Benchtop rotary evaporator have revolutionized the field of laboratory research, offering scientists a versatile and efficient tool for separating and purifying liquids. This article aims to provide a comprehensive understanding of benchtop rotary evaporators, exploring their functionality, applications, and advantages. By delving into the key features and considerations, researchers and scientists can make informed decisions about incorporating this essential equipment into their laboratories.

I. Understanding Benchtop Rotary Evaporator

A. Definition and Working Principle of Benchtop Rotary Evaporator

A benchtop rotary evaporator is a laboratory device used to remove solvents from liquid mixtures through evaporation. Its compact design and user-friendly interface make it suitable for small-scale applications. This equipment employs a rotating flask, a water or oil bath, a condenser, and a vacuum pump to facilitate the process of evaporation.

B. Key Components and Features

1. Rotating Flask: The heart of the benchtop rotary evaporator, the rotating flask, holds the liquid mixture to be evaporated and ensures efficient heat transfer.

2. Water or Oil Bath: The bath provides a uniform and controlled temperature to the rotating flask, enabling rapid evaporation.

3. Condenser: The condenser cools and condenses the vaporized solvents, converting them back into liquid form for collection.

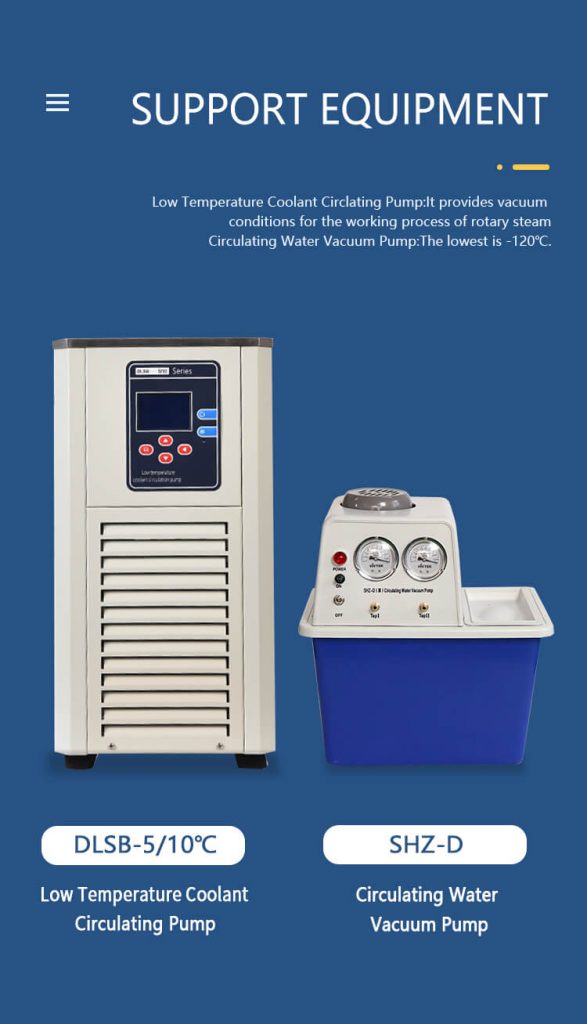

4. Vacuum Pump: The vacuum pump lowers the pressure inside the system, reducing the boiling point of the solvents and accelerating the evaporation process.

5. Controls and Safety Features: Benchtop rotary evaporators come equipped with user-friendly controls and safety features to ensure precise operation and prevent accidents.

II. Applications of Benchtop Rotary Evaporator

A. Chemical Synthesis and Drug Discovery

Benchtop rotary evaporators play a crucial role in chemical synthesis and drug discovery processes. They enable efficient solvent removal and compound purification. These versatile tools find applications in pharmaceutical research, aiding drug development and small molecule synthesis. In drug discovery, benchtop rotary evaporators facilitate the isolation and purification of target compounds. With precise temperature and pressure control, these evaporators extract essential oils from plants for various industries. Their versatility makes them indispensable for environmental analysis, identifying volatile organic compounds in air, water, and soil samples. Benchtop rotary evaporators are valuable assets in advancing scientific endeavors.

