Introduction to Vertical Blast Drying Ovens

Vertical blast drying ovens represent a significant advancement in drying technology. These innovative devices use vertical airflow to enhance drying efficiency. This section will explore the basic principles of how Laboratory Vacuum Oven operate and why they’re increasingly becoming a popular choice in various industries.

Vertical blast drying oven utilize a unique method of circulating hot air vertically. This design maximizes the use of space and ensures a uniform distribution of heat. The principle behind these ovens is simple yet effective: heated air rises through the chamber, passing over the materials evenly, which results in consistent drying.

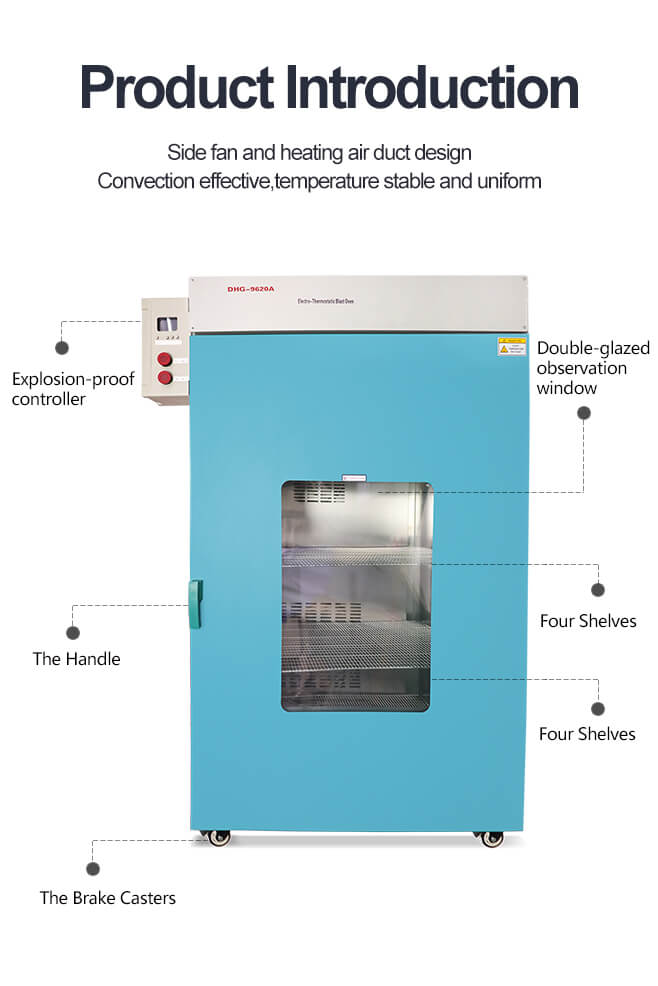

The Design and Structure of Vertical Blast Drying Ovens

The design and structure of vertical blast drying ovens are pivotal to their functionality. In this part, we’ll delve into the components that make up these ovens and how each contributes to their overall performance.

Key components of these ovens include the heating element, air circulation system, and temperature control mechanisms. Their design often incorporates features such as insulated walls to retain heat and glass doors for monitoring the drying process. The vertical structure is not just space-efficient but also aids in better heat distribution.

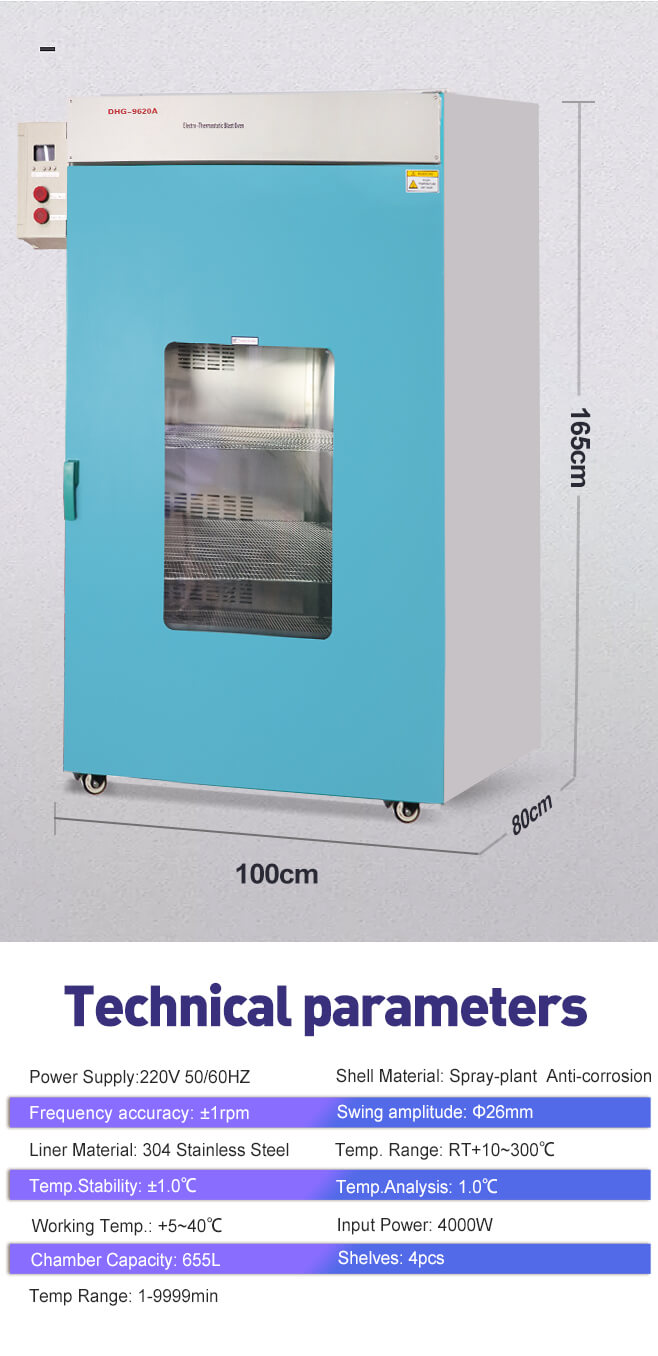

Operational Efficiency and Energy Consumption

Efficiency is a crucial aspect of any industrial equipment, and vertical blast drying oven excel in this area. Here, we will discuss how these ovens achieve high operational efficiency and their impact on energy consumption.

Vertical blast drying ovens are designed to minimize heat loss, thereby conserving energy. The vertical airflow system ensures quick and even drying, reducing the time required for the process. This efficiency translates into lower energy bills, making these ovens an economical choice for businesses.

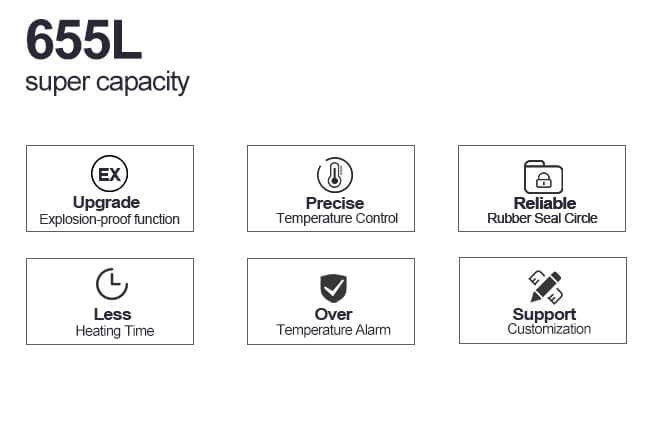

Safety Features and Compliance Standards

Safety is paramount in industrial settings, and vertical blast drying oven are equipped with various safety features. This section will outline these features and how they comply with industry standards.

These ovens often include safety mechanisms like overheat protection, door locks, and alarms. Compliance with safety standards ensures that these ovens provide a safe working environment, making them a reliable choice for various applications.

Maintenance and Longevity

Maintaining industrial equipment is essential for its longevity, and vertical blast drying ovens are no exception. In this part, we will explore the maintenance requirements of these ovens and how proper maintenance contributes to their longevity.

Regular maintenance, such as cleaning the interior and checking the heating elements, ensures that the ovens function efficiently. Proper care and maintenance can significantly extend the lifespan of these ovens, making them a worthwhile investment.

The Future of Drying Technology with Vertical Blast Drying Ovens

As we look towards the future, vertical blast drying oven are set to play a pivotal role in drying technology. This final section will speculate on the future advancements and the potential impact of these ovens on various industries.

With ongoing technological advancements, vertical blast drying ovens are likely to become more efficient, user-friendly, and versatile. They hold the potential to revolutionize drying processes in numerous fields, from pharmaceuticals to food production.

Embracing the Future with ZZKD Machinery and Instrument Equipment Co.,Ltd.

In conclusion, vertical blast drying oven are a testament to the advancements in drying technology. Their efficiency, safety, and innovative design make them an invaluable asset in various industrial applications. For businesses looking to stay ahead in their respective industries, embracing this technology is a step in the right direction. ZZKD Machinery and Instrument Equipment Co.,Ltd. is at the forefront of providing these cutting-edge solutions. To learn more about how these ovens can benefit your business, visit ZZKD’s website and explore their range of high-quality distillation and extraction equipment. Let’s embark on a journey towards more efficient and sustainable industrial processes together!