High pressure laboratory reactor have become indispensable tools in various scientific and industrial fields, contributing significantly to research and experimentation. In this blog news article, we delve into the world of high pressure autoclave reactor, their diverse applications, and how they are shaping modern industries.

Evolution of High Pressure Laboratory Reactor

High pressure laboratory reactors have come a long way in terms of design, capabilities, and applications. Over the years, they have evolved from simple vessels to sophisticated systems with precise control mechanisms. These reactors are designed to operate at elevated pressures and temperatures, making them suitable for a wide range of applications. Whether it’s in chemistry, materials science, or chemical engineering, high pressure laboratory reactor play a pivotal role in driving innovation.

In the early days, high pressure laboratory reactors were primarily used for chemical synthesis, particularly in the development of new compounds and materials. As research expanded, their utility grew to encompass various industries, including pharmaceuticals, petrochemicals, and nanotechnology. Today, these reactors are essential tools for scientists and engineers seeking to explore the boundaries of high-pressure reactions and achieve breakthroughs in their respective fields.

The evolution of high pressure laboratory reactor is closely tied to advancements in materials science and manufacturing techniques. These reactors are now built with precision-engineered components that can withstand extreme conditions, ensuring safety and reliability in high-pressure experiments. Furthermore, modern high pressure laboratory reactors offer enhanced control over parameters like temperature, pressure, and stirring speed, enabling researchers to fine-tune their experiments with unprecedented accuracy.

Applications Across Diverse Industries

High pressure laboratory reactor find applications in a wide array of industries, each benefiting from their unique capabilities:

1. Pharmaceutical Research

In the pharmaceutical industry, high pressure reactors are invaluable for developing new drug formulations and chemical processes. They facilitate the synthesis of novel compounds and enable researchers to study the effects of high pressure on drug stability and reactivity.

Pharmaceutical scientists use high pressure reactors to optimize drug formulations, ensuring the safety and efficacy of new medications. This level of precision in research aids in bringing life-saving drugs to market more efficiently.

2. Petrochemical Engineering

Petrochemical processes often involve high-pressure reactions. High pressure laboratory reactors are crucial for the development and optimization of processes in this industry. They are used to study catalysts, explore new chemical pathways, and improve the efficiency of petrochemical operations.

Researchers in this field rely on high pressure laboratory reactor to simulate the conditions found in refineries and petrochemical plants. This allows them to identify potential issues, optimize processes, and reduce environmental impacts.

3. Materials Science

High pressure reactors have revolutionized materials science by enabling the creation of new materials with unique properties. These reactors are used to synthesize advanced materials, such as high-performance polymers, ceramics, and superconductors.

Materials scientists leverage high pressure laboratory reactor to explore the behavior of materials under extreme conditions. This knowledge paves the way for innovations in industries like aerospace, electronics, and renewable energy.

Innovations in High Pressure Laboratory Reactor

In recent years, high pressure laboratory reactor have witnessed remarkable innovations that enhance their usability and reliability. These innovations are driven by the demand for more precise control, safety, and versatility in high-pressure experiments.