B. Essential Oil Extraction

Essential oil extraction benefits from benchtop rotary evaporators, which ensure controlled temperature and pressure for optimal separation. These versatile tools are instrumental in obtaining high-quality, concentrated extracts. With precise temperature and pressure control, benchtop rotary evaporators facilitate the separation of essential oils from plant material. These extracted oils find applications in aromatherapy, cosmetics, and food and beverage industries. Their compact design and user-friendly interface make them ideal for small-scale essential oil extraction. Benchtop rotary evaporators enable researchers to achieve efficient and reliable results in their extraction processes, contributing to various industries’ product development and innovation.

C. Environmental Analysis

Benchtop rotary evaporators are vital in environmental analysis, aiding in the detection and quantification of volatile organic compounds (VOCs). These devices expedite the evaporation and collection of target compounds. Researchers employ benchtop rotary evaporators to analyze air, water, and soil samples for pollutants. The precise separation and identification of VOCs assist in environmental monitoring and remediation efforts. These versatile tools provide researchers with efficient and reliable methods for analyzing and quantifying pollutants, contributing to a better understanding of environmental impacts and ensuring the preservation of ecosystems and human health.

III. Advantages of Benchtop Rotary Evaporator

A. Space Efficiency and Portability

Unlike their larger counterparts, benchtop rotary evaporators have a compact design, making them ideal for laboratories with limited space. Their portability allows researchers to easily move and reconfigure the equipment based on their specific needs.

B. User-Friendly Operation

Benchtop rotary evaporators are designed with user convenience in mind. They feature intuitive controls, allowing scientists to set and adjust parameters such as temperature, rotation speed, and vacuum level. This ease of operation saves time and enhances productivity in the lab.

C. Enhanced Safety Features

Modern benchtop rotary evaporators incorporate advanced safety features to protect users and prevent accidents. These may include automatic shutdown mechanisms, overheating alarms, and safety interlocks that ensure proper sealing and pressure control.

IV. Key Considerations when Choosing a Benchtop Rotary Evaporator

A. Evaporating Capacity and Speed

The evaporating capacity and speed of a benchtop rotary evaporator are critical factors to consider. The flask size, motor power, and heating capacity should align with the sample volume and desired evaporation rate, enabling efficient and timely separation of solvents.

B. Temperature Control and Precision

Precise temperature control is essential for optimal evaporating conditions. Look for a benchtop rotary evaporator that offers accurate and adjustable temperature control, ensuring reproducibility and consistency in your experiments.

C. Vacuum Pump Selection

The choice of vacuum pump significantly impacts the performance of a benchtop rotary evaporator. Consider factors such as ultimate vacuum level, pumping speed, and chemical compatibility to meet the requirements of your specific applications.

D.Ease of Use and Maintenance

Check for user-friendly controls, intuitive interface, and ease of maintenance. Look for features like digital displays, programmable settings, and easy access to components for cleaning and maintenance.

E.Safety Features

Consider safety features like automatic shut-off, overheat protection, and adjustable safety limits to protect the system and samples from potential risks.

F.Reputation and Support

Research the manufacturer’s reputation, customer reviews, and available technical support. Choose a reliable brand with good customer service to ensure a smooth experience and prompt assistance if needed.

V. Transitioning to Efficient Evaporation: Tips and Best Practices

A. Optimize Process Parameters

By carefully adjusting process parameters such as temperature, vacuum level, and rotation speed, researchers can enhance the efficiency of the evaporation process. Conducting preliminary trials and optimizing these parameters can lead to significant time and solvent savings.

B. Regular Maintenance and Cleaning

To ensure reliable performance and extend the lifespan of your benchtop rotary evaporator, it is essential to conduct regular maintenance and cleaning. Follow the manufacturer’s guidelines for cleaning the glassware, changing vacuum pump oil, and inspecting seals and connections.

Benchtop rotary evaporators are indispensable tools in modern laboratory research, offering a range of benefits, including space efficiency, user-friendly operation, and enhanced safety features. Their applications in chemical synthesis, essential oil extraction, and environmental analysis make them versatile and valuable equipment for scientists across various fields. By considering the key features and best practices outlined in this article, researchers can make informed decisions when selecting a benchtop rotary evaporator that aligns with their specific requirements, ultimately enhancing their scientific endeavors.