Solvent Recovery System have become integral in various industries, including laboratory equipment supply, where companies like ZZKD Machinery and Instrument Equipment Co., Ltd. are at the forefront. These systems play a pivotal role in enhancing both operational efficiency and sustainability. In this article, we will explore the importance and functionality of solvent recycler machine and their significant impact on laboratory processes.

Solvent Recovery Systems are designed to reclaim and reuse solvents used in laboratory processes. These systems are especially crucial for ZZKD Machinery and Instrument Equipment Co., Ltd., as a laboratory equipment supplier. Let’s delve deeper into how Solvent Recovery Systems work and their various applications.

How Solvent Recovery System Work

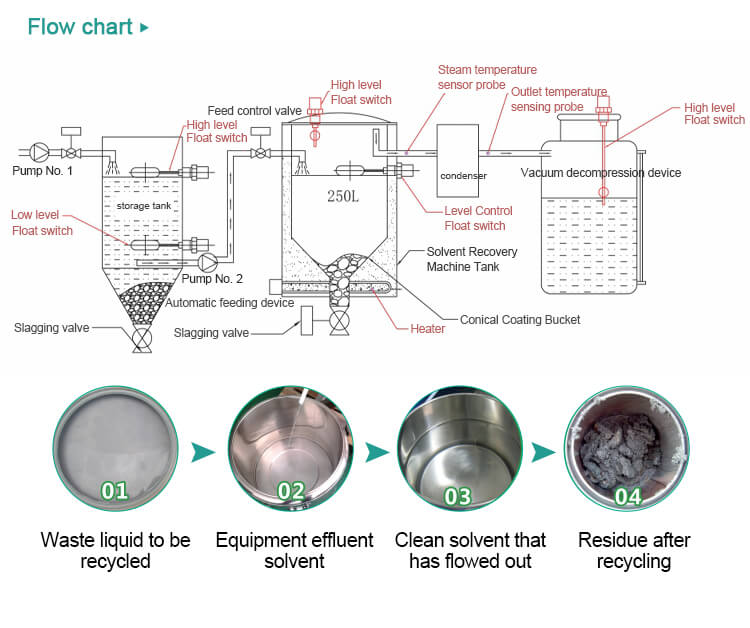

Solvent recovery systems work on the principle of distillation. They separate and collect solvents from process waste streams, allowing them to be reused. These systems consist of several essential components, including distillation units, condensers, and collection vessels.

The process begins by heating the solvent-laden waste stream, causing the solvent to evaporate. The vapor is then condensed back into liquid form, leaving behind the non-volatile waste materials. This recovered solvent can be purified and reintroduced into the production process, reducing the need for new solvent procurement.

Types of Solvent Recovery System

There are several types of solvent recovery systems, each suited to specific industry needs. The two primary categories are batch solvent recovery systems and continuous solvent recovery systems.

Batch systems are suitable for smaller-scale operations and are typically more manual in operation. Continuous systems, on the other hand, are designed for high-volume processes and offer automated, continuous solvent recovery.

Benefits of Solvent Recovery System

The implementation of a solvent recovery system offers numerous benefits to businesses and the environment.

1. Cost Savings: One of the most significant advantages is cost savings. By reusing solvents, companies reduce their expenses associated with purchasing new solvents repeatedly.

2. Environmental Impact: Solvent recovery systems significantly reduce the disposal of hazardous waste, contributing to a cleaner environment and meeting regulatory requirements.

3. Energy Efficiency: Modern solvent recovery systems are designed for energy efficiency, helping companies reduce their carbon footprint.

Applications of Solvent Recovery Systems

Solvent recovery systems find applications in various industries, including:

1. Chemical Industry: Chemical manufacturers use solvent recovery systems to reclaim valuable solvents from waste streams, improving resource efficiency.

2. Pharmaceutical Industry: Solvent recovery is crucial in pharmaceutical manufacturing, ensuring the reuse of expensive solvents used in drug synthesis.

3. Automotive Industry: Automotive paint shops use solvent recovery systems to reduce emissions and save on solvent costs.

Choosing the Right Solvent Recovery System

Selecting the appropriate solvent recovery system for your specific needs is essential. Factors to consider include the type and volume of solvents used, process requirements, and environmental goals.

In conclusion, solvent recovery systems are a fundamental part of modern industrial processes, offering cost savings, environmental benefits, and improved resource efficiency. Choosing the right system for your business can lead to long-term sustainability and profitability.