In today’s era of increasing environmental awareness and sustainability, finding innovative solutions to reduce waste and minimize the ecological footprint has become a top priority. One such groundbreaking invention is the acetone recycling machine. This cutting-edge technology enables the effective reclamation of acetone, a commonly used solvent, from various industrial processes. In this article, we will delve into the workings of acetone recycling machines, explore their applications, and highlight the significant environmental and economic benefits they offer.

I. Understanding Acetone Recycling Machines

1.1 What is an Acetone Recycling Machine?

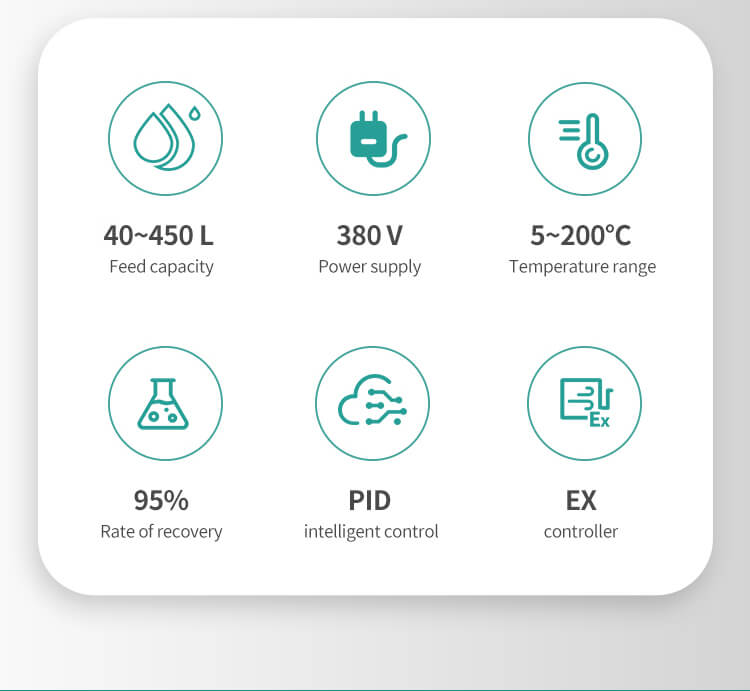

Acetone recycling machines are specialized devices designed to recover and purify acetone, a versatile solvent used in a wide range of industrial applications. These machines utilize advanced distillation and filtration techniques to separate impurities from used acetone, allowing for its reuse instead of disposal.

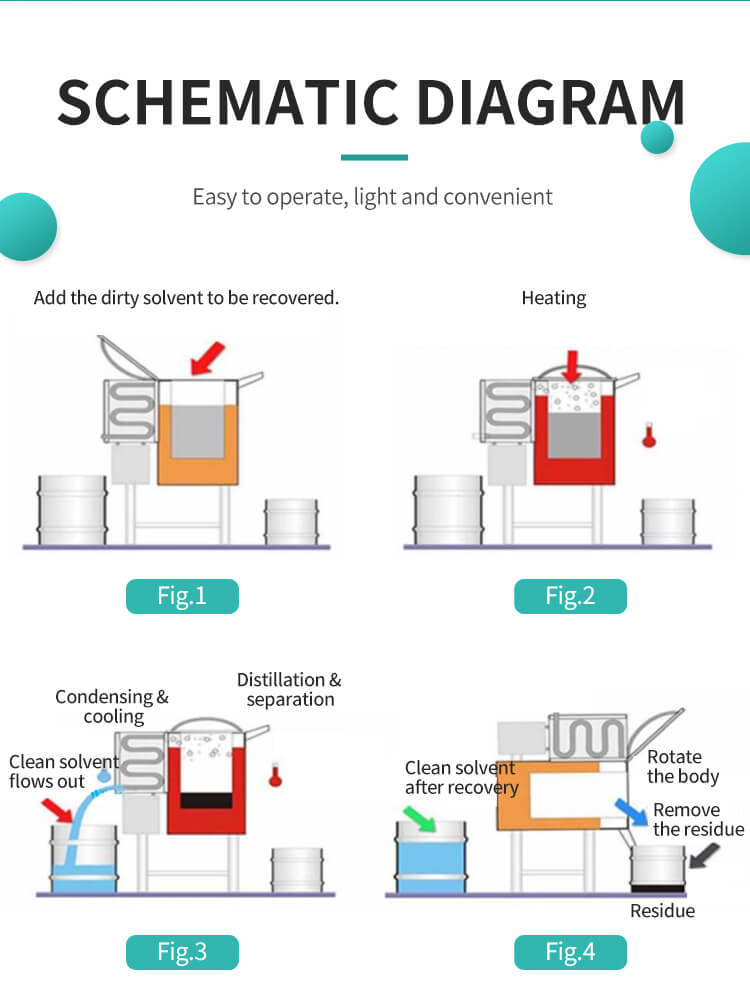

1.2 Working Principle of Acetone Recycling Machines

Acetone recycling machines operate on the principle of distillation, where the solvent is heated to its boiling point, vaporized, and then condensed back into a liquid form. The machine’s distillation chamber separates the impurities from the acetone, ensuring a high-quality end product.

1.3 Key Components of an Acetone Recycling Machine

Typically, an acetone recycling machine consists of several essential components, including a distillation chamber, heating elements, condensers, pumps, and filtration systems. These components work together to ensure the efficient separation and purification of acetone.

