In the ever-evolving world of chemical synthesis and material science, the high pressure reactor system stands out as a pivotal innovation. Among these systems, the high pressure autoclave reactor is particularly noteworthy for its robustness and versatility, offering researchers and industrialists a tool to explore reactions under unique conditions that were once deemed challenging or impossible.

Understanding High Pressure Reactor Systems

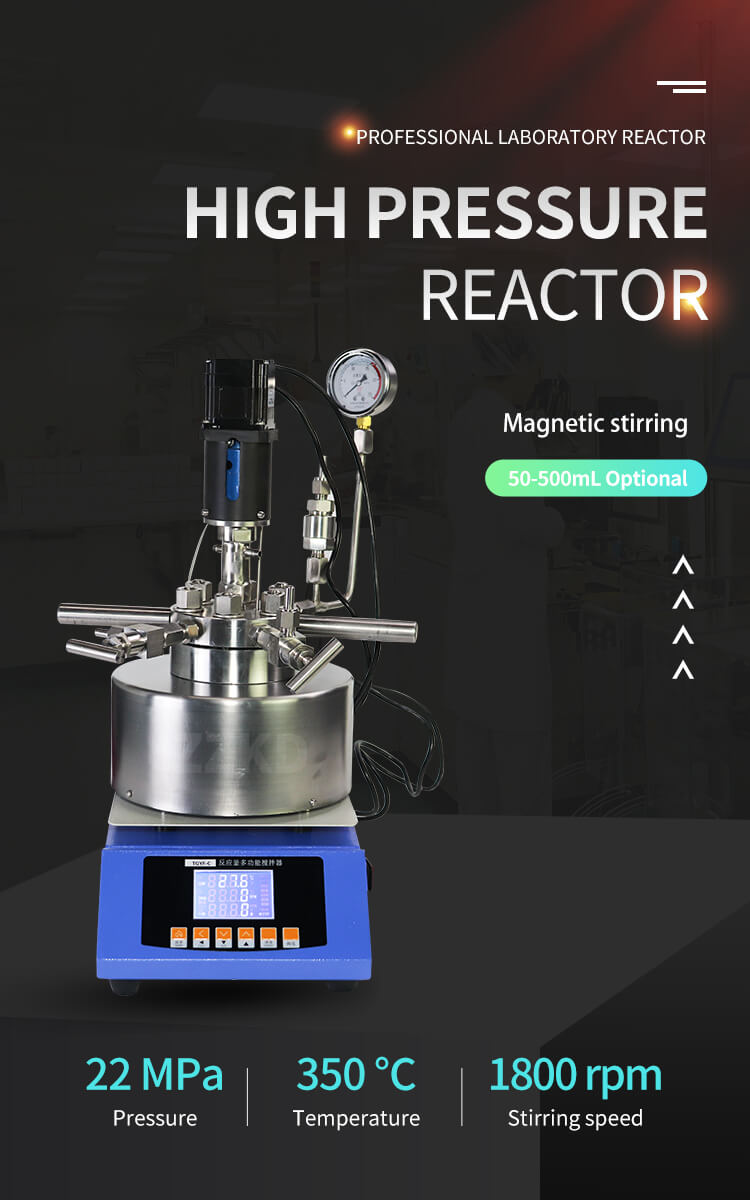

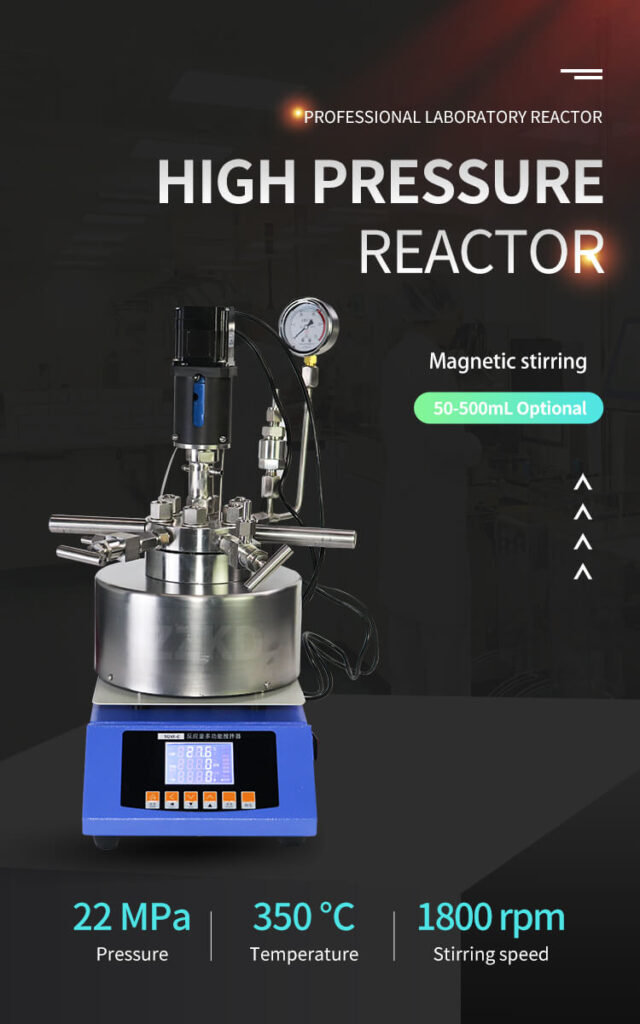

At its core, a high pressure reactor system is designed to handle reactions under significantly elevated pressures. This capability is crucial in manipulating reaction parameters, such as temperature and pressure, to achieve desired outcomes that are unattainable under normal conditions. The system typically comprises a sealed vessel made of materials like stainless steel or special alloys, capable of withstanding extreme conditions.

The Role of Pressure in Chemical Reactions

Pressure plays a critical role in chemical reactions. By increasing pressure, the high pressure reactor system can significantly alter the rate and equilibrium of a reaction. This alteration can lead to the formation of new compounds, increased reaction rates, and the possibility of conducting reactions that are otherwise not feasible at atmospheric pressure.

High Pressure Autoclave Reactor: A Closer Look

The high pressure autoclave reactor, a subtype of the high pressure reactor system, is particularly known for its strong, sealed environment. It can maintain consistent pressure and temperature over extended periods, making it ideal for reactions that require precise and stable conditions. This reactor type is commonly used in polymerization, hydrothermal synthesis, and other processes requiring stringent control.

Applications in Industry and Research

