Spray dried milk powder is a stable, easily transportable form of milk produced by rapidly drying liquid milk using hot air in a spray dryer. This process removes moisture while preserving nutrients, flavor, and solubility. According to a 2022 report from the International Dairy Federation, global milk powder production exceeded 6 million metric tons, with spray drying accounting for more than 70% of industrial output.

How Does Spray Drying Work?

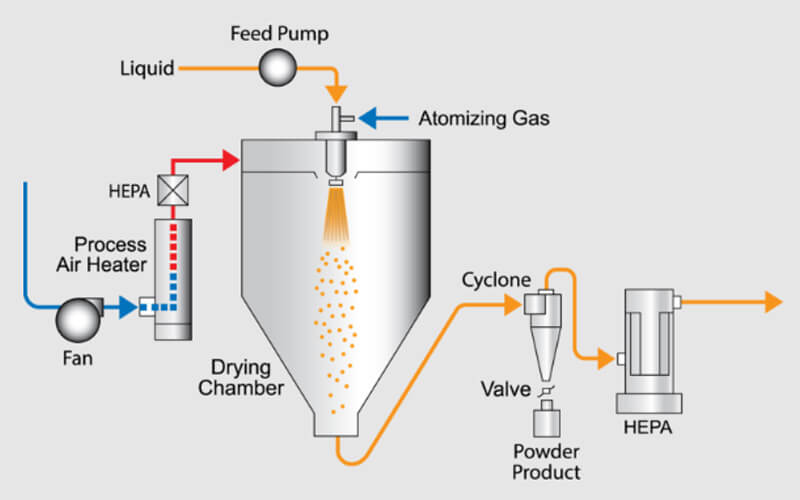

Spray drying involves atomizing liquid milk into fine droplets and exposing them to a stream of hot air inside a drying chamber. The moisture evaporates almost instantly, leaving fine milk powder particles that are collected at the bottom.

Did you know? The spray drying process can reduce milk moisture content to less than 4%, making it safe for long-term storage without refrigeration.

Key Steps in Spray Drying

- Pre-heating milk to improve drying efficiency

- Atomizing milk into micro-droplets

- Rapid moisture evaporation using hot air

- Powder separation and packaging

Why is spray drying preferred over freeze drying for milk powder production?

Spray drying is faster, more energy-efficient, and suitable for large-scale continuous production. Freeze drying, while excellent for preserving sensitive compounds, is slower and more expensive, making it less practical for bulk milk powder manufacturing.

Benefits of Spray Dried Milk Powder

Spray dried milk powder offers several advantages:

- Extended shelf life without refrigeration

- Easy transport and storage

- Consistent quality and solubility

- Versatility in food and beverage applications

Can spray dried milk powder retain the same nutritional value as fresh milk?

Yes. If processed correctly, spray dried milk powder retains proteins, carbohydrates, fats, and most vitamins found in fresh milk. However, certain heat-sensitive vitamins may slightly degrade during drying.

Industrial Applications

Spray dried milk powder is used in bakery products, confectionery, infant formula, and instant beverages. The technology is also applied in pharmaceuticals and nutraceuticals for producing powdered supplements.

Related Equipment

What is the typical moisture content in commercial spray dried milk powder?

Commercial spray dried milk powder usually contains less than 4% moisture, ensuring stability and preventing microbial growth.

Authoritative Data

According to a 2021 study by the Food and Agriculture Organization (FAO), the demand for milk powder is projected to grow by 2.1% annually until 2030, driven by the increasing popularity of convenience foods and global trade in dairy products.

Comparison Table: Spray Drying vs Freeze Drying

| Feature | Spray Drying | Freeze Drying |

|---|---|---|

| Processing Speed | Fast (seconds) | Slow (hours) |

| Energy Efficiency | High | Low |

| Scale | Industrial continuous | Small batch |

| Cost | Lower | Higher |