In the realm of chemical processing, precision and reliability are paramount. As industries strive for greater efficiency and sustainability, the demand for cutting-edge equipment has never been higher. Enter the high pressure stainless steel chemical reactor – a game-changing apparatus that embodies the pinnacle of engineering excellence.

Born out of the need for robust and versatile equipment capable of withstanding extreme conditions, high pressure stainless steel reactors emerged as a solution to the complex challenges encountered in chemical synthesis, polymerization, and material science. Through continuous refinement and innovation, they have evolved into indispensable tools that underpin modern industrial processes.

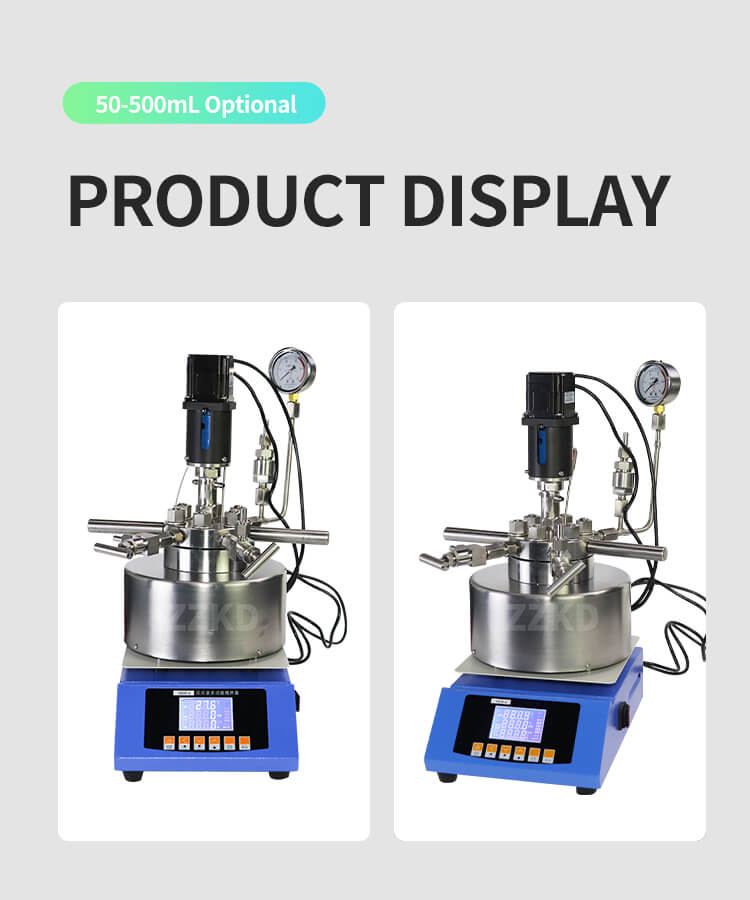

Components of High Pressure Stainless Steel Reactor

At the core of every high pressure stainless steel reactor lies a symphony of meticulously engineered components, each playing a pivotal role in ensuring optimal performance and safety. Let us delve into the anatomy of these marvels of engineering:

1. Stainless Steel Vessel: The cornerstone of the reactor, the stainless steel vessel serves as the chamber for chemical reactions under high pressure. Constructed from premium-grade stainless steel alloys renowned for their corrosion resistance and durability, these vessels provide a robust and inert environment conducive to a wide range of applications.

2. High Pressure Seals and Gaskets: To contain the intense pressures generated within the reactor, high pressure seals and gaskets are employed at critical junctures. Engineered to withstand extreme conditions, these components ensure a hermetic seal, preventing leakage and safeguarding personnel and equipment.

3. Pressure Control System: Essential for maintaining precise control over operating conditions, the pressure control system regulates the internal pressure of the reactor with unparalleled accuracy. Equipped with advanced sensors, valves, and actuators, this system enables operators to fine-tune parameters according to specific requirements, optimizing performance and ensuring reproducibility.

4. Heating and Cooling Mechanisms: Temperature control is paramount in chemical processing, particularly in exothermic reactions where heat dissipation is critical. High pressure stainless steel reactors are equipped with advanced heating and cooling mechanisms, such as jacketed vessels and internal coils, allowing for precise regulation of reaction temperature and rapid thermal management.

Applications of High Pressure Stainless Steel Reactor

The versatility of high pressure stainless steel reactors extends across a myriad of industries and applications, empowering researchers and manufacturers to push the boundaries of innovation. Let us explore some key areas where these reactors have catalyzed transformative advancements:

1. Chemical Synthesis: High pressure stainless steel reactors facilitate the synthesis of novel compounds and materials through precise control over reaction conditions. From pharmaceuticals to specialty chemicals, these reactors enable researchers to explore new avenues of synthesis with unparalleled efficiency and reproducibility.

2. Polymerization: In the realm of polymer science, high pressure stainless steel reactors play a pivotal role in the production of high-performance polymers with tailored properties. By subjecting monomers to elevated pressures and temperatures, researchers can achieve controlled polymerization processes, yielding polymers with precise molecular weights and structures.

3. Material Science: The quest for advanced materials with exceptional properties drives research in fields such as nanotechnology, catalysis, and renewable energy. High pressure stainless steel reactors serve as indispensable tools for synthesizing and characterizing novel materials, enabling breakthroughs in areas such as carbon nanotubes, metal-organic frameworks, and hydrogen storage materials.

4. Hydrothermal Processing: Hydrothermal reactions, which occur under high pressure and temperature in aqueous environments, hold immense promise for various applications, including biomass conversion, waste valorization, and mineral processing. High pressure stainless steel reactors provide the ideal platform for conducting hydrothermal experiments, facilitating the exploration of sustainable and eco-friendly processes.

Advantages of High Pressure Stainless Steel Reactor

The adoption of high pressure stainless steel reactors confers a multitude of advantages, making them indispensable assets for laboratories and manufacturing facilities alike. Let us examine some of the key benefits:

1. Corrosion Resistance: Stainless steel alloys are renowned for their exceptional corrosion resistance, ensuring the longevity and integrity of high pressure reactors even when subjected to aggressive chemical environments.

2. Versatility: High pressure stainless steel reactors are highly versatile, accommodating a diverse range of reactions and processes across various industries. From catalyst testing to material synthesis, these reactors excel in diverse applications, offering unmatched flexibility and adaptability.

3. Safety: With robust construction and stringent quality standards, high pressure stainless steel reactors prioritize safety in high-pressure operations. Advanced safety features, such as pressure relief valves and redundant pressure monitoring systems, mitigate risks and safeguard personnel and equipment.

4. Scalability: Whether in a laboratory setting or industrial production facility, high pressure stainless steel reactors offer scalable solutions tailored to the specific needs of each application. From bench-scale experiments to large-scale manufacturing, these reactors provide seamless scalability, ensuring consistent performance at every stage of development.

High pressure stainless steel reactors represent the epitome of innovation and reliability in chemical processing. Their unparalleled capabilities and versatility empower researchers and manufacturers to explore new frontiers, unlock novel materials, and advance scientific knowledge. As we stand on the precipice of a new era of discovery and progress, the role of high pressure stainless steel reactors in shaping the future of chemical processing cannot be overstated. With each reaction conducted, each material synthesized, and each innovation realized, these reactors pave the way for a brighter, more sustainable future.