The applications of high pressure reactor systems are vast and varied. In the pharmaceutical industry, they are used to synthesize new drug compounds. In material science, they aid in the development of novel materials with unique properties. The system’s ability to mimic deep-sea conditions also makes it invaluable in studying ocean chemistry and biology.

Advancements in High Pressure Reactor Technology

Recent advancements in high pressure reactor technology have led to more efficient, safer, and user-friendly systems. Innovations include better pressure control mechanisms, enhanced safety features, and the integration of computer-aided monitoring and control systems. These improvements have expanded the system’s applications and accessibility.

Environmental Impact and Sustainability

The high pressure reactor system also plays a significant role in environmental sustainability. It enables the development of greener chemical processes by reducing waste and energy consumption. Additionally, it aids in the synthesis of biofuels and supports research in carbon capture and storage technologies.

Challenges and Future Directions

Despite its numerous advantages, the high pressure reactor system faces challenges, particularly in scaling up for industrial applications. Addressing issues related to safety, cost, and efficiency is crucial for its broader adoption. Future research is likely to focus on developing more robust materials for reactor construction and enhancing system automation.

Conclusion

The high pressure reactor system, especially the high pressure autoclave reactor, is a cornerstone technology in modern chemical synthesis and material science. Its ability to manipulate reaction conditions opens up new possibilities in various fields, from drug development to environmental science. As technology advances, we can expect these systems to become even more integral to scientific and industrial processes, driving innovation and sustainability.