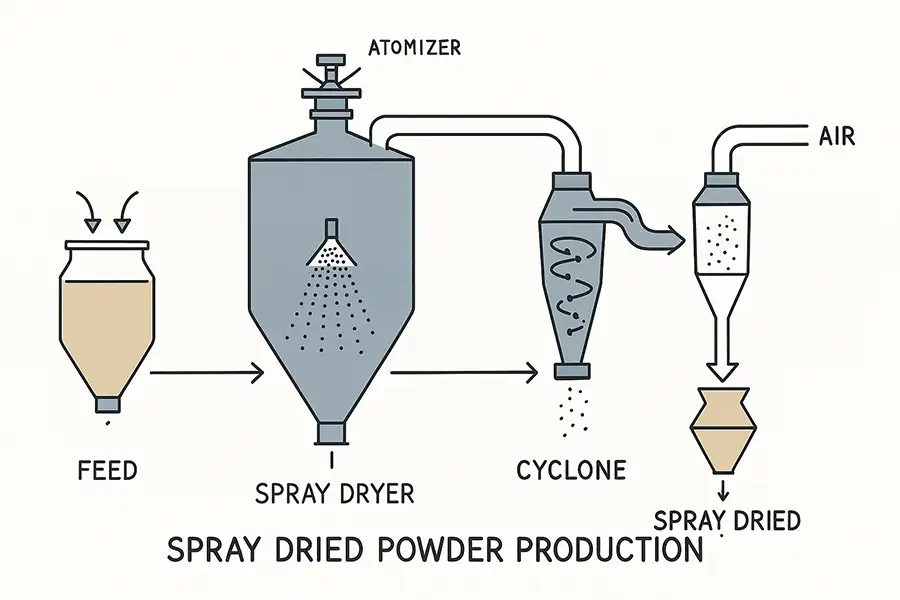

Spray drying atomization is a widely used industrial process that transforms liquid feed into dry powder form by rapidly drying with hot gas. This technique is essential in the food, pharmaceutical, chemical, and materials industries, offering precise control over particle size, moisture content, and product stability.

What is Spray Drying Atomization?

In simple terms, spray drying atomization involves breaking a liquid solution or suspension into fine droplets, exposing them to a stream of hot air, and collecting the resulting dry particles. The atomization step is crucial because it determines the droplet size, which directly affects drying efficiency and final product quality.

Why is atomization so critical in spray drying?

Atomization controls droplet size distribution, which influences drying speed, heat transfer, and the physical properties of the final powder. Smaller droplets dry faster and more uniformly, reducing the risk of overheating or incomplete drying.

How Atomization Works

Atomization can be achieved using various devices such as rotary atomizers, pressure nozzles, or ultrasonic atomizers. Each method has distinct advantages:

- Rotary Atomizers: Ideal for large-scale production, producing uniform droplets.

- Pressure Nozzles: Suitable for smaller scale or lab applications; flexible in droplet size control.

- Ultrasonic Atomizers: Used for sensitive materials requiring low shear forces.

Applications Across Industries

Spray drying atomization is used in:

- Food industry: Instant coffee, milk powder, flavorings.

- Pharmaceuticals: Antibiotics, probiotics, and heat-sensitive drugs.

- Chemicals: Detergents, catalysts, pigments.

- Advanced materials: Ceramic powders, battery materials.

According to a report by Grand View Research (2023), the global spray drying equipment market size was valued at USD 4.5 billion and is expected to grow at a CAGR of 6.8% from 2024 to 2030, driven by demand for high-quality powders in food and pharma sectors.

Benefits of Spray Drying Atomization

Key advantages include:

- Consistent particle size and shape.

- Extended shelf life of products.

- Scalability from laboratory to industrial production.

- Ability to process heat-sensitive materials.

Can spray drying atomization handle heat-sensitive materials?

Yes. By controlling inlet and outlet temperatures, as well as droplet size, spray drying can process materials like probiotics or enzymes without significant loss of activity.

Choosing the Right Equipment

When selecting a spray dryer, factors to consider include capacity, droplet size range, temperature control, and cleaning requirements. For laboratory research, a mini spray dryer or benchtop spray dryer offers flexibility and precision. For industrial use, larger rotary atomizer systems are preferred.

Recent Innovations

Modern spray dryers incorporate AI-based process monitoring, enabling real-time adjustments to airflow, temperature, and atomization speed. According to a study by the University of Cambridge (2022), AI-driven control systems can reduce energy consumption in spray drying by up to 20% while maintaining product quality.

How does AI improve spray drying atomization efficiency?

AI analyzes sensor data to optimize parameters, ensuring consistent droplet formation and drying rates, which reduces waste and energy costs.

Conclusion

Spray drying atomization is a versatile and efficient method for producing high-quality powders. Whether in food, pharmaceuticals, or advanced materials, understanding and optimizing the atomization process is key to achieving desired product characteristics. With innovations like AI integration and improved nozzle designs, spray drying continues to evolve, offering even greater control and efficiency for manufacturers worldwide.

Explore more about spray drying and related technologies at: