In today’s rapidly evolving industrial landscape, sustainability isn’t just a buzzword; it’s a necessity. As companies strive to minimize their environmental footprint and adhere to stricter regulations, finding efficient ways to recycle waste materials has become paramount. One such material that poses significant challenges in recycling is solvent. However, with the advent of advanced paint solvent recycling machine for sale, businesses can now revolutionize their approach to waste management while saving costs and reducing their environmental impact.

Understanding the Challenge

Have you ever considered the environmental impact of the solvents used in your industrial processes? Are you aware of the volume of waste solvent generated by your operations and the associated costs of disposal? The reality is that solvent waste poses significant challenges for businesses across various industries. From manufacturing and pharmaceuticals to automotive and printing, the improper disposal of solvents can lead to environmental pollution, health hazards, and regulatory non-compliance.

The Solution: Solvent Recycling Machines

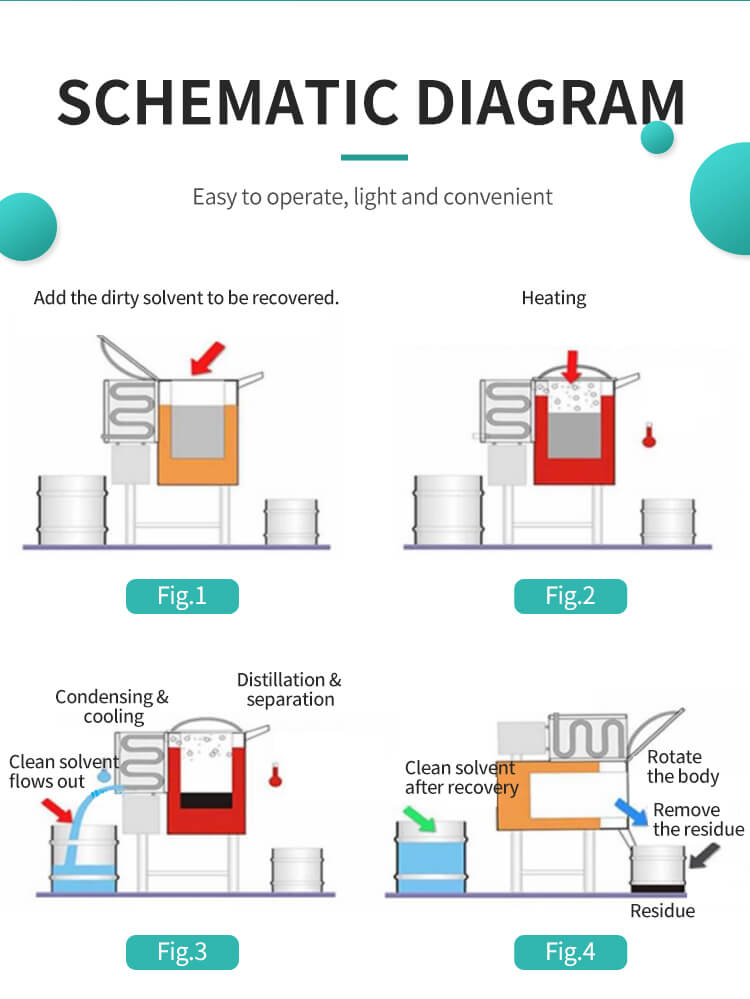

But what if there was a solution that not only addressed these challenges but also offered tangible benefits for your business? Enter solvent recycling machines. Have you explored the potential of solvent recycling technology to transform your waste management practices? These innovative devices are specifically designed to reclaim used solvents, removing impurities and contaminants to produce high-quality recycled solvent that can be reused in industrial processes. But how exactly do solvent recycling machines work, and what benefits can they offer for your business?

Unlocking the Benefits

Are you looking for ways to reduce operating costs and improve your bottom line? Are you committed to minimizing your environmental impact and enhancing your corporate social responsibility? The benefits of implementing a solvent recycling program using solvent recycling machines are manifold. By recycling waste solvents instead of purchasing new ones, businesses can achieve significant cost savings while promoting environmental sustainability. But that’s not all—solvent recycling also offers:

Environmental Protection: Are you concerned about the environmental impact of your industrial activities? By recycling solvents, businesses can minimize hazardous waste generation and reduce their overall environmental footprint. This, in turn, helps protect ecosystems, wildlife, and human health.

Regulatory Compliance: Are you aware of the regulatory requirements governing the handling and disposal of hazardous waste, including solvents? Implementing a solvent recycling program ensures compliance with these regulations, reducing the risk of fines, penalties, and legal liabilities.

Resource Conservation: Are you looking for ways to conserve natural resources and promote a circular economy? By reusing solvents through recycling, businesses can minimize the demand for virgin materials and reduce their reliance on finite resources.

Enhanced Reputation: Are you interested in enhancing your brand image and attracting environmentally conscious customers and partners? Demonstrating a commitment to environmental stewardship through solvent recycling can enhance your reputation and differentiate your business in the marketplace.

Implementing Your Solvent Recycling Program

But how do you get started with solvent recycling, and what steps are involved in implementing a solvent recycling program? Are you ready to take the next steps towards sustainability and profitability? The key steps to implementing a solvent recycling program include:

Assessment: Have you conducted a thorough assessment of your solvent usage, waste generation, and disposal practices? Understanding your current practices and identifying opportunities for improvement is the first step towards implementing a successful solvent recycling program.

Technology Selection: Have you researched solvent recycling machines for sale and selected the technology that best suits your needs? Choosing the right solvent recycling machine is crucial for achieving optimal results and maximizing the return on your investment.

Integration and Training: Are your staff equipped with the knowledge and skills required to operate the solvent recycling equipment safely and effectively? Providing comprehensive training ensures that your team can integrate solvent recycling seamlessly into your existing processes.

Monitoring and Optimization: Are you monitoring the performance of your solvent recycling system and making adjustments as needed to optimize efficiency and effectiveness? Regular monitoring and optimization are essential for maximizing the benefits of solvent recycling and minimizing operating costs.

Choosing the Right Solvent Recycling Machine

When selecting a solvent recycling machine for your business, consider factors such as:

Capacity: Does the machine have the capacity to handle the volume of waste solvent generated by your operations?

Efficiency: Does the machine incorporate features such as automated controls and energy-saving technologies to maximize efficiency and minimize operating costs?

Compatibility: Is the machine compatible with the types of solvents used in your processes, and can it effectively remove contaminants specific to your industry?

Reliability: Is the manufacturer reputable, with a proven track record of delivering high-quality solvent recycling equipment and providing reliable customer support and service?

Implementing a solvent recycling program offers numerous benefits for businesses, including cost savings, environmental protection, regulatory compliance, and enhanced reputation. Are you ready to unlock the potential of solvent recycling and pave the way for a greener, more sustainable future? With solvent recycling machines for sale readily available in the market, there’s never been a better time to embrace sustainable solutions and revolutionize your approach to waste management. Let’s work together to build a brighter, more sustainable future for generations to come.