1. Enhanced Safety Features

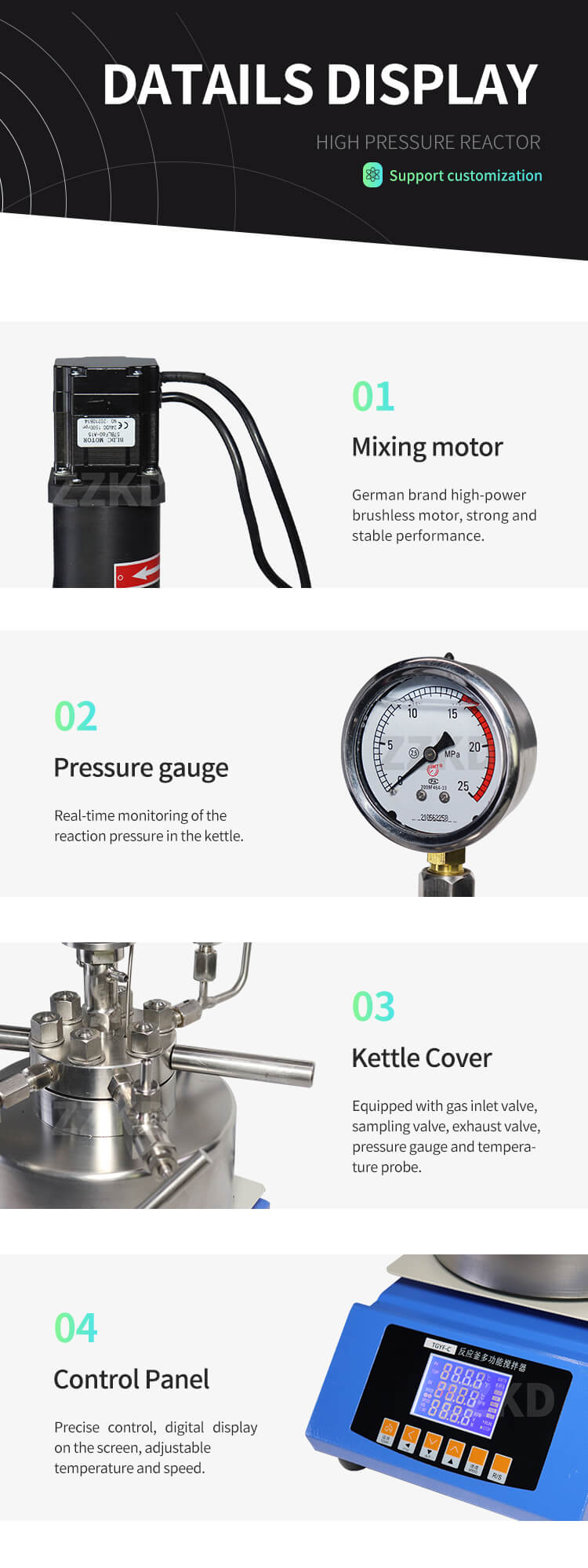

Safety is a paramount concern in high pressure experiments. Innovations in reactor design have led to the integration of multiple safety features. These include advanced pressure relief systems, emergency shutdown mechanisms, and remote monitoring capabilities. Such improvements ensure that researchers can work with high pressure reactors confidently, knowing that risks are minimized.

2. Digital Control Systems

The integration of digital control systems has transformed the way researchers operate high pressure laboratory reactor. These systems allow for precise and real-time control over parameters like pressure, temperature, and stirring speed. Researchers can now create highly controlled environments for their experiments, leading to more accurate and reproducible results.

3. Modular Design

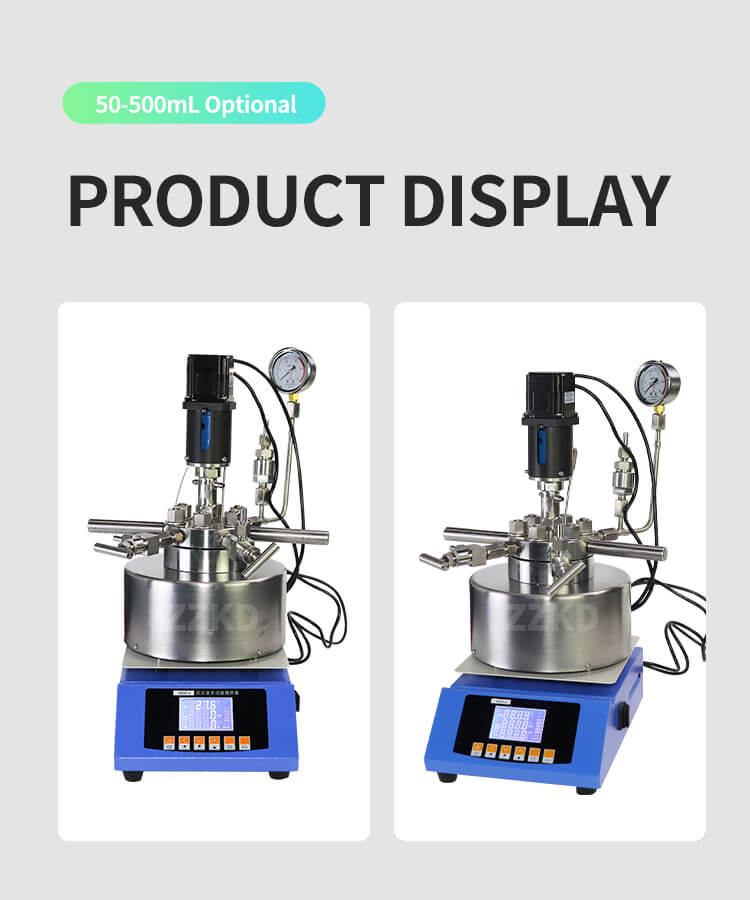

Modern high pressure laboratory reactor often feature a modular design. This allows researchers to customize the reactor setup according to their specific experimental needs. Whether it’s changing vessel sizes, adding additional probes, or incorporating different types of agitators, the flexibility offered by modular reactors streamlines the research process.

Future Prospects for High Pressure Laboratory Reactor

The future of high pressure laboratory reactor looks promising. As industries continue to push the boundaries of what’s achievable under high-pressure conditions, these reactors will play a vital role in making new discoveries and advancements possible. With ongoing research and development efforts, we can expect even safer, more precise, and versatile high pressure laboratory reactor in the years to come.

In conclusion, high pressure laboratory reactors are instrumental in advancing research and innovation across various fields. Their evolution, diverse applications, and recent innovations underscore their critical role in shaping the future of scientific and industrial progress. Researchers and engineers can look forward to an exciting future filled with new possibilities, thanks to these remarkable instruments.