1.4 Benefits of Acetone Recycling Machines

Acetone recycling machines offer numerous advantages, including:

– Waste Reduction: By reclaiming and reusing acetone, these machines significantly reduce the amount of solvent waste generated, leading to a more sustainable waste management process.

– Cost Savings: Acetone is a valuable chemical, and recycling it through these machines can lead to substantial cost savings for industries that rely heavily on this solvent.

– Environmental Protection: The recycling of acetone prevents its release into the environment, reducing air and water pollution associated with its production and disposal.

– Energy Efficiency: Acetone recycling machines are designed to operate efficiently, minimizing energy consumption during the distillation and purification process.

II. Applications of Acetone Recycling Machines

2.1 Industrial Applications

Acetone is widely used in various industries, including paints and coatings, pharmaceuticals, chemical manufacturing, and automotive. Acetone recycling machines find extensive applications in these sectors, allowing for the recovery and reuse of acetone, resulting in cost savings and reduced waste generation.

2.2 Laboratory Applications

Laboratories often use acetone as a solvent for cleaning and degreasing equipment. Acetone recycling machines enable laboratories to reclaim and recycle the solvent, providing a sustainable solution and minimizing the environmental impact of their operations.

2.3 Medical Applications

In the medical field, acetone is utilized for sterilization and cleaning purposes. Acetone recycling machines play a vital role in healthcare facilities, where the recovery and reuse of acetone contribute to cost savings and eco-friendly practices.

2.4 Cleaning and Degreasing Industries

Acetone is an effective solvent for removing grease, oil, and other contaminants. Cleaning and degreasing industries can benefit from acetone recycling machines by reusing the solvent, reducing waste, and promoting sustainable practices.

III. Acetone Recycling Machine in the Pharmaceutical Industry

3.1 Overview of the Pharmaceutical Industry’s Acetone Usage

The pharmaceutical industry extensively employs acetone for various processes, including drug formulation, cleaning equipment, and as a solvent in research and development. However, the disposal of large quantities of acetone poses environmental challenges and significant costs.

3.2 Implementation of Acetone Recycling Machine

In a notable case study, a pharmaceutical company implemented an acetone recycling machine within their production facility. The machine effectively recovered and purified acetone, allowing for its reuse in manufacturing processes. This initiative not only reduced the company’s waste generation but also resulted in substantial cost savings.

3.3 Environmental and Economic Impact

The implementation of the acetone recycling machine had a significant environmental impact. It drastically reduced the amount of acetone waste that would have otherwise been disposed of, preventing its release into the environment and minimizing pollution. Moreover, the cost savings achieved through acetone recycling contributed to the company’s economic growth and sustainability.

3.4 Future Prospects and Expansion

The successful implementation of acetone recycling machines in the pharmaceutical industry serves as a promising example for other sectors. As more companies recognize the environmental and economic benefits, the adoption of these machines is expected to increase, leading to a greener and more sustainable future.

IV. Advantages of Acetone Recycling Machines

4.1 Environmental Benefits

Acetone recycling machines play a crucial role in waste reduction and environmental protection. By recovering and reusing acetone, these machines minimize the need for new production, reducing the associated carbon emissions and conserving natural resources.

4.2 Economic Benefits

The cost savings achieved through acetone recycling machines are significant. Industries can substantially reduce their expenses by reusing acetone instead of purchasing new supplies. Additionally, the recycling process can open up new revenue streams, as reclaimed acetone can be sold to other industries.

4.3 Reduction in Carbon Footprint

Acetone recycling machines contribute to the reduction of carbon footprints. By recycling the solvent instead of producing it from scratch, industries can decrease their greenhouse gas emissions, promoting a more sustainable and eco-friendly approach.

4.4 Promoting Sustainable Practices

The adoption of acetone recycling machines aligns with the broader goal of promoting sustainable practices in industries. By embracing these machines, businesses demonstrate their commitment to reducing waste, conserving resources, and protecting the environment.

V. Transitioning Towards a Sustainable Future

5.1 Importance of Waste Management

Efficient waste management is crucial for a sustainable future. Industries must prioritize minimizing waste generation and exploring innovative technologies like acetone recycling machines to ensure responsible disposal and reuse of valuable resources.

5.2 The Role of Acetone Recycling Machines

Acetone recycling machines play a vital role in waste management practices, particularly in industries that rely heavily on acetone. By implementing these machines, companies can reduce their environmental impact, conserve resources, and contribute to a circular economy.

5.3 Collaboration Between Industries and Manufacturers

To drive widespread adoption of acetone recycling machines, collaboration between industries and manufacturers is essential. Companies must work closely with machine manufacturers to develop customized solutions that meet their specific requirements, fostering a more sustainable industrial ecosystem.

5.4 Government Initiatives and Incentives

Governments provide incentives to encourage sustainable practices, playing a key role in promoting the adoption of acetone recovery machines. Incentivize businesses to invest in these machines and accelerate the transition to a greener future.

Understanding the significance of acetone recycling machines in waste management and sustainable practices is crucial in our pursuit of a greener future. These innovative machines not only promote environmental responsibility but also offer substantial economic benefits. As industries and businesses adopt these machines, they contribute to the reduction of carbon footprints and overall waste generation. Collaboration between various stakeholders, including manufacturers, industries, and government bodies, will play a pivotal role in accelerating the adoption of acetone recycling machines and fostering a sustainable future for generations to come.