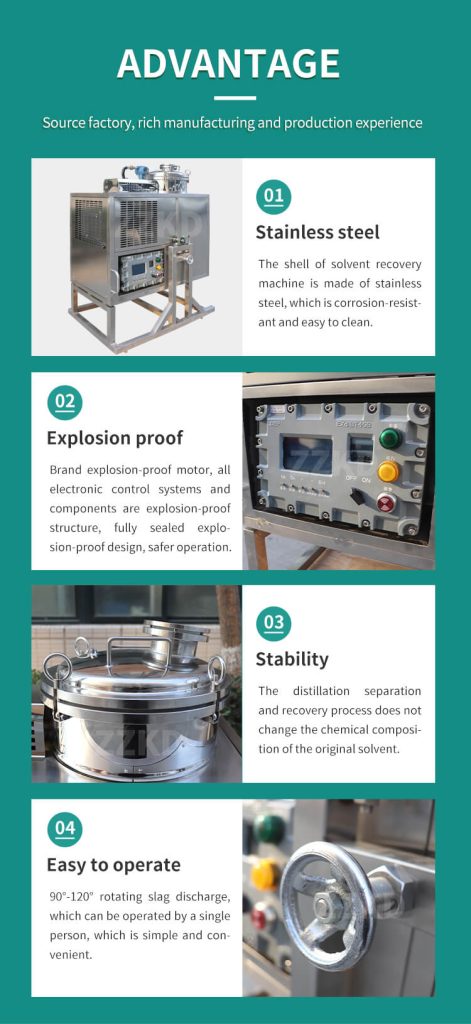

6. Safety Measures: Varnish thinner recycling machines often incorporate safety features to prevent accidents and promote user protection. These may include temperature and pressure monitoring systems, automatic shut-off mechanisms, and ventilation systems to control fumes and prevent the buildup of volatile vapors.

By reusing the solvent, businesses and individuals can contribute to a more sustainable approach in painting and finishing applications.

6. Regulatory Compliance and Safety:

Properly managing lacquer thinner waste is not only essential for environmental sustainability but also crucial for compliance with regulatory standards. Improper disposal of hazardous waste can lead to legal repercussions and potential harm to human health and the environment. A lacquer thinner recycler helps paint shops meet these regulations by effectively treating the waste on-site. This eliminates the need for costly third-party waste disposal services and reduces the risk of accidents during transportation. By prioritizing safety and regulatory compliance, paint shops can protect their workers, community, and reputation.

The implementation of a lacquer thinner recycler in paint shops offers numerous advantages, ranging from environmental sustainability to cost savings and regulatory compliance. This innovative technology enables paint shops to reduce their environmental footprint by minimizing hazardous waste generation and conserving resources. Additionally, the recycler’s ability to reclaim and maintain the quality of lacquer thinner ensures high-performance finishes while reducing material costs. By embracing this sustainable solution, paint shops can contribute to a greener future while enhancing their operational efficiency and profitability.