In the realm of scientific research, industrial manufacturing, and various laboratory processes, precise control over temperature and atmospheric conditions is crucial for achieving desired results. One technology that has gained significant importance in these domains is the vacuum oven. A vacuum oven is a specialized piece of equipment that provides a controlled environment with low pressure and reduced oxygen levels. In this article, we will delve into the concept of a vacuum oven, explore its applications across different industries, and shed light on its benefits.

I. Understanding Vacuum Oven:

A. Definition and Operation:

A vacuum oven, as the name suggests, is an oven that operates under vacuum conditions, where the pressure inside the oven is significantly lower than atmospheric pressure. This is achieved by removing air and other gases from the chamber, creating a controlled environment for heating, drying, and curing processes. Vacuum ovens are typically constructed with a double-wall design to ens ure effective insulation and prevent heat loss to the surroundings.

B. Components and Features:

1. Chamber: The main compartment of a vacuum oven where the materials or samples are placed for processing. It is constructed from a durable and non-reactive material such as stainless steel, ensuring resistance to corrosion and contamination.

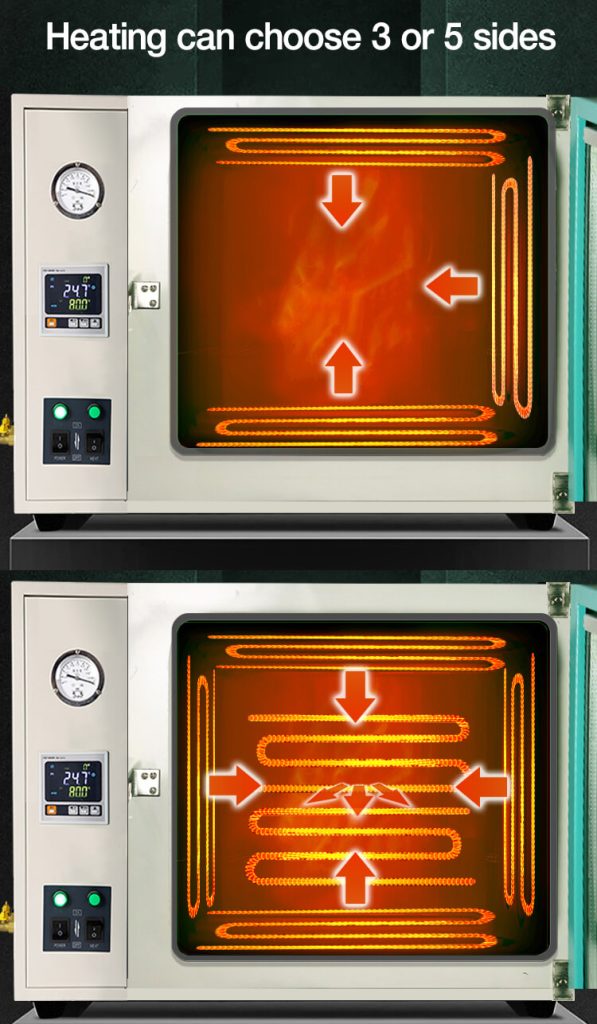

2. Heating System: Vacuum ovens are equipped with a heating system that provides uniform and precise temperature control. Heating elements, often made of nichrome or silicon carbide, are strategically positioned within the chamber to ensure even heat distribution.

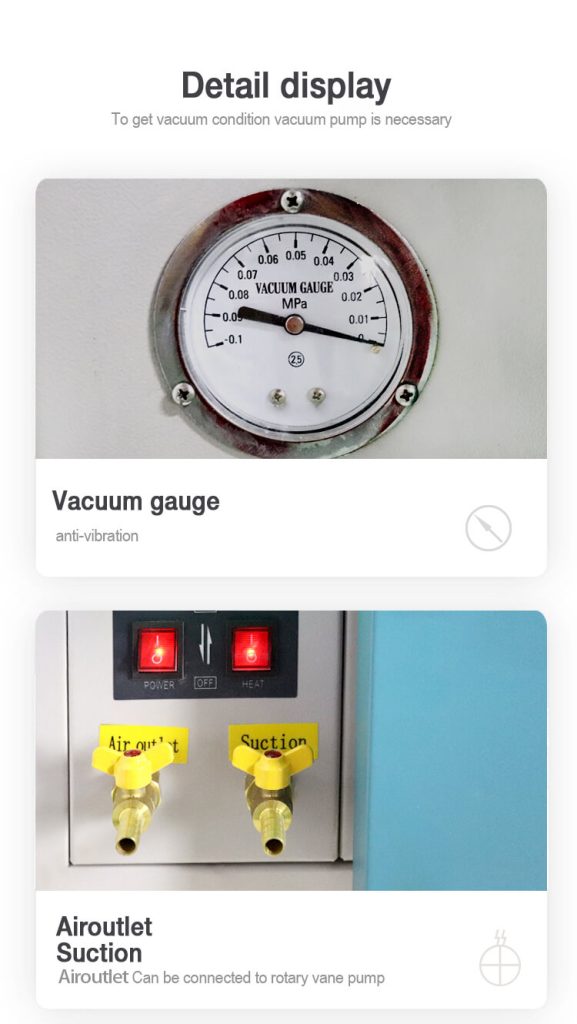

3. Vacuum System: A vacuum pump or system is an integral part of a vacuum oven, responsible for creating and maintaining the desired level of vacuum within the chamber. It removes air and other gases to reduce the pressure, allowing for efficient processing.

4. Control System: Modern vacuum ovens come with advanced control systems that enable users to set and monitor temperature, vacuum levels, and other parameters. These systems often feature digital displays and programmable options for enhanced convenience and accuracy.

II. Applications of Vacuum Oven:

Vacuum ovens find diverse applications across numerous industries, owing to their ability to provide controlled environments with low pressure and reduced oxygen levels. Here are some notable applications:

A. Pharmaceutical Industry:

In the pharmaceutical industry, vacuum ovens are extensively used for various processes such as drying and sterilization of pharmaceutical products, active ingredient purification, and stability testing of drugs. The low-pressure environment in a vacuum oven helps prevent oxidation, degradation, and contamination, ensuring the integrity and quality of the pharmaceutical products.

Application: Vacuum Drying of Medicinal Herbs

An interesting application case of vacuum ovens in the pharmaceutical industry is the drying of medicinal herbs. Companies often utilize medicinal herbs like chamomile or lavender for producing herbal supplements or as raw materials in pharmaceutical formulations.Vacuum drying offers a gentle and efficient method to remove moisture from these herbs while preserving their bioactive compounds. Subjecting the herbs to controlled low-pressure conditions accelerates the drying process without causing significant degradation or loss of beneficial compounds.

B. Materials Research and Semiconductor Industry:

Vacuum ovens play a vital role in materials research, especially for heat treatment and processing of sensitive materials. The semiconductor industry relies on vacuum ovens for degassing, drying, and curing processes of high-purity materials in device fabrication. In a vacuum oven, the controlled environment removes impurities and moisture, preventing defects and enhancing semiconductor component quality.

C. Food Industry:

The food industry employs vacuum ovens for various purposes, including dehydration, sterilization, and flavor enhancement. Vacuum drying preserves nutrients, color, and flavor, extending shelf life of fruits, vegetables, and other food products. Vacuum ovens aid in vacuum packaging, inhibiting spoilage-causing microorganisms and maintaining food freshness by removing air from packages.

III. Benefits of Vacuum Oven:

A. Enhanced Product Quality:

The controlled environment provided by vacuum ovens offers several benefits that contribute to enhanced product quality. By operating under low pressure and reduced oxygen levels, vacuum ovens prevent oxidation, minimize the formation of unwanted byproducts, and preserve the integrity of sensitive materials. This leads to higher-quality end products with improved properties and extended shelf life.

B. Precise Temperature Control:

Designers create vacuum ovens to provide precise temperature control, ensuring uniform heat distribution throughout the chamber. This precise control is crucial for sensitive processes where temperature variations can impact the final product quality. The ability to set and maintain specific temperature profiles in a vacuum oven enables researchers and manufacturers to achieve consistent results.

C. Faster Processing:

The use of vacuum ovens often accelerates processing times compared to traditional methods. The low-pressure environment and efficient heat transfer within the chamber promote faster evaporation, drying, or curing of materials. This not only increases productivity but also reduces energy consumption, making vacuum ovens a cost-effective solution.

D. Versatility and Adaptability:

Vacuum ovens offer versatility in accommodating a wide range of materials and applications. With adjustable temperature and vacuum settings, these ovens can handle different processes and materials, making them suitable for diverse industries. The adaptability of vacuum ovens ensures they can meet specific requirements and process a variety of samples or products.

Vacuum ovens have become indispensable tools in various industries, providing controlled environments with low pressure and reduced oxygen levels. Their applications range from pharmaceutical drying to materials research and food preservation. With enhanced product quality, precise temperature control, faster processing times, and versatility, vacuum ovens continue to play a crucial role in advancing scientific research, manufacturing processes, and ensuring high-quality end products. As technology progresses, we can expect further innovations in vacuum oven design and features, enabling even more precise control and improved efficiency in a wide range of applications.