“Rotovap chemistry” refers to the science and technique behind the use of rotary evaporators (often called rotovaps) in chemical laboratories. A rotary evaporator is a device used to gently and efficiently remove solvents from samples through the process of evaporation under reduced pressure.

This method is widely applied in organic chemistry, pharmaceuticals, and food technology. By lowering the pressure inside the system, the boiling point of the solvent decreases, allowing for faster and safer solvent removal without damaging temperature-sensitive compounds.

Why is vacuum pressure important in a rotary evaporator?

Vacuum pressure plays a crucial role because it allows solvents to evaporate at much lower temperatures. This minimizes the risk of thermal degradation and speeds up the process. According to a study by the University of Cambridge, reducing pressure can lower solvent boiling points by up to 70%, leading to significant energy savings in laboratory operations.

How Does a Rotary Evaporator Work?

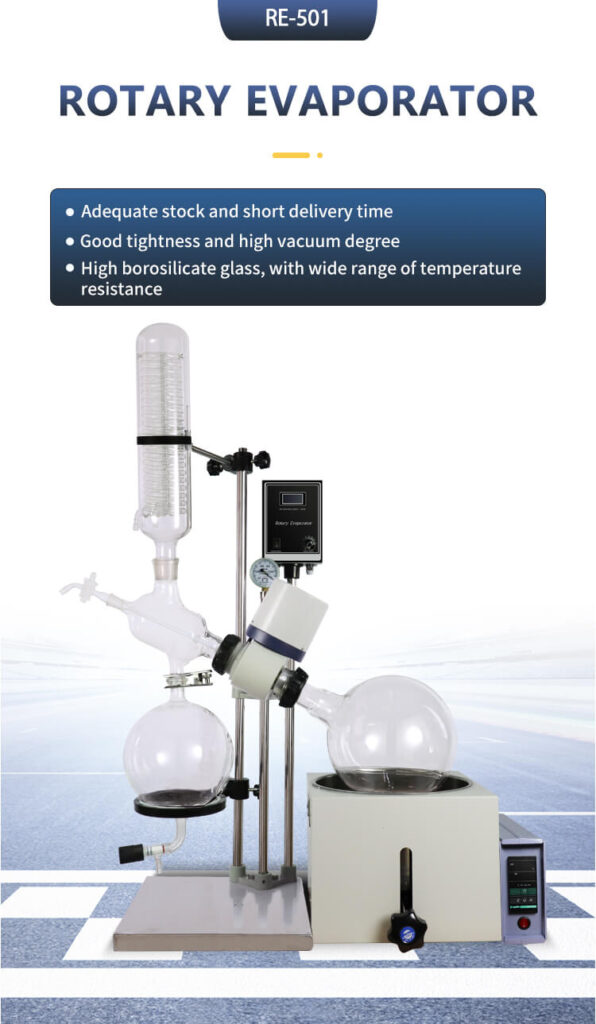

The rotary evaporator consists of several main components: a rotating flask, a water or oil bath, a condenser, and a collection flask. The sample solution is placed in the rotating flask, which spins continuously to increase the surface area for evaporation. The gentle rotation also prevents bumping and ensures even heating.

The solvent vapor travels through the condenser, where it cools down and condenses back into liquid form, collecting in the receiving flask. The entire process takes place under vacuum, making it efficient and safe for delicate compounds.

Applications of Rotovap Chemistry

Rotary evaporators are indispensable tools across multiple industries:

- Organic Chemistry: Used for solvent removal after reactions and for concentrating samples.

- Pharmaceutical Research: Essential for purification of active ingredients and solvent recovery.

- Food and Beverage: Applied in flavor extraction, concentration of natural essences, and alcohol removal.

- Environmental Science: Used for analyzing pollutants and concentrating environmental samples.

According to data from the American Chemical Society (ACS), over 85% of chemical laboratories worldwide use rotary evaporators as part of their solvent recovery systems.

Can rotary evaporators be used for large-scale industrial processes?

Yes. While rotovaps are traditionally associated with laboratory-scale operations, industrial versions are available for large-volume solvent recovery and purification. For example, solvent distillation units integrate similar principles but on a much larger scale, offering high efficiency and automation.

Choosing the Right Rotovap for Your Laboratory

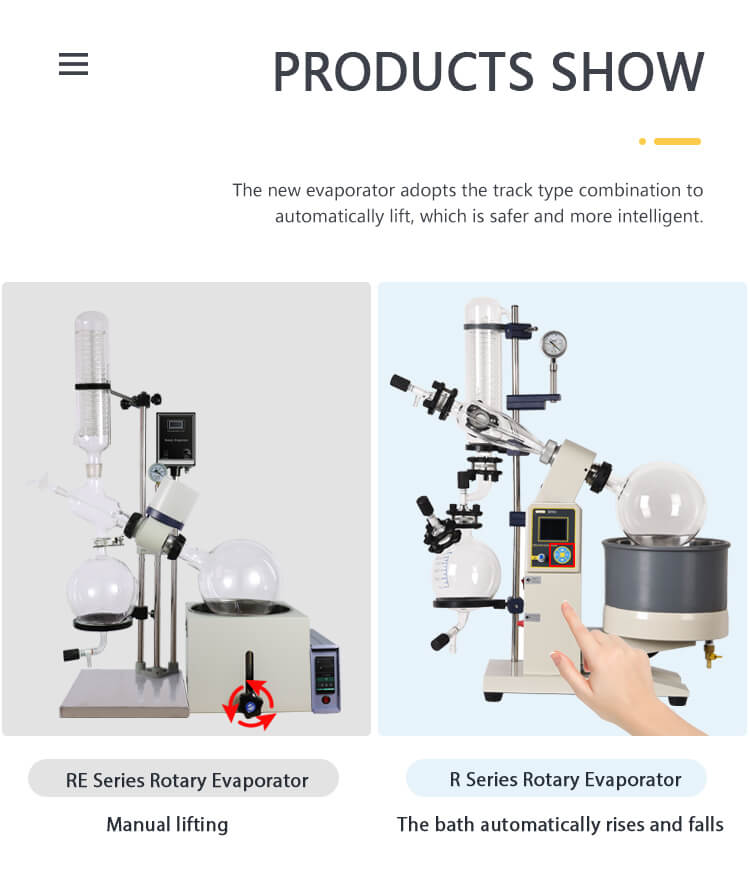

When selecting a rotary evaporator, consider factors such as flask capacity, vacuum control precision, temperature range, and condenser efficiency. For small-scale research or educational labs, compact models are ideal. Industrial users might prefer larger systems with automated vacuum and temperature control.

You can explore advanced designs and pricing details at rotovap price to compare different models and specifications.

Safety and Best Practices

Safety is paramount when working with solvents and vacuum systems. Always ensure that glassware is free from cracks, and never exceed recommended rotation speeds or bath temperatures. Proper ventilation and use of compatible solvents are essential to prevent accidents.

According to the National Institute for Occupational Safety and Health (NIOSH), improper solvent handling accounts for 12% of laboratory accidents annually. Implementing proper training and using modern, automated rotovap systems can reduce this risk significantly.

How can solvent recovery be optimized in rotovap chemistry?

Optimization involves controlling vacuum pressure, bath temperature, and rotation speed. Using efficient condensers and high-quality vacuum pumps improves recovery rates. For industrial applications, systems like solvent recycling machines can further enhance efficiency by automating solvent separation and purification.

Future Trends in Rotovap Chemistry

The future of rotovap chemistry lies in automation and sustainability. Modern rotary evaporators are being integrated with digital controls, AI-based monitoring, and energy-efficient designs. According to a 2023 report by the European Chemical Engineering Society, automation in lab equipment could increase process efficiency by up to 40% by 2030.

Additionally, the push toward green chemistry encourages solvent recycling and reduced waste. This aligns perfectly with the capabilities of rotary evaporators, making them central to sustainable laboratory practices.

Conclusion

Rotovap chemistry is more than just a laboratory technique—it’s a cornerstone of modern chemical research and production. Whether in academia, pharmaceuticals, or food science, rotary evaporators provide a safe, efficient, and sustainable solution for solvent removal and recovery.

For those looking to upgrade laboratory efficiency or implement solvent recovery systems, exploring advanced models like high pressure autoclave reactors or solvent recovery units can provide a comprehensive solution for integrated chemical